mramann

Active Member

- Joined

- Nov 11, 2008

- Messages

- 38

- Reaction score

- 1

Hey kids,

Building a new weldless keggle, and looks like I may have gone just a bit too big with the unibit (step drill). I only went to the recommended 7/8" but I probably should have stopped at 3/4".

When filled with hot water, the build doesn't leak too badly, but there's definitely a drip on the outside. I've sealed it up with plumber's tape, and that doesn't work really well. When the valve is opened the leak gets much worse.

I'm afraid that I'll have to get it welded now. Anyone have any thoughts?

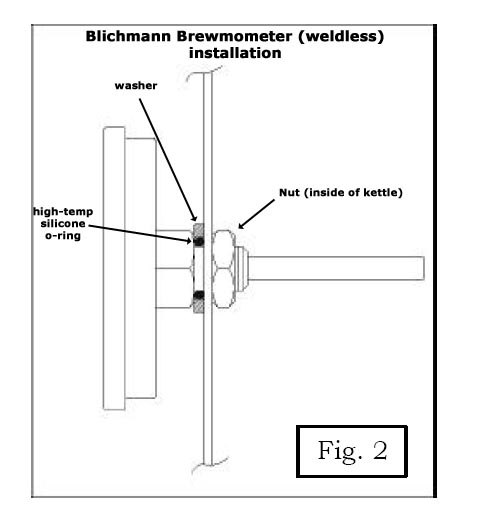

Here are the parts, from the inside to the outside:

Bazooka screen

1/2" coupler

1/2" by 1" closed nipple

Lockdown nut

High-temp O ring

Keg wall

High-temp O ring

Lockdown nut

1/2" ball valve

Many thanks.

Building a new weldless keggle, and looks like I may have gone just a bit too big with the unibit (step drill). I only went to the recommended 7/8" but I probably should have stopped at 3/4".

When filled with hot water, the build doesn't leak too badly, but there's definitely a drip on the outside. I've sealed it up with plumber's tape, and that doesn't work really well. When the valve is opened the leak gets much worse.

I'm afraid that I'll have to get it welded now. Anyone have any thoughts?

Here are the parts, from the inside to the outside:

Bazooka screen

1/2" coupler

1/2" by 1" closed nipple

Lockdown nut

High-temp O ring

Keg wall

High-temp O ring

Lockdown nut

1/2" ball valve

Many thanks.