electric heating of the boil kettle:

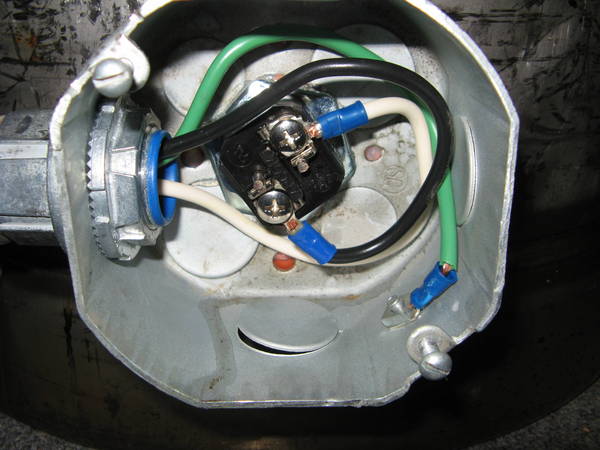

Well I was told today that a propane burner is no longer allowed..... so I'm in need of making an electrically powered boil kettle. I'm thinking something modeled closely off of this: http://home.chattanooga.net/~cdp/boilnew/boilnew.htm

Couple of questions for anyone who has done this, what size element are you using? I'm limited to 4000W @ 240 as I have a spare 240 outlet on a 20A breaker (no idea why so low current on 240). Is that big enough to boil say 10gallons in a reasonable amount of time?

Next what is the importance of the low or extra low density element? The page I linked above mentions that it will help prevent scorching, but is this really a problem?

Just wanted to add. I did some math, and someone please correct me if I'm wrong, but to heat 10 gallons of water (I'll be using less) 40*C (approx difference in temp of all the wort out of mash tun and boiling temp) using a 4000W element:

37850g H2O * 4.1855J * 40C = 6336847 / 4000W = 1584s / 60 = 26.4min

Seems like a good amount of time, especially considering that is assuming no heat loss and 100% eff.

Well I was told today that a propane burner is no longer allowed..... so I'm in need of making an electrically powered boil kettle. I'm thinking something modeled closely off of this: http://home.chattanooga.net/~cdp/boilnew/boilnew.htm

Couple of questions for anyone who has done this, what size element are you using? I'm limited to 4000W @ 240 as I have a spare 240 outlet on a 20A breaker (no idea why so low current on 240). Is that big enough to boil say 10gallons in a reasonable amount of time?

Next what is the importance of the low or extra low density element? The page I linked above mentions that it will help prevent scorching, but is this really a problem?

Just wanted to add. I did some math, and someone please correct me if I'm wrong, but to heat 10 gallons of water (I'll be using less) 40*C (approx difference in temp of all the wort out of mash tun and boiling temp) using a 4000W element:

37850g H2O * 4.1855J * 40C = 6336847 / 4000W = 1584s / 60 = 26.4min

Seems like a good amount of time, especially considering that is assuming no heat loss and 100% eff.