Bigscience

Well-Known Member

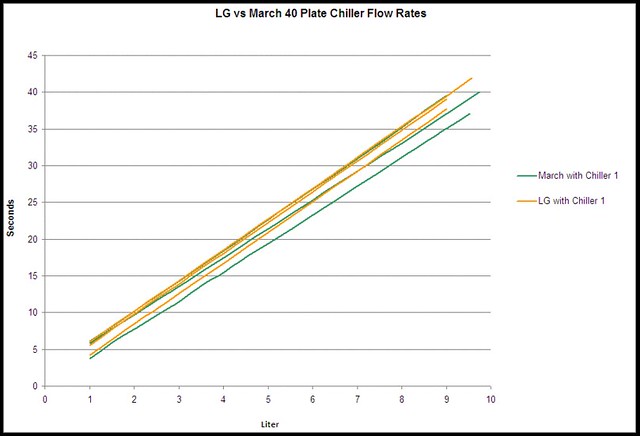

After a recent thread I saw here about pump alternatives to the March 809, I decided to put the facts out there so people have a reference source. Disclaimer, I own 2 LG 3-MD-MT-HCs and have had no problems for over 12 years. I have never used or seen a March 809 in use.

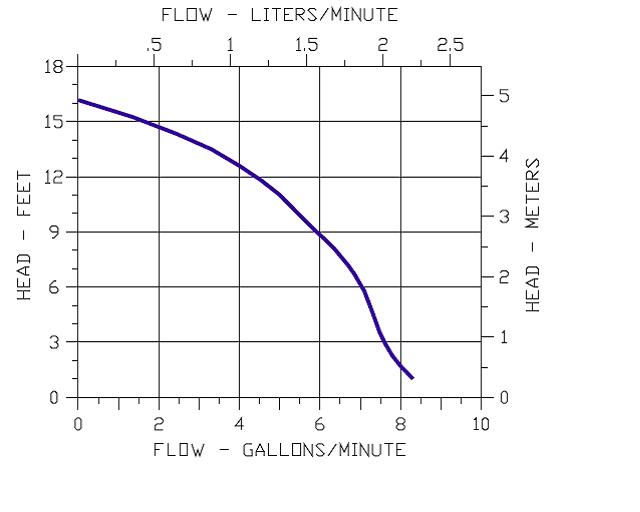

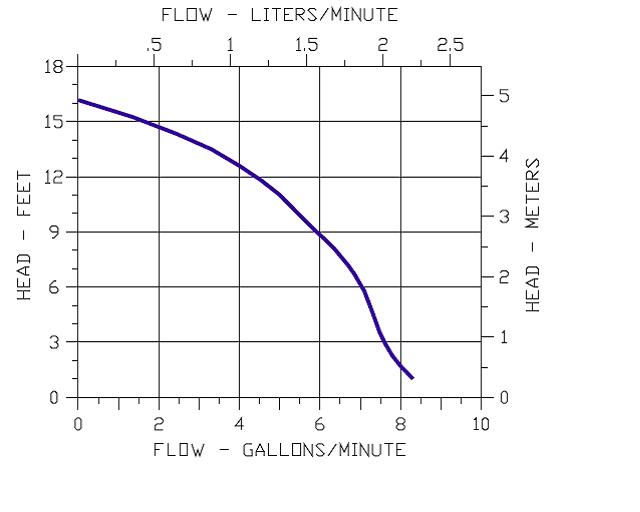

LG 3-MD-MT-HC

Thermally Protected, Open, Fan-Cooled Motor

Sleeve Bearings

6' Power Cord with 3-Prong Plug

Specific Gravity to 1.1

Fluid Temperature to 200 Degrees F.

Ambient Air Temperature to 77 Degrees F.

Run-dry capability up to 8 hours

NOTE: Consult your local distributor or the

factory for applications with higher ambient

temperatures, specific gravities and viscosities.

Motor ..................................1/25 HP Open FC

RPM ..................................3100

Maximum flow rate ..............8.5GPM

Maximum Head ....................16.2

Intermittent Liquid Temp. ....200ÞF

Specific gravity ....................1.1

Intake ..................................1/2 MNPT

Discharge ............................1/2 MNPT

Magnet Housing ..................Glass-filled Polyphenylene Sulfide (e.g. Ryton®)

Volute ..................................Glass-filled Polyphenylene Sulfide (e.g. Ryton®)

Impeller Assembly ................Glass-filled Polyphenylene Sulfide (e.g. Ryton®) w/carbon bushing

O-ring ..................................Viton®

Thrust washers ....................Ceramic

Shaft....................................Ceramic

Weight (lbs.) ......................6.5

Electrical

578603 ....................115V, 50/60Hz, 1.3 amps,

94 watts, 1PH 6 power cord, 3-prong plug.

While the LG is only rate to 200F the materials are rated well above this. It should also be noted that Ryton is also used in the March 809.

Polyphenylene sulfide (Ryton) is an engineering plastic, a high-performance thermoplastic. PPS can be molded, extruded, or machined to high tolerances. In its pure solid form, it may be opaque white to light tan in color. Maximum service temperature is 218 °C (424 °F). PPS has not been found to dissolve in any solvent at temperatures below about 200 °C (392 °F).

PUMP CONSTRUCTION

The patented Little Giant magnetic drive pump design consists of a cylindrical drive magnet attached to the motor shaft which rotates around a chemical resistant plastic separator housing. Inside this housing is a magnet completely encapsulated in chemical resistant plastic, and is fixed to the impeller. The impeller assembly is free to rotate on a spindle that is supported at both ends. The spindle is held captive and does not turn. Front and rear thrust washers are utilized as wear bearings. The washers are held captive and do not revolve. This prevents wear on the shaft. With the magnetic coupling the motor drives the impeller. This coupling eliminates the conventional shaft seal and its possibility of leakage. Two series are available. The HC series handles highly corrosive chemicals at elevated temperatures because of the unique materials used in its construction. The SC series handles semicorrosive fluids. Both series are available with various size pumps, and are available in 115V or 230V, 50/60 Hz versions. The HC models utilize a carbon bushing between the impeller and spindle. The use of this carbon bushing will allow these pumps (HC series) to run dry (without fluid) for up to eight hours at a time. Do not allow the SC models to run dry. They do not have the carbon bushing and heat build up caused by friction will damage the parts when SC models are run dry. All wetted parts can be serviced by removing 4 wing nuts that hold the volute to the housing. The pump head components can easily be replaced in the field if necessary.

PUMP MATERIALS

The plastic parts on SC series pumps are made of glass filled polypropylene. The plastic parts on the HC series pumps are glass filled Ryton®. The spindle shaft which is stationary and the captive thrust washers (front and rear) are alumina ceramic. The O-ring seal is Buna-N for the SC series, and Viton® for HC series. The HC series utilizes a pure carbon bushing in the impeller to enable the pump to run dry for periods up to eight hours at a time.

INSTALLATION

Your Little Giant pump is delivered to you completely preassembled and pretested from the factory. It is ready for immediate use. The pump may be installed in any position. It may be mounted vertically with the pump head down. Proper plumbing connections should be made, see specification table to determine what size intake and discharge your pump has. Use a thread sealer on all pipe connections and hand tighten only. Note: On HC models a roll of Teflon® pipe seal tape is supplied. Do not use a wrench to tighten the HC model connections, excessive force may damage the plastic part. Make sure the wing nuts are tight before operating the pump. Motor nameplates list all electrical data. Make sure the pump is connected to proper voltage before operating. When wiring pumps with no plug, the green (or green/yellow) wire is the ground. The other two wires are line (live). Do not allow the SC models to run dry (without fluid). However, because the HC models utilize a carbon bushing in the impeller they maybe allowed to run dry for periods up to eight hours at a time. These pumps are not submersible, operate the pumps only in the in-line mode. Do not put the units in liquid. Pump should be installed in a dry area and protected from splash. These pumps are not self priming models, they must be installed so that the pump head (volute) is flooded at the time the pump is to be started. That is, the inlet of the pump must be below the level of the surface of the liquid being pumped. (Figure 1). Do not restrict the intake side of the pump. Connections on the intake side should not be of smaller inside diameter pipe or tubing or hose than the intake inside diameter of the intake thread designation. If reduced flow is required restrict the discharge side. Installing a valve or other type of restriction device on the discharge side is the proper method for reducing flow from the pump. When using a valve the pump can be throttled to provide various flow rates and pressures without harming the motor or the pump parts. The motors on these models contain sleeve type bearings. These bearings should be oiled every six months with two to three drops of S.A.E. 20 weight non-detergent oil. The oil holes are located on top at each end of the motor.

Head (ft) Flow (GPH) Head (m) Flow (LPH)

1 500 0.3 1892.7

3 455 0.9 1722.4

6 425 1.8 1608.8

9 355 2.7 1343.8

15 100 4.6 378.5

Manual:

http://franklin-electric.com/media/documents/993236.pdf

Specifications:

http://franklin-electric.com/media/documents/995778.pdf

LG 3-MD-MT-HC

Thermally Protected, Open, Fan-Cooled Motor

Sleeve Bearings

6' Power Cord with 3-Prong Plug

Specific Gravity to 1.1

Fluid Temperature to 200 Degrees F.

Ambient Air Temperature to 77 Degrees F.

Run-dry capability up to 8 hours

NOTE: Consult your local distributor or the

factory for applications with higher ambient

temperatures, specific gravities and viscosities.

Motor ..................................1/25 HP Open FC

RPM ..................................3100

Maximum flow rate ..............8.5GPM

Maximum Head ....................16.2

Intermittent Liquid Temp. ....200ÞF

Specific gravity ....................1.1

Intake ..................................1/2 MNPT

Discharge ............................1/2 MNPT

Magnet Housing ..................Glass-filled Polyphenylene Sulfide (e.g. Ryton®)

Volute ..................................Glass-filled Polyphenylene Sulfide (e.g. Ryton®)

Impeller Assembly ................Glass-filled Polyphenylene Sulfide (e.g. Ryton®) w/carbon bushing

O-ring ..................................Viton®

Thrust washers ....................Ceramic

Shaft....................................Ceramic

Weight (lbs.) ......................6.5

Electrical

578603 ....................115V, 50/60Hz, 1.3 amps,

94 watts, 1PH 6 power cord, 3-prong plug.

While the LG is only rate to 200F the materials are rated well above this. It should also be noted that Ryton is also used in the March 809.

Polyphenylene sulfide (Ryton) is an engineering plastic, a high-performance thermoplastic. PPS can be molded, extruded, or machined to high tolerances. In its pure solid form, it may be opaque white to light tan in color. Maximum service temperature is 218 °C (424 °F). PPS has not been found to dissolve in any solvent at temperatures below about 200 °C (392 °F).

PUMP CONSTRUCTION

The patented Little Giant magnetic drive pump design consists of a cylindrical drive magnet attached to the motor shaft which rotates around a chemical resistant plastic separator housing. Inside this housing is a magnet completely encapsulated in chemical resistant plastic, and is fixed to the impeller. The impeller assembly is free to rotate on a spindle that is supported at both ends. The spindle is held captive and does not turn. Front and rear thrust washers are utilized as wear bearings. The washers are held captive and do not revolve. This prevents wear on the shaft. With the magnetic coupling the motor drives the impeller. This coupling eliminates the conventional shaft seal and its possibility of leakage. Two series are available. The HC series handles highly corrosive chemicals at elevated temperatures because of the unique materials used in its construction. The SC series handles semicorrosive fluids. Both series are available with various size pumps, and are available in 115V or 230V, 50/60 Hz versions. The HC models utilize a carbon bushing between the impeller and spindle. The use of this carbon bushing will allow these pumps (HC series) to run dry (without fluid) for up to eight hours at a time. Do not allow the SC models to run dry. They do not have the carbon bushing and heat build up caused by friction will damage the parts when SC models are run dry. All wetted parts can be serviced by removing 4 wing nuts that hold the volute to the housing. The pump head components can easily be replaced in the field if necessary.

PUMP MATERIALS

The plastic parts on SC series pumps are made of glass filled polypropylene. The plastic parts on the HC series pumps are glass filled Ryton®. The spindle shaft which is stationary and the captive thrust washers (front and rear) are alumina ceramic. The O-ring seal is Buna-N for the SC series, and Viton® for HC series. The HC series utilizes a pure carbon bushing in the impeller to enable the pump to run dry for periods up to eight hours at a time.

INSTALLATION

Your Little Giant pump is delivered to you completely preassembled and pretested from the factory. It is ready for immediate use. The pump may be installed in any position. It may be mounted vertically with the pump head down. Proper plumbing connections should be made, see specification table to determine what size intake and discharge your pump has. Use a thread sealer on all pipe connections and hand tighten only. Note: On HC models a roll of Teflon® pipe seal tape is supplied. Do not use a wrench to tighten the HC model connections, excessive force may damage the plastic part. Make sure the wing nuts are tight before operating the pump. Motor nameplates list all electrical data. Make sure the pump is connected to proper voltage before operating. When wiring pumps with no plug, the green (or green/yellow) wire is the ground. The other two wires are line (live). Do not allow the SC models to run dry (without fluid). However, because the HC models utilize a carbon bushing in the impeller they maybe allowed to run dry for periods up to eight hours at a time. These pumps are not submersible, operate the pumps only in the in-line mode. Do not put the units in liquid. Pump should be installed in a dry area and protected from splash. These pumps are not self priming models, they must be installed so that the pump head (volute) is flooded at the time the pump is to be started. That is, the inlet of the pump must be below the level of the surface of the liquid being pumped. (Figure 1). Do not restrict the intake side of the pump. Connections on the intake side should not be of smaller inside diameter pipe or tubing or hose than the intake inside diameter of the intake thread designation. If reduced flow is required restrict the discharge side. Installing a valve or other type of restriction device on the discharge side is the proper method for reducing flow from the pump. When using a valve the pump can be throttled to provide various flow rates and pressures without harming the motor or the pump parts. The motors on these models contain sleeve type bearings. These bearings should be oiled every six months with two to three drops of S.A.E. 20 weight non-detergent oil. The oil holes are located on top at each end of the motor.

Head (ft) Flow (GPH) Head (m) Flow (LPH)

1 500 0.3 1892.7

3 455 0.9 1722.4

6 425 1.8 1608.8

9 355 2.7 1343.8

15 100 4.6 378.5

Manual:

http://franklin-electric.com/media/documents/993236.pdf

Specifications:

http://franklin-electric.com/media/documents/995778.pdf