You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Single Tier HERMS build

- Thread starter drkwoods

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

drkwoods

Well-Known Member

Frame rate.. sorry bout that! :cross:Lookin good brother. Do the PID displays have a wave effect on them or is it just the frame rate?

drkwoods

Well-Known Member

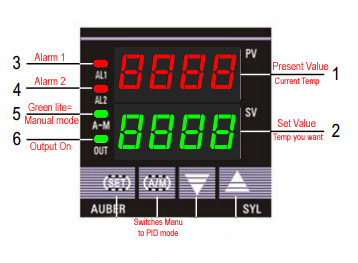

Yes there is a Manual Mode on the PID.. It turns the burner on and off based on time cycles.. ignors temp.. The PID mode and Manual mode can be switched with the push of one button on the PID.. A/M.. If you set it to run in "on-off" (relay or contact) mode then you cannot switch over to manual or PID.. The 3 position switches I have below each PID are to choose what controls the burners, the PID, off or forced on (Manual on, IOW Overides the PID and turns the burner on now).. hope that cleared that part up.You have a switch to change PIDs to manual mode? Isn't it just a button on the screen to do that?

iijakii

Well-Known Member

Yeah, that makes sense. Are you using it for when you're boiling? Seems a bit unnecessary when you can just set the PID to 210 or what have you and then drop down to 80%, 60% whatever is needed in manual mode to maintain boil. Not trying to tell you how to do your rig, it's nicer than mine  . Just trying to understand.

. Just trying to understand.

And I guess the bottom line really is that an extra toggle switch and what not is nickels and dimes in the grand scheme of these builds. Maybe your on-mode helps not having to fiddle with the buttons for a lot of the brewday.

And I guess the bottom line really is that an extra toggle switch and what not is nickels and dimes in the grand scheme of these builds. Maybe your on-mode helps not having to fiddle with the buttons for a lot of the brewday.

drkwoods

Well-Known Member

iijakii said:Yeah, that makes sense. Are you using it for when you're boiling? Seems a bit unnecessary when you can just set the PID to 210 or what have you and then drop down to 80%, 60% whatever is needed in manual mode to maintain boil. Not trying to tell you how to do your rig, it's nicer than mine. Just trying to understand.

And I guess the bottom line really is that an extra toggle switch and what not is nickels and dimes in the grand scheme of these builds. Maybe your on-mode helps not having to fiddle with the buttons for a lot of the brewday.

Yea for the boil I just set it to 211 on/off mode and it kept it simmering nicely, turned off occasionally. I was told by Auber to use the manual mode for the boil and I did try it but since I heat my strike water in the BK (while I heat the HLT to Mash (HEX) temp) I just left it in on/off mode the whole brew day. (changing to PID/Manu would require going thru the settings and IMO during Brewing thats a PITA)

Having the HOA switches is nice for several reasons. It's great for safety since I can kill the flame any time. Also if I accidentlly left the PID in Auto mode and emptied the kettle, it would heat waaaay up and melt my soldered fittings. So I like the shut off to prevent that. Its useful for testing too and forcing the burners on, and if I want to simply get up to temp without any cycling of the burners.

I'm def all about keeping it simple

motobrewer

I'm no atheist scientist, but...

where's you get your handles?

drkwoods

Well-Known Member

motobrewer said:where's you get your handles?

On the control panel?

Home depot in the cabinetry department

motobrewer

I'm no atheist scientist, but...

oh, makes sense, lol

i'm about to start my single tier in a week or so. lot of great ideas from yours!

i'm about to start my single tier in a week or so. lot of great ideas from yours!

motobrewer

I'm no atheist scientist, but...

oh, how did your bleeder valves on your pumps work? did any wort get thru them?

drkwoods

Well-Known Member

yes wort comes out of them when I pull the cable but so does the air.. I might lose a table spoon of wort.. Ive used this method for about 1 year (20 batches) already with good resultoh, how did your bleeder valves on your pumps work? did any wort get thru them?

drkwoods

Well-Known Member

My nephew moved out of state so I never got him to draw up a schematic. I'll put some thing together from my hand written notes soon. (The PID wiring is right out of the instruction manual)wncbrewer said:I hate to be a bother, but did you ever get a wiring diagram? I have really enjoyed following your build

tulsabrewdaddy

Well-Known Member

It looks like your water filter setup is what I'm going to go for, could you post more info on that setup please?

drkwoods

Well-Known Member

tulsabrewdaddy said:It looks like your water filter setup is what I'm going to go for, could you post more info on that setup please?

Well it's two inline home depot whole house filter housings. Ametek filter housings are old but may still be available. I posted the link early in this thread. The first filter is a simple 2 micron general filter and the second is a carbon block I get at the LHBS. I have two in-line ball valves to control flow thru the filters or divert it for washing down the kettles etc. For better pics and the link on the filters please look earlier in this thread.

Edit: Also I had to beef up any silicone hoses running the full pressure tap water. busted a hose and learned this the hard way.. So for that I now use Silbrade hose.. just a 6 foot run since that stuff is $$$

drkwoods

Well-Known Member

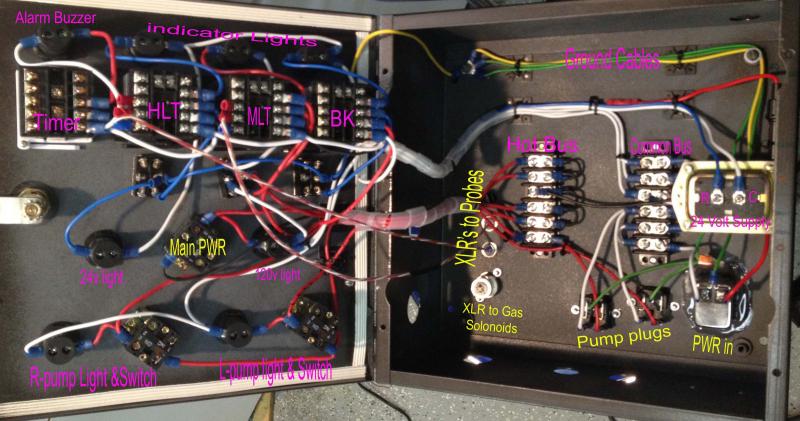

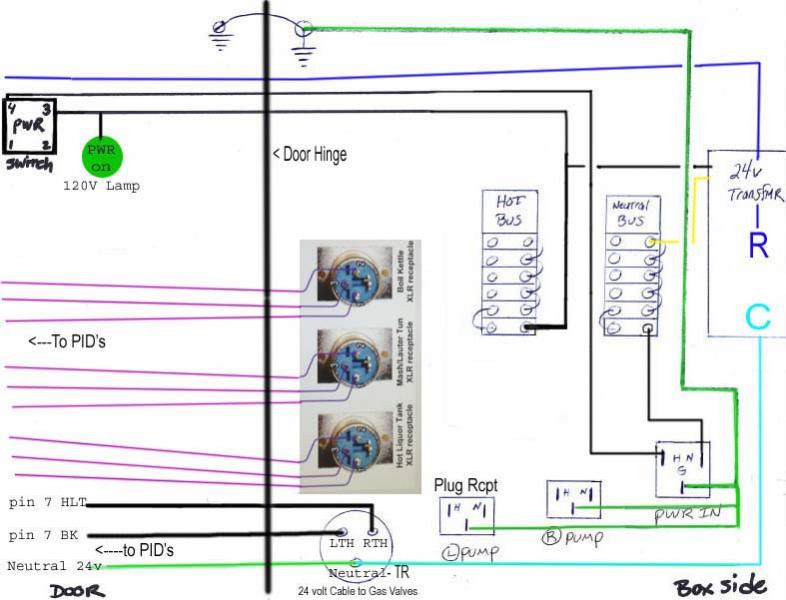

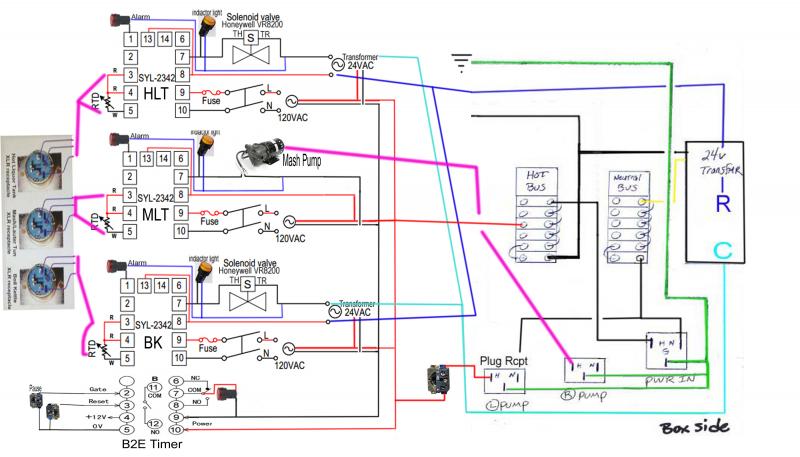

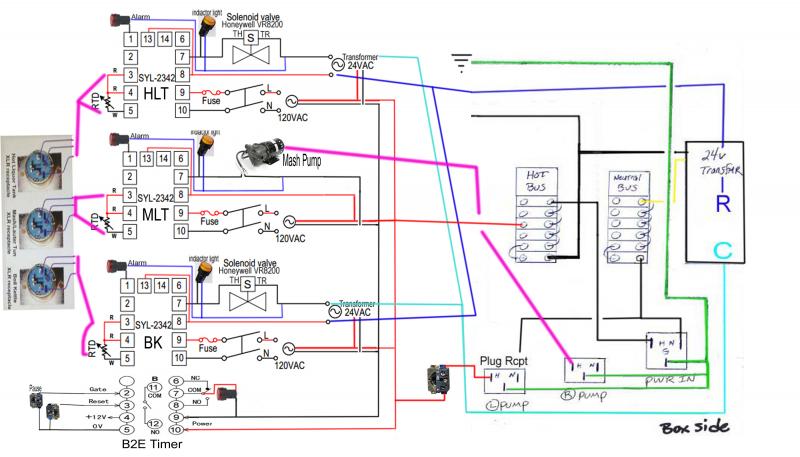

here's the best I have right now.. Its not all on one page and some images are from other schematics I just worked into my design.. Hope these help.. If you have any questions on how I wired something Let me know..I hate to be a bother, but did you ever get a wiring diagram? I have really enjoyed following your build

motobrewer

I'm no atheist scientist, but...

edit: i'm an idiot.

drkwoods

Well-Known Member

here's a crappy basic idea of what I did.. I'll try to clean this up sometime soon

drkwoods

Well-Known Member

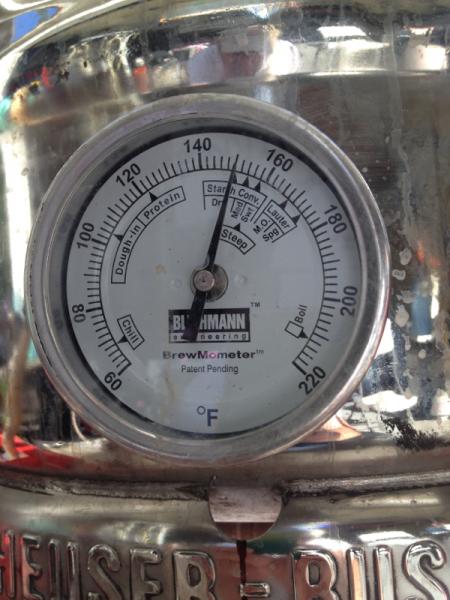

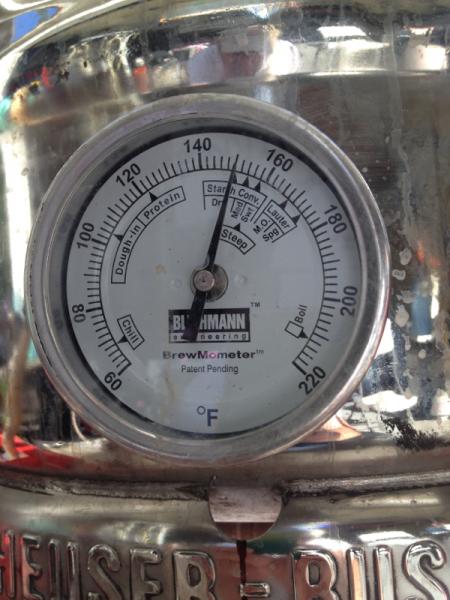

This system is a joy to use. It friggin nails the temps. The Blichman (thermometer in the pic below) is @ the bottom of my MLT, the PID (probe) is just to the right of that thermo and the big dial therm is the HEX out. The MLT delta is 2*f an I am stylin. Drinking my new DIPA called "RIP" cause it's a red IPA / I've been sharing my brews for about a year now with the staff an owner of a very nice restaurant near me. He has approached me now and wants to open a brew pub. So here we go again??

drkwoods

Well-Known Member

Made a Vid showing Mash-out on my system.. and my new Grant idea in testing. Will eventually start a thread on building the Auto Grant and the Auto Sparge

Last edited by a moderator:

drkwoods

Well-Known Member

Last edited by a moderator:

Very cool, were you having trouble with the mash sticking during recirc? Or just wanted a hopback/grant. My build is very simlar, and I have some worries about the grain bed compacting too much since I will be pumping through the herms for the duration of the mash

drkwoods

Well-Known Member

Very cool, were you having trouble with the mash sticking during recirc? Or just wanted a hopback/grant. My build is very simlar, and I have some worries about the grain bed compacting too much since I will be pumping through the herms for the duration of the mash

Ive not had any problems with a stuck mash. I just wanted to run a slower more efficient mash and the Auto-Grant was an idea I had and it works amazing.. Gotta hard wire it now.. I went from 70% efficiency to 85% efficiency just adding the auto sparge and auto grant.. I was never very good at timing the fly sparge addition with the drain speed, and I didint wanna run a throttled down pump for 45 min (too much wear/tear) SO I am stoked, I just did a DIPA with 6oz of Simcoe in the grant basket which has a SS Strainer I made

donnieballgame

Member

Wow nice build! I'm building a single tier RIMS setup and I'm already jealous of your build, a lot of nice features. I love the auto grant, i'll have to keep a lookout for an asparagus steamer, although i'm not going to add a PID for the BK, mostly cause i'm cheap and another 60-80 dollars seems silly to me, but then again, i'm not heating up strike water in my BK, one reason i went with the RIMS system. Keep it up, although I guess your all but done at this point, thanks for the posts, i'm hoping to start a thread on my build, although it's not gonna be this sweet, lol.

drkwoods

Well-Known Member

Thanx DBG! I think the autogrant is one of the best features for multiple reasons but also because I have began first wort additions this way an running the fresh 168 degree wort thru the hops makes a very nice effect on the bitterness I've noticed. Best wishes on your build it's one heck of an adventure

drkwoods

Well-Known Member

Rivenin said:do you have a write up anywhere regarding the auto grant?

Just a YouTube video. I have plans to do a write up. It's got it's moments setting up but I finally got her runnin solid So look for a thread soon

GrantH

Well-Known Member

Do you have any details on how many brew days you get out of your propane tank? I'm looking at electric since it seems like the gas would run through rather quick with 2 burners. Any info is appreciated!

Huaco

Well-Known Member

Do you have any details on how many brew days you get out of your propane tank? I'm looking at electric since it seems like the gas would run through rather quick with 2 burners. Any info is appreciated!

I figured up my electrical cost running two 4500 watt 240 Volt elements for 4 hours (way over estimated) would cost me something like two bucks. I guarantee you cant run two gas burners wide open for four hours that cheap!

I know you weren't asking about energy expense, but I thought I would throw that out there for you to think about.

drkwoods

Well-Known Member

GrantH said:Do you have any details on how many brew days you get out of your propane tank? I'm looking at electric since it seems like the gas would run through rather quick with 2 burners. Any info is appreciated!

I brew 10gal batches usually and I use half a tank per 6 hour session. So I get two brew days or 20gallons of beer out of one $18 propane tank.

Could you explain how Grant thingy upped your efficiency so much and what it is? I didn't see much (or understand?) from write up/videos. looks like just second sparge of MT into another bucket with potentially initial hopping being done??? Would same end result happen with just pumping addl HLT water at slightly higher temp thru MLT and then into BK to fill to preboil levels?

Thanks,

Thanks,

drkwoods

Well-Known Member

Yes. The grant in an of itself does not up efficiency. But it made getting better efficiency much easier. The grant is an intermediate run off from the MT. To get better efficiency I needed a slower sparge, I wanted about 16oz/min or approx 8gal/hour run off. The only way for me to get that wort over to the BK is to pump it. leaving a pump on for an hour was not a good idea. I could also let it gravity flow until equilibrium and then pump the rest. I also could collect the wort in a bucket and keep dumping it over to the BK. I didn't like any of these options and I wanted automation. So when my grant fills with wort runoff it automatically turns on a pump to run it into a fitting at the top of my BK. When the grant empties the auto grant shuts the pump off and it's a hands free sparge (after I get the ball valve set to the runoff speed I desire). I also made a basket where I can set my FWH in there and let the fresh 170*f wort run over the hops continually until I throw them into the BK hop basket after the sparge is complete. So overall this up'd my efficiency because of being able to automate and slow the sparge way down to a predictable and walk away speed.

drkwoods

Well-Known Member

I really like your control panel. Where did you get the skull bezel light from? Ive looked all over the place for one like it and cant seem to find one.

Thanks

Try looking for Motorcycle custom parts I believe this skull was a fuel valve shut off knob that got repurposed. Hope that helps.

drkwoods

Well-Known Member

trango1981

Member

You said you have a March 809 Impeller and a MoreBeer March 815. How much of a performance difference do they have?

I just built an Electric Brewery style system with a HERMs coil in the HLT. My March 809-C pumps are passing about 1.5 gal/min through the coil during the mash recirculation, which in my first run with grains, didn't really set the grain bed. I'm considering ordering the 815 impellers to retro fit my current pumps.

By the way, nice build.

I just built an Electric Brewery style system with a HERMs coil in the HLT. My March 809-C pumps are passing about 1.5 gal/min through the coil during the mash recirculation, which in my first run with grains, didn't really set the grain bed. I'm considering ordering the 815 impellers to retro fit my current pumps.

By the way, nice build.

globetrekker

Member

Wow I really like you herms system and I am going to build something similiar using Stout tanks. Can you tell me how you incorporated your grant tank and how it works ? Very Cool !!!!

drkwoods

Well-Known Member

Wow I really like you herms system and I am going to build something similiar using Stout tanks. Can you tell me how you incorporated your grant tank and how it works ? Very Cool !!!!

Read back a few posts most of the info you want is there. Also check out my youtube video on it http://youtu.be/ps9Bg44j-D8

beerme70

Well-Known Member

Two quick things....1) So, the grant is just something to aid in setting the grain bed, in lue of a manual vorlauf? and 2) What did this set up set you back, if you don't mind me asking.

drkwoods

Well-Known Member

No, it's not for setting the grain bed or skipping a vorlauf. The grant allows the lauter tun to drain slowly (by gravity only) and not be pumped thru a choked down valve to the BK. Previously I would have leave a pump on the entire sparge to pump slowly over to the BK. Now with the grant I set the Lauter tun drain speed to whatever I want and pump over to the BK only when the grant is full. It's simply a collection vessel. There's no pump continuously running and no choked down valve to heat up the pump. ***Also when the grain bed is draining slowly and not being "pulled" by a pump it helps prevent over compaction (of the grain bed) and stuck run offs*** The free flow into a grant is often the main reason for this even in commercial settings. PS: I vorlauf most of the mash and the grant has nothing to do with that, it's only used to facilitate run off during sparge

Sent from my iPad using Home Brew

Sent from my iPad using Home Brew

Similar threads

- Replies

- 1

- Views

- 519

- Replies

- 3

- Views

- 969

For Sale

HERMS hybrid rig and all equipment

- Replies

- 3

- Views

- 376

- Replies

- 4

- Views

- 524

- Replies

- 0

- Views

- 540