I did a search on the forums, but I can't find a post about a simple PWM controller for stir-plates. I have tested it, and it works great. Any way, here it is:

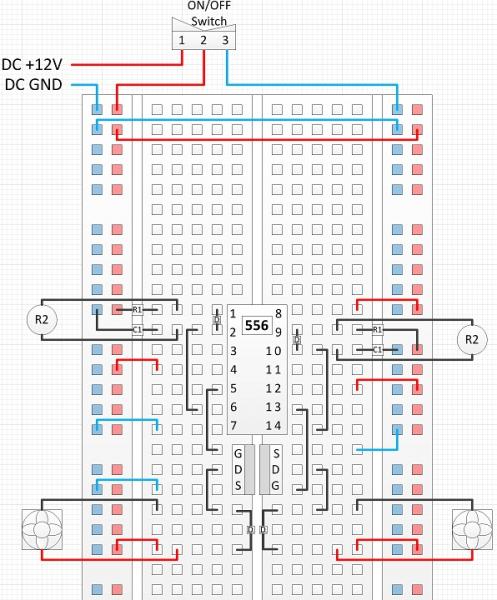

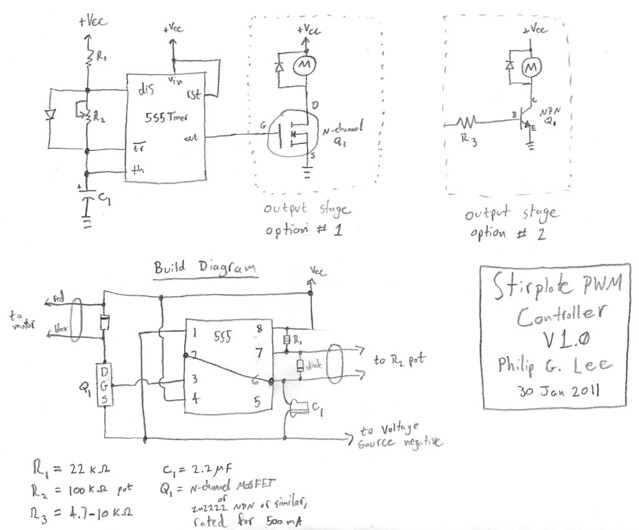

Schematic & Build Diagram

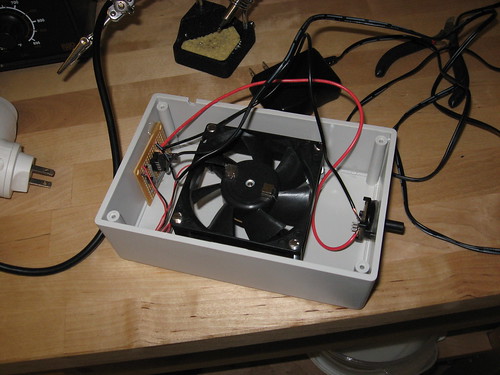

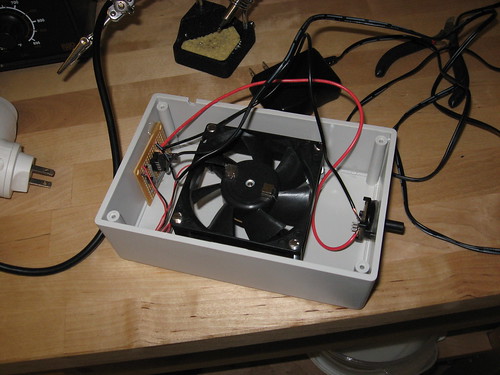

In Action

The 555 can be a cmos 555 (LMC555) or a regular 555 if you like. Q1 is any standard MOSFET (or NPN transistor, like 2n2222) with a current rating of at least whatever your motor is going to suck (mine draws 100 mA). The diodes are standard silicon diodes. The two wires going the pot are connected to its middle pin, and one of the two end pins (which one determines if turning clockwise increases or decreases speed). I have drawn two options for the output stage. I prefer option 1 because MOSFETS are much more efficient, but they can be hard to find in physical stores.

Make sure your Q1 is oriented in the right way (D,G,S for MOSFET, or C,B,E for NPN) by looking at the data sheet or packaging for the component!

I don't know if there's a discussion about the different speed-control methods, but let me put in my two cents about this design versus others.

Resistor voltage division sucks, because most of the power is being dissipated in the resistors. LM-317 regulators are a bit better, but they still cannot get the motor started at voltages less than about 4V, and the top available voltage is 3V less than the power supply, so you only get a narrow range of workability. PWM is the best I can see, because there is very little energy wasted, and the output is always 0V or Vcc, so you get the necessary torque to spin the motor at low speed, and you can push the motor all the way to full speed.

Schematic & Build Diagram

In Action

- R1 = 22k resistor

- R2 = 100k pot (use the middle and one of the end pins)

- R3 = 4.7-10k resistor

- C1 = 2.2 micro-Farads capacitor

- Q1 = N-channel MOSFET

The 555 can be a cmos 555 (LMC555) or a regular 555 if you like. Q1 is any standard MOSFET (or NPN transistor, like 2n2222) with a current rating of at least whatever your motor is going to suck (mine draws 100 mA). The diodes are standard silicon diodes. The two wires going the pot are connected to its middle pin, and one of the two end pins (which one determines if turning clockwise increases or decreases speed). I have drawn two options for the output stage. I prefer option 1 because MOSFETS are much more efficient, but they can be hard to find in physical stores.

Make sure your Q1 is oriented in the right way (D,G,S for MOSFET, or C,B,E for NPN) by looking at the data sheet or packaging for the component!

I don't know if there's a discussion about the different speed-control methods, but let me put in my two cents about this design versus others.

Resistor voltage division sucks, because most of the power is being dissipated in the resistors. LM-317 regulators are a bit better, but they still cannot get the motor started at voltages less than about 4V, and the top available voltage is 3V less than the power supply, so you only get a narrow range of workability. PWM is the best I can see, because there is very little energy wasted, and the output is always 0V or Vcc, so you get the necessary torque to spin the motor at low speed, and you can push the motor all the way to full speed.