The RPi is a fully enabled (I'm using Adafruit's I2C-enabled Debian distro) Linux computer that is very easy to configure as a full LAMP (Linux/Apache/Mysql/PHP or Python) webserver, and at $35-$40, it's the same price or less than an ethernet shield. With the addition of an inexpensive USB wireless ethernet dongle it's a very effective wireless server, something that, while doable with the right arduino shield, is still pretty pricey.

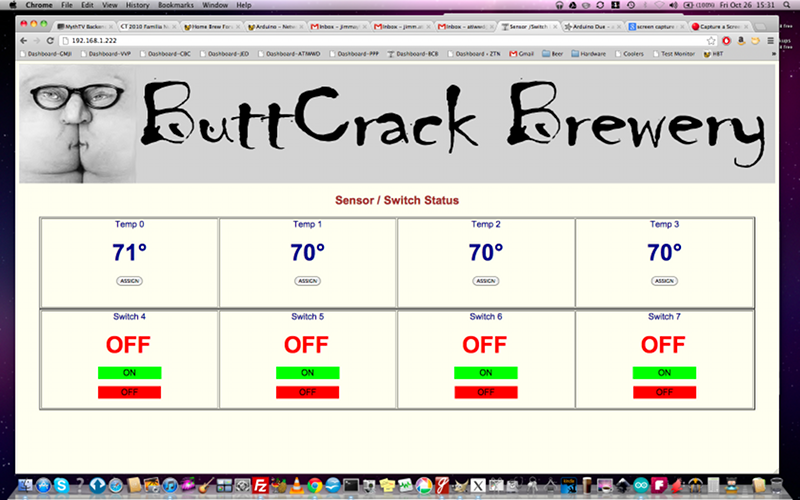

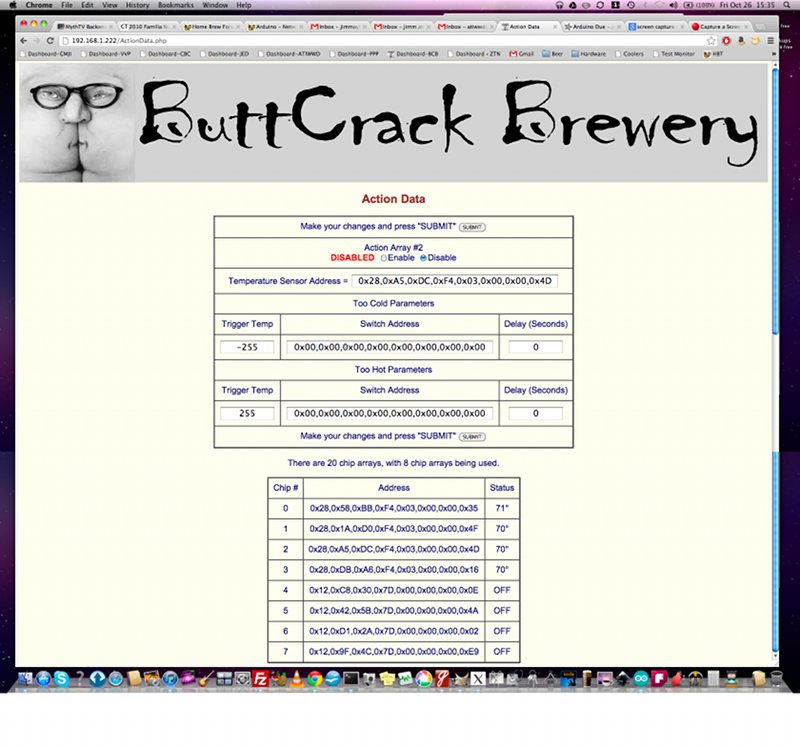

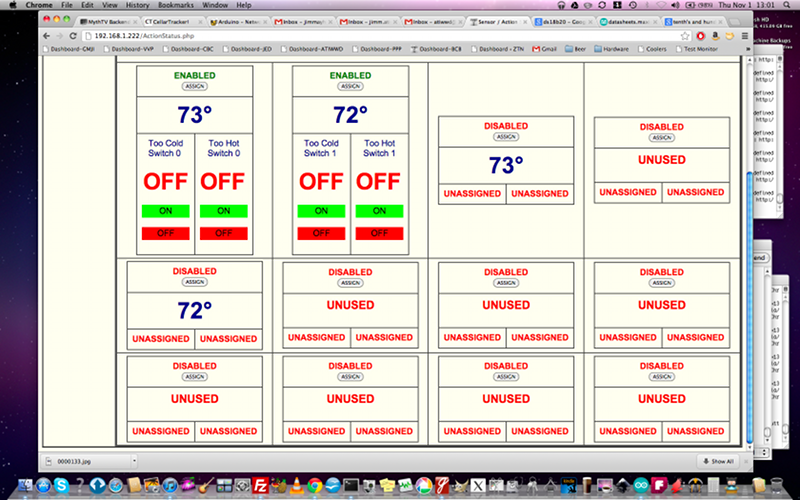

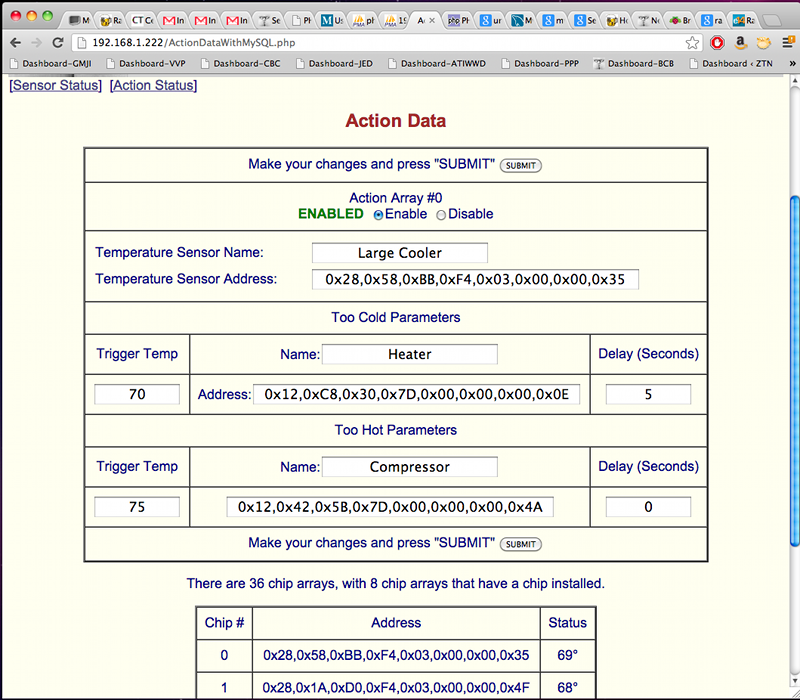

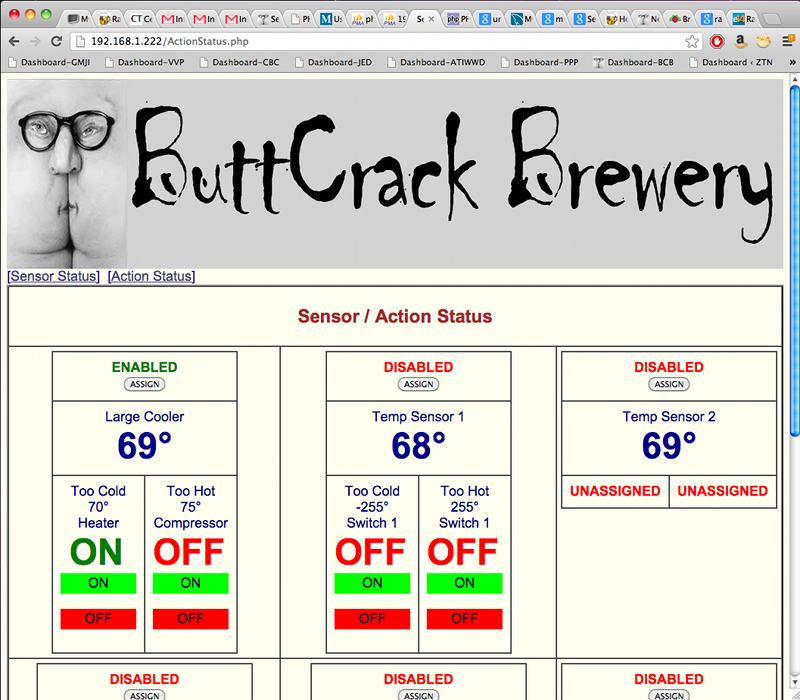

With the RPi doing the web-intensive stuff, and the Arduino doing the I/O intensive operations, it should be pretty easy to set up a complete brewing/fermentation/storage system that can be accessed locally or remotely.

Plus, I'm a beer/wine/computer geek, a truly dangerous combination

With the RPi doing the web-intensive stuff, and the Arduino doing the I/O intensive operations, it should be pretty easy to set up a complete brewing/fermentation/storage system that can be accessed locally or remotely.

Plus, I'm a beer/wine/computer geek, a truly dangerous combination