rudy0498

Well-Known Member

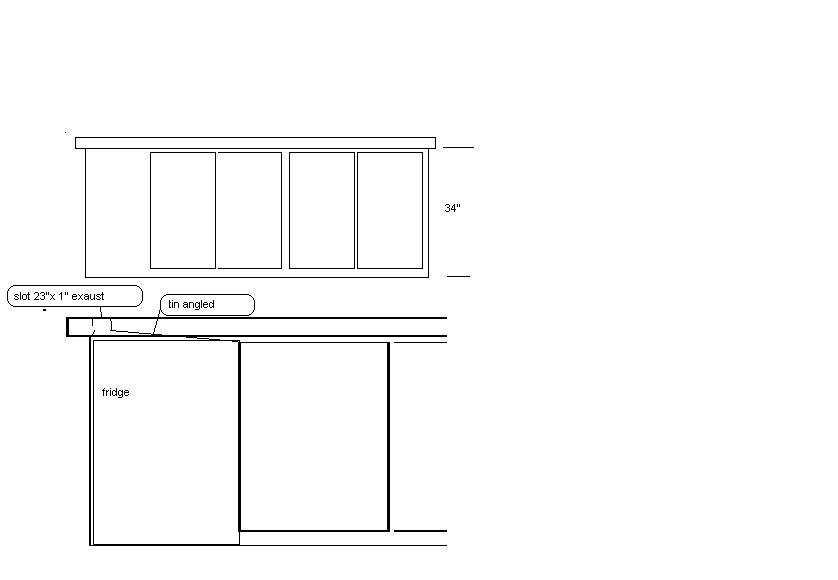

I'm getting ready to embark on what I see to be a pretty ambitious project to build a cold box style kegerator into my already existing bar. I'm going to have to tear my baby apart a bit to make this work because I didn't design it with a kegerator in mind. Logistically, I believe that I have worked everything out from a construction perspective, but I have some worries about how successful this setup will be. I don't know if I will be able to sustain a cold enough temperature and whether or not the compressor of the fridge can handle it without burning out.

I have an older (but not crazy old) Haier mini-fridge that I'm guessing is about 4.5-5 cubit feet. (I would turn this into a kegerator, but even with modifications it's not big enough to hold 2 cornies because the compressor doesn't allow enough floor space.) Anyway, the interior dimensions of the cold box will be roughly 27"(W)X17"(D)X30"(H). That will add roughly 8 cubic feet for a total of 13. So will my compressor be able to handle 13 cubit feet if I insulate it with 2" R10 foam board and seal it up nice and tight?

I really want to make this work because having a cold box would allow me to expand my setup to as many as 6 cornies eventually if I choose to do so. If I do a conventional kegerator I won't be able to expand it. I put way to much time and money into my bar to scrap it and build a new one, and I don't have room for a keezer. BUT, I don't want to put all this time and effort into this and risk damaging my bar if it isn't going to work.

Any engineers out there who know more about this crap than I do have a theory? Or anyone with a similar experience?

I have an older (but not crazy old) Haier mini-fridge that I'm guessing is about 4.5-5 cubit feet. (I would turn this into a kegerator, but even with modifications it's not big enough to hold 2 cornies because the compressor doesn't allow enough floor space.) Anyway, the interior dimensions of the cold box will be roughly 27"(W)X17"(D)X30"(H). That will add roughly 8 cubic feet for a total of 13. So will my compressor be able to handle 13 cubit feet if I insulate it with 2" R10 foam board and seal it up nice and tight?

I really want to make this work because having a cold box would allow me to expand my setup to as many as 6 cornies eventually if I choose to do so. If I do a conventional kegerator I won't be able to expand it. I put way to much time and money into my bar to scrap it and build a new one, and I don't have room for a keezer. BUT, I don't want to put all this time and effort into this and risk damaging my bar if it isn't going to work.

Any engineers out there who know more about this crap than I do have a theory? Or anyone with a similar experience?