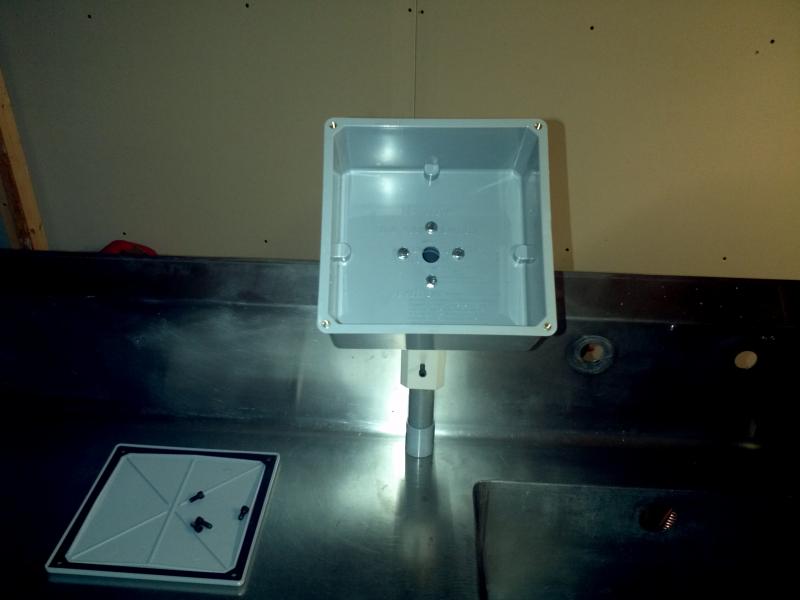

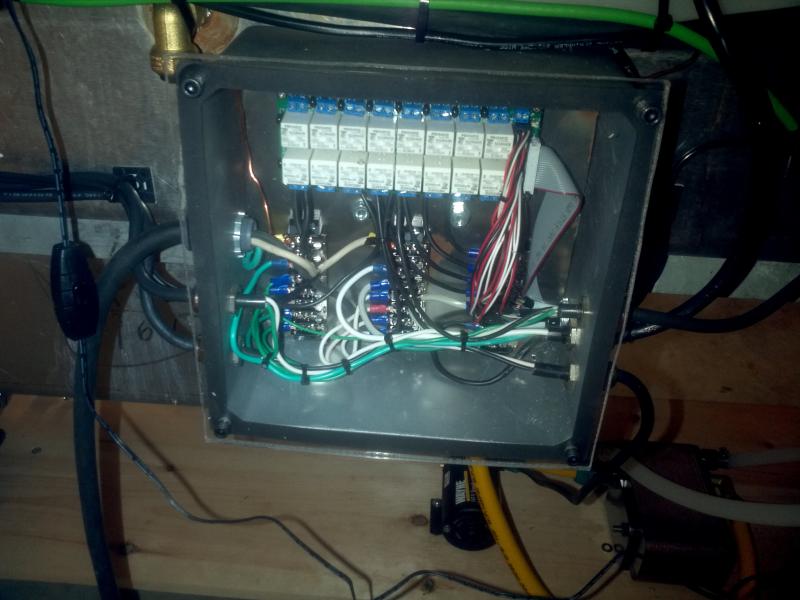

Here it is finally finished, build pics will follow shortly tho I must admit I was a little lazy documenting the build. It is powered by a Brewtroller 4 Pro board, and I used Blackheart's control panel as a model.

Enter your email address to join: