After much help from these forums, and my pre-build thread found here, my build is complete!

It is a 20 gallon, 5500watt Camco powered, Auber PID controlled BIAB Brewery.

It seems I can do 10 gallons final product of a high gravity brew on it. I think I could kick it up to 12 or 13 with lower gravities.

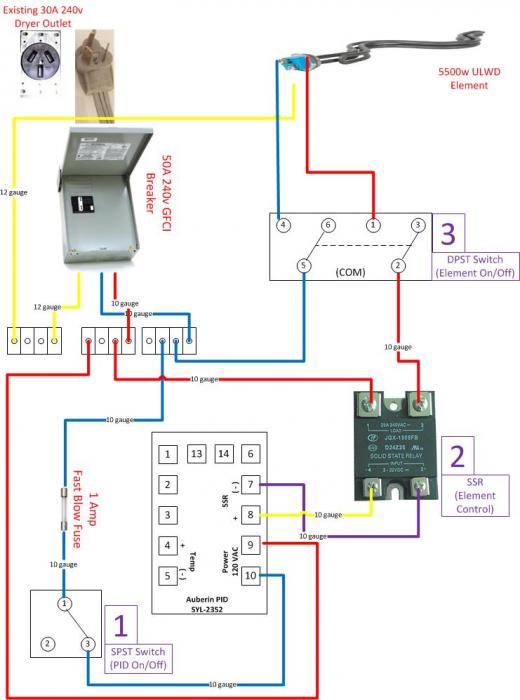

First, I will show my plans. Attached is the brewery layout, and the electrical diagram (Thanks PJ!). For more detail, see the thread above, or ask questions here!

It is a 20 gallon, 5500watt Camco powered, Auber PID controlled BIAB Brewery.

It seems I can do 10 gallons final product of a high gravity brew on it. I think I could kick it up to 12 or 13 with lower gravities.

First, I will show my plans. Attached is the brewery layout, and the electrical diagram (Thanks PJ!). For more detail, see the thread above, or ask questions here!