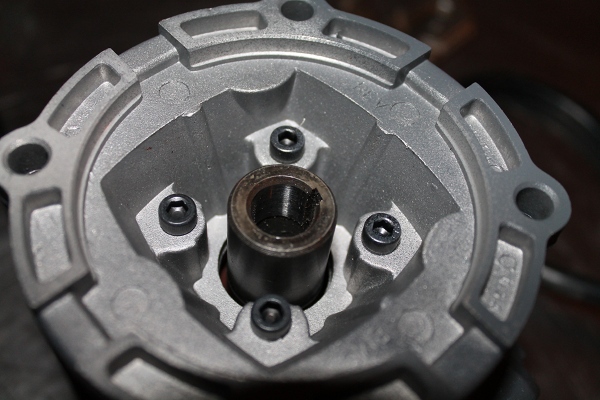

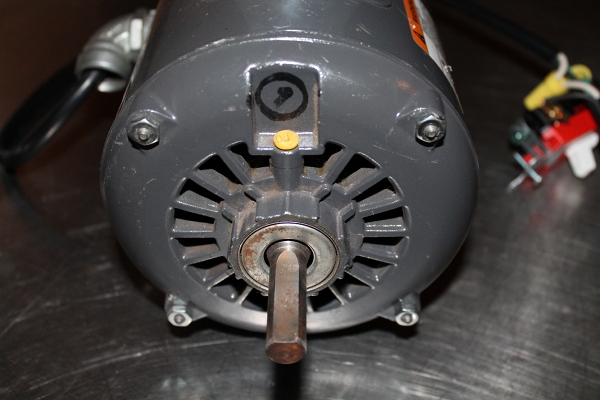

I have 1) Monster Mill with a 1/2" drive shaft, not keywayed but with three flattened sides 2) a motor with 1/2" drive shaft, not keywayed but with a single flattened side and 3) a gear box (reducer) with (a) a 1/2" female input, slotted for a keyway and (b) an output 1/2" drive shaft with a keyway.

Two questions:

1) What is the best way to connect the drive shaft on the mill and drive shaft on the gear box? I was under the impression a coupler was only necessary when the two shafts were a different diameter but I don't know it would work otherwise. Both shafts on the gear box and on the mill do not appear to be removable.

2) When I insert motor shaft into the female slotted input (bow chica wow wow), the shaft slips. If I firmly press the motor and shaft into each other, the shaft does not slip, but I'm afraid any amount of friction from the mill will result in slippage. How do I get the shaft to grasp the slot better?

Two questions:

1) What is the best way to connect the drive shaft on the mill and drive shaft on the gear box? I was under the impression a coupler was only necessary when the two shafts were a different diameter but I don't know it would work otherwise. Both shafts on the gear box and on the mill do not appear to be removable.

2) When I insert motor shaft into the female slotted input (bow chica wow wow), the shaft slips. If I firmly press the motor and shaft into each other, the shaft does not slip, but I'm afraid any amount of friction from the mill will result in slippage. How do I get the shaft to grasp the slot better?