jfkriege

Well-Known Member

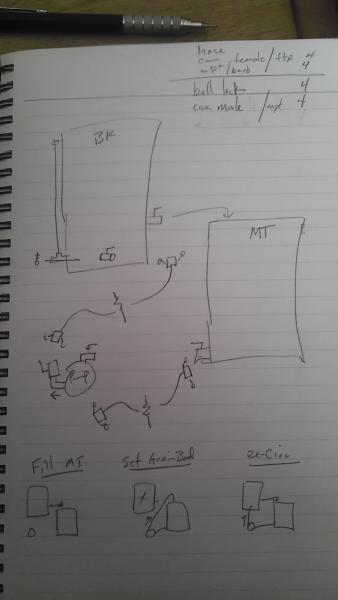

Minor update:

I brewed a 10 gallon batch of American Amber this weekend and the system performed beautifully. Mash in temperature for 15 gallons was reached in about 40 minutes, and the recirculation went very well. I had about a 1F differential between the tanks, and that is without any insulation on the MLT (it will be on there soon, though)

I also tried something new this week and really liked it. I conditioned the malt, which only took about 5-10 extra minutes before the brew day started. I used about 2% of the total grain weight as a guide for how much water to add.

My last batch I did not condition the malt and crushed at 0.037" and was 18% off of my theoretical maximum efficiency (actual 72%, theoretical 89%). This week I conditioned and crushed at 0.031". It left a flour with nearly entirely intact husks. I was 3% off of my theoretical maximum efficiency (actual 83%, theoretical 86%). I was also able to recirc at a decent clip without any sticking of the mash or rice hulls. I am not going to chase after efficiency, but it taught me about my system and a little more about brewing.

The theoretical maximum for a no sparge system is based on 100% conversion and is limited by lauter efficiency, which decreases as the wort moves to higher specific gravities. Assuming that lauter efficiency was at its theoretical maximum (a reasonable assumption for this system), for the last batch I achieved 81%conversion efficiency, and for the conditioned batch this week I was at 97% conversion efficiency. It is amazing to me what a single parameter like crush can do to overall brewhouse performance.

Joshua

I brewed a 10 gallon batch of American Amber this weekend and the system performed beautifully. Mash in temperature for 15 gallons was reached in about 40 minutes, and the recirculation went very well. I had about a 1F differential between the tanks, and that is without any insulation on the MLT (it will be on there soon, though)

I also tried something new this week and really liked it. I conditioned the malt, which only took about 5-10 extra minutes before the brew day started. I used about 2% of the total grain weight as a guide for how much water to add.

My last batch I did not condition the malt and crushed at 0.037" and was 18% off of my theoretical maximum efficiency (actual 72%, theoretical 89%). This week I conditioned and crushed at 0.031". It left a flour with nearly entirely intact husks. I was 3% off of my theoretical maximum efficiency (actual 83%, theoretical 86%). I was also able to recirc at a decent clip without any sticking of the mash or rice hulls. I am not going to chase after efficiency, but it taught me about my system and a little more about brewing.

The theoretical maximum for a no sparge system is based on 100% conversion and is limited by lauter efficiency, which decreases as the wort moves to higher specific gravities. Assuming that lauter efficiency was at its theoretical maximum (a reasonable assumption for this system), for the last batch I achieved 81%conversion efficiency, and for the conditioned batch this week I was at 97% conversion efficiency. It is amazing to me what a single parameter like crush can do to overall brewhouse performance.

Joshua