willynilly

Well-Known Member

Offered is my latest creation, a 100% stainless steel Brutus 20 based on Blichmann Boilermakers and utilizing the BCS 460 control interface. The control box also houses a wireless bridge so that you can control/monitor your brewing system from anywhere with internet access.

Price $5000

Compare to the BrewMagic with RIMS capability at $7000. This system is the most powerful (look at the heating times) HBing system I have seen in my 6 years AG brewing. There is nothing out there commercially with this sort of power, and I have seen nothing built by another HBer with it either.

System Specifications:

(2) 15 gallon Blichman Boilermakers (MLT and BK)

(1) AutoSparge (MLT)

(1) Button False Bottom (MLT)

(1) 304 SS 16ga TIG Welded Stand (48"L x 24"D x 25"H)

(1) 9000W Double Barrel RIMS heater, with drain (capable of heating 10 gallons from 60F to 165F in 18 minutes!)

(1) 9000W (13 gallons from SPARGE temp. to BOIL in 10 minutes!)

(4) 250lb Capacity Casters, (2) with top brakes

Tri Clamp Fittings

50' x 1/2" SS Chiller Mounted in BK with TriClamp Fittings for easy removal

1/2" BK Recirculation Port

All Ball valves are 304 SS 3pc. Ball Valves

LG 3-MD-HC Pumps (quieter than a muffin fan, 3x the flow of the March 809! These are NOT el cheapo HBing pumps!)

(1) "Brain" Control Box. Housed in this 12" x 12" x 6" box are:

10-SSRs (8 40A SSRs, 2 25A SSRs)

8-Heatsinks (mounted to 40A SSRs)

1-Distribution Block

1-Grounding Bar

1-105CFM Muffin Fan

3-Fuses (2 for pumps, 1 for BCS & Wireless Bridge)

5-Cooling Intake Ports (shielded, on underside of control box)

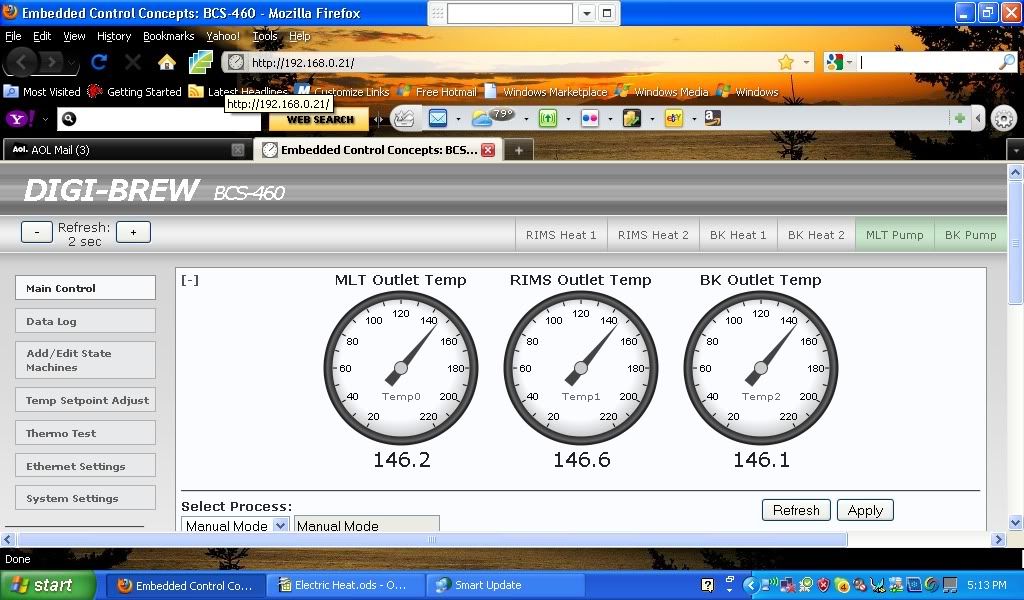

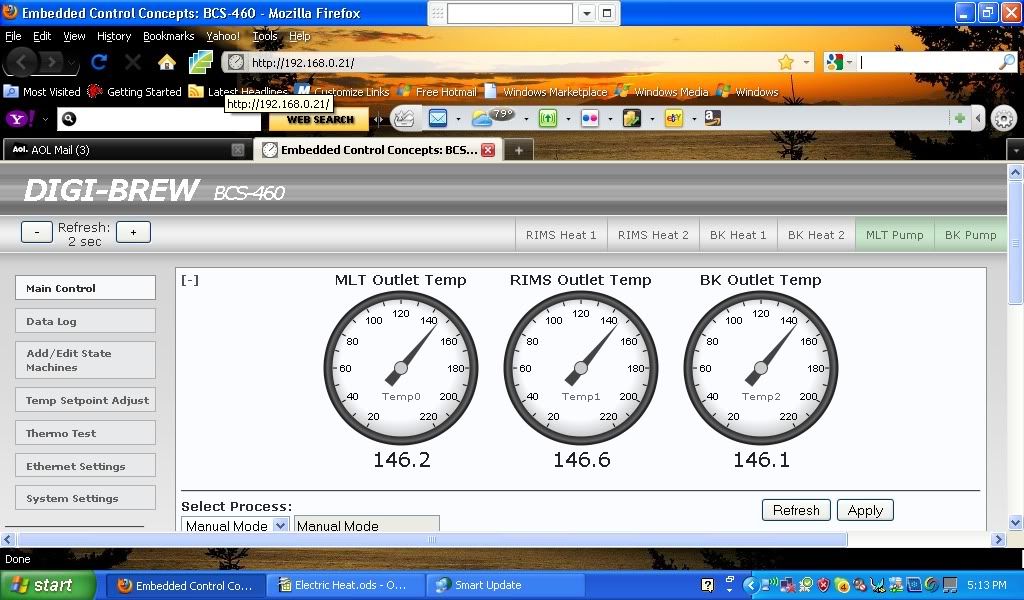

The BCS monitors:

MLT Outlet temp. (this is also the RIMS inlet temp.)

RIMS Outlet temp.

BK Outlet temp.

The BCS allows you to easily automate your processes, or with one click, run the entire brew session manually.

Stuck mash? Worried about the RIMS burning itself up? No worries, the BCS will not allow this. When going from FULL flow to NO flow through the RIMS heater with 9000W of heating power, the BCS will shut down the RIMS heater when the temp. exceeds its set point by 1F. This will protect your investment and your brew session, from disaster.

Price $5000

Compare to the BrewMagic with RIMS capability at $7000. This system is the most powerful (look at the heating times) HBing system I have seen in my 6 years AG brewing. There is nothing out there commercially with this sort of power, and I have seen nothing built by another HBer with it either.

System Specifications:

(2) 15 gallon Blichman Boilermakers (MLT and BK)

(1) AutoSparge (MLT)

(1) Button False Bottom (MLT)

(1) 304 SS 16ga TIG Welded Stand (48"L x 24"D x 25"H)

(1) 9000W Double Barrel RIMS heater, with drain (capable of heating 10 gallons from 60F to 165F in 18 minutes!)

(1) 9000W (13 gallons from SPARGE temp. to BOIL in 10 minutes!)

(4) 250lb Capacity Casters, (2) with top brakes

Tri Clamp Fittings

50' x 1/2" SS Chiller Mounted in BK with TriClamp Fittings for easy removal

1/2" BK Recirculation Port

All Ball valves are 304 SS 3pc. Ball Valves

LG 3-MD-HC Pumps (quieter than a muffin fan, 3x the flow of the March 809! These are NOT el cheapo HBing pumps!)

(1) "Brain" Control Box. Housed in this 12" x 12" x 6" box are:

10-SSRs (8 40A SSRs, 2 25A SSRs)

8-Heatsinks (mounted to 40A SSRs)

1-Distribution Block

1-Grounding Bar

1-105CFM Muffin Fan

3-Fuses (2 for pumps, 1 for BCS & Wireless Bridge)

5-Cooling Intake Ports (shielded, on underside of control box)

The BCS monitors:

MLT Outlet temp. (this is also the RIMS inlet temp.)

RIMS Outlet temp.

BK Outlet temp.

The BCS allows you to easily automate your processes, or with one click, run the entire brew session manually.

Stuck mash? Worried about the RIMS burning itself up? No worries, the BCS will not allow this. When going from FULL flow to NO flow through the RIMS heater with 9000W of heating power, the BCS will shut down the RIMS heater when the temp. exceeds its set point by 1F. This will protect your investment and your brew session, from disaster.