Monster Mash

Well-Known Member

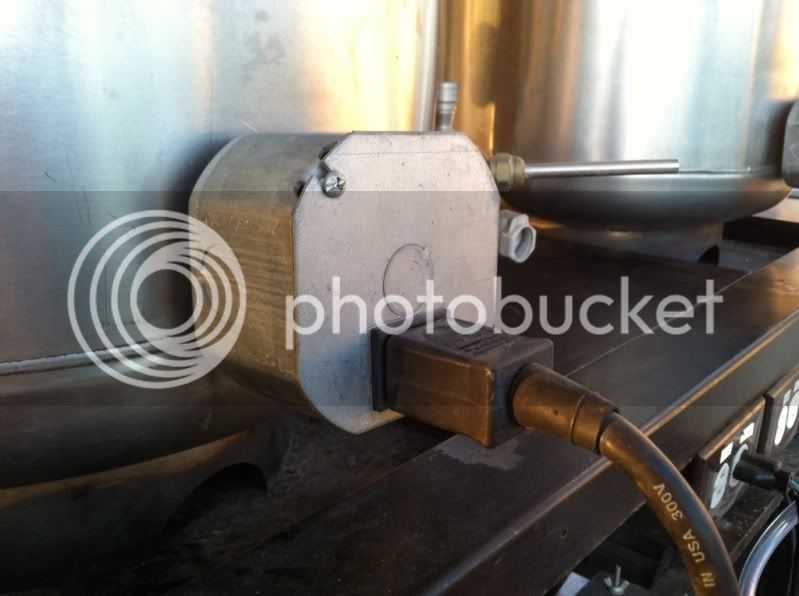

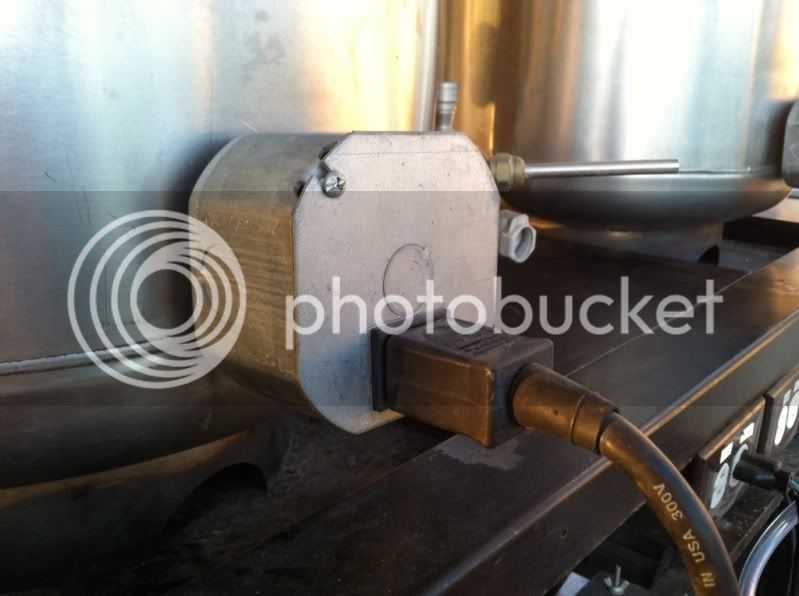

I had some people over watching my brew day and I wasn't paying attention to my HLT level. I heard a POP! from the breaker and immediately knew I ran it dry. I need to somehow have an auto shut off when the water gets low so this doesn't happen again, the elements are only about $12 but it's a pain to replace.