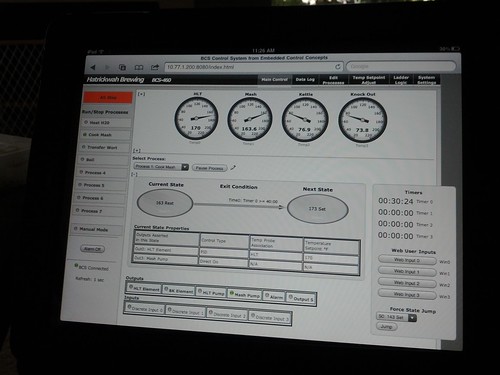

hatrickwah

Sponsor

lschiavo said:Is your meter accurate? If it's digital, I have a few that are all over the place. I have a good old analog meter that I use when it's critical. Test with another meter if you can.

Just have a cheap digital. It's been pretty good, but not great. Nothing else in the house has issues with power, so I'll move forward, over engineer the design and go from there. Once the system is put together, I'll stress test it to see the limits, I'm fine with one element only at a time, but both would be icing on the cake.