gib0r

Active Member

I recently treated myself to a Monster Mill MM2 for Giftmas, and opted out of the factory hopper (for the time being). In lieu of $30/$40 for this attachment, I figured I would mount the mill on the underside of the factory base and use a trashcan or similar with a hole cut in the bottom. My new hardware arrived today, and after playing with it for a few, realized I will be needing a way to direct my grain into the roller gap. This is my yet to be tested solution.

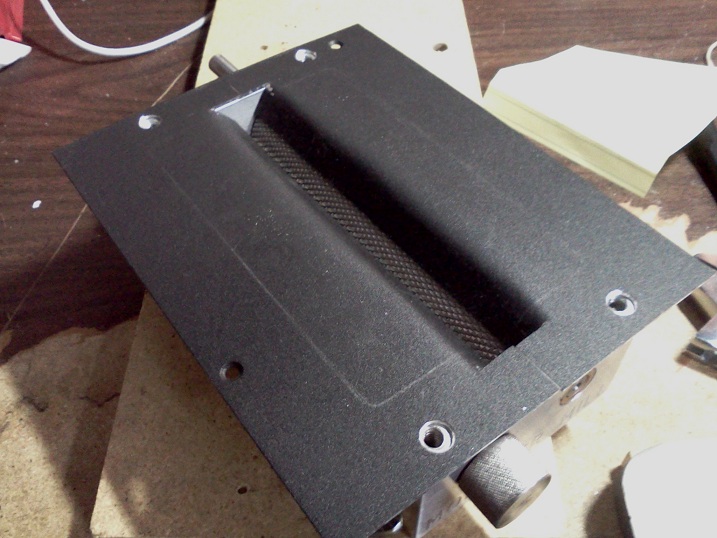

^The unboxing. The main assembly if massive.

^At any other time in my life I would have been more than happy to cut myself a base board for this, however living in an apartment has it's limitations...routing being one of them.

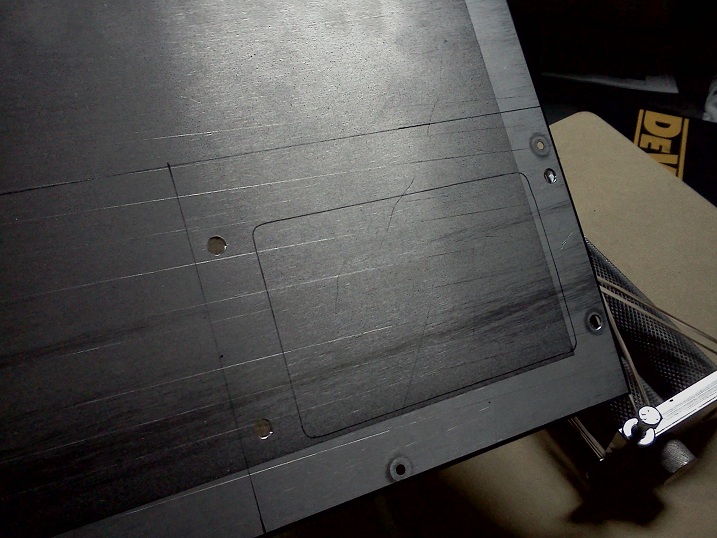

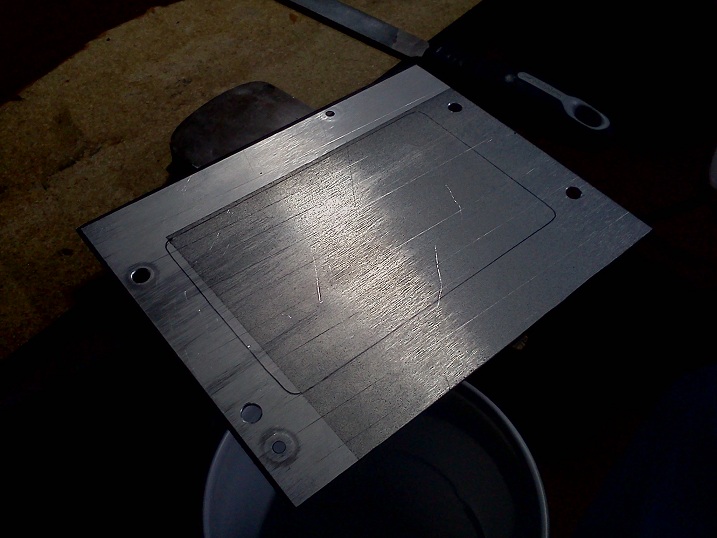

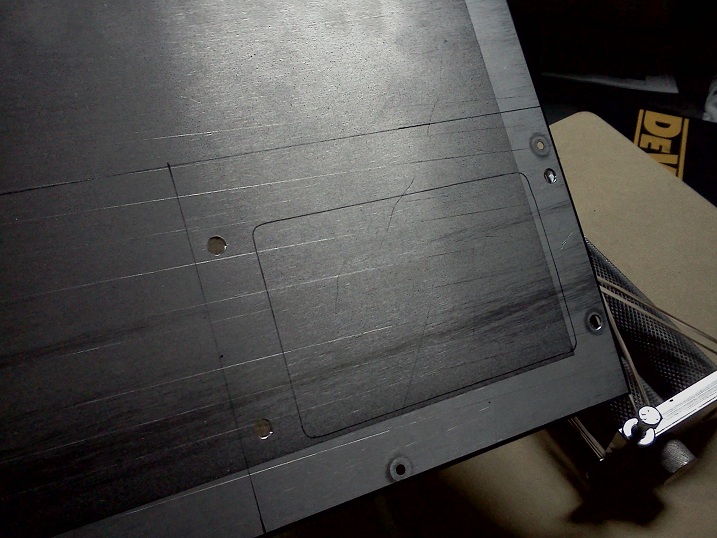

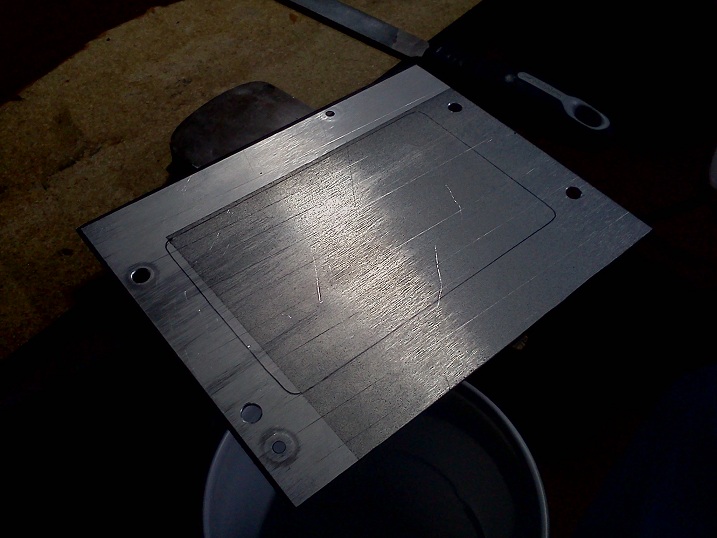

^Baseboard/mill underside.

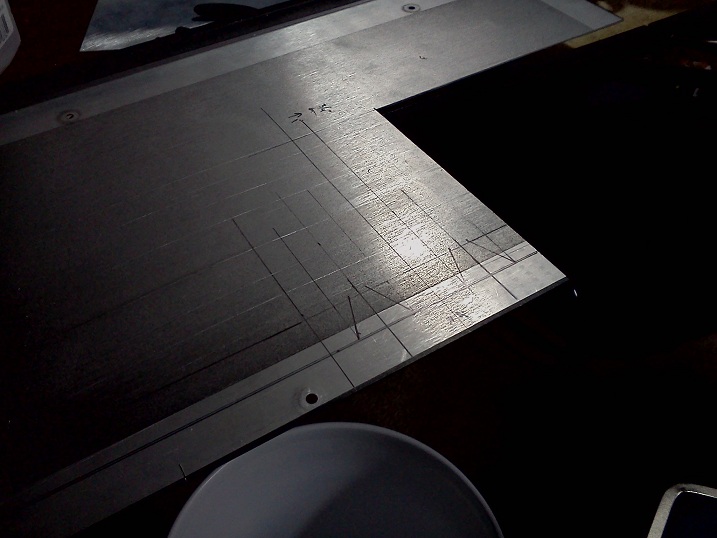

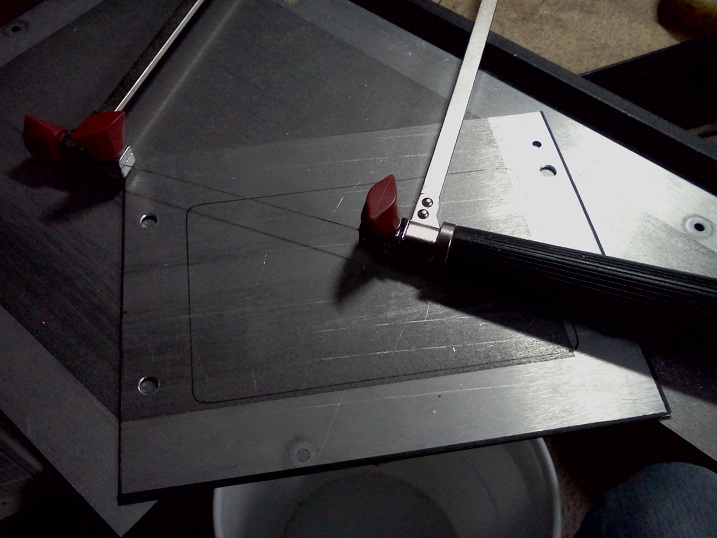

^Today we use salvaged aluminum panel from a server chassis. The base board was used as a template for screw hole placement and sheet sizing. Somewhat of a mistake as the baseboard screw holes themselves were not well placed in the board. Enlarging the holes took care of alignment issues.

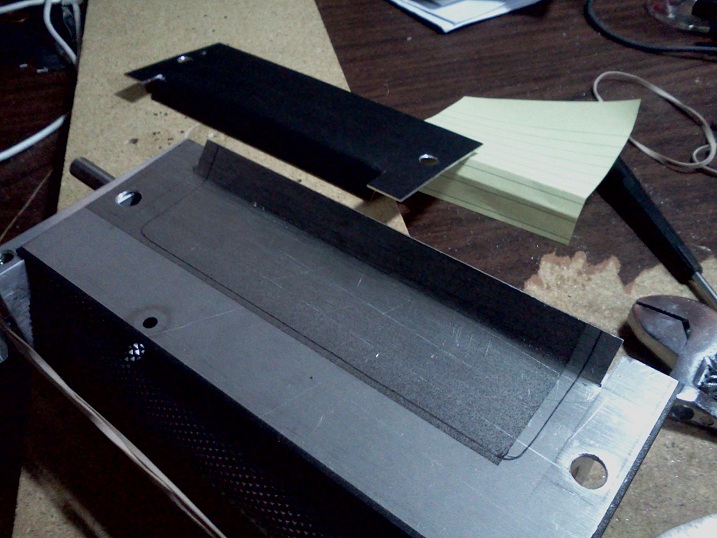

^Material removed using a large jeweler's saw.

^Edges filed and clean....

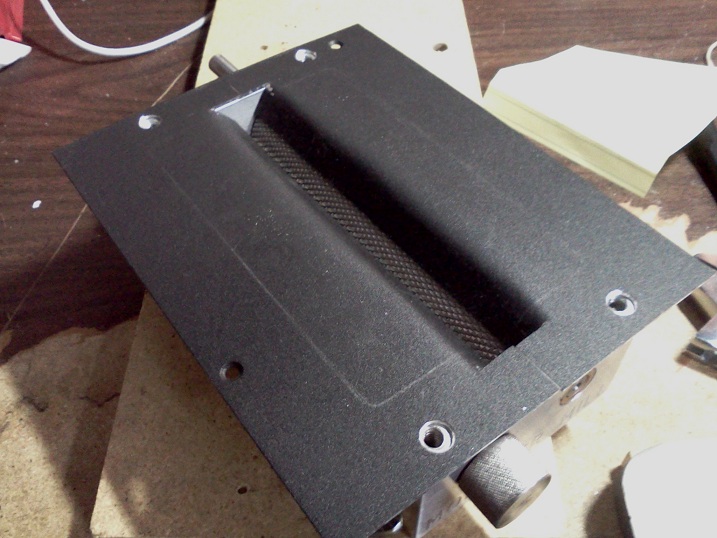

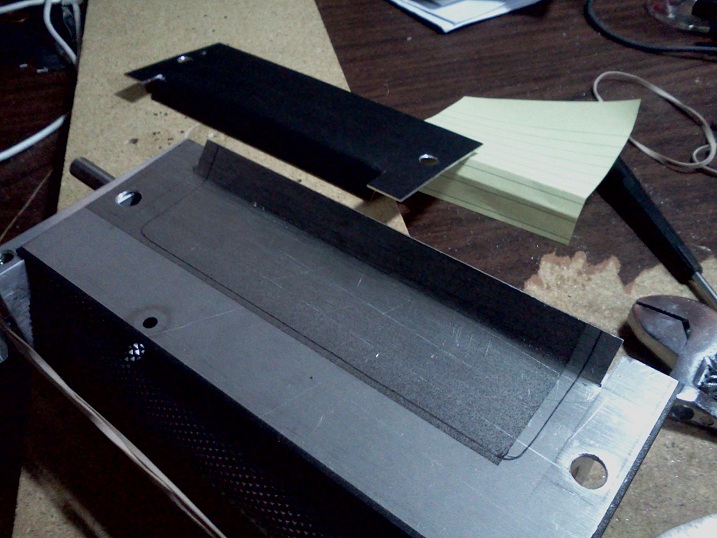

^Halved.

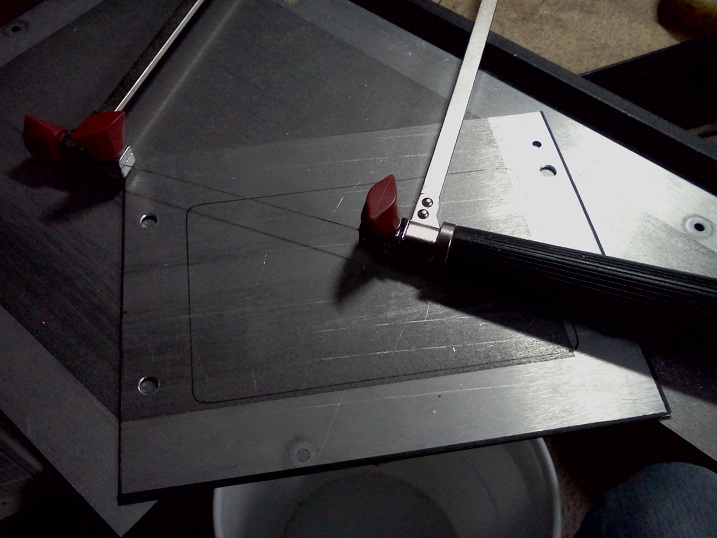

^It's hard to see, but I cut inward 1/2" on either side of each panel on what was measured to be the inside of the mill frame. I am using the vise as a straight edge to bend against.

^Bend angle was estimated and only needed a slight adjustment later on.

^The unboxing. The main assembly if massive.

^At any other time in my life I would have been more than happy to cut myself a base board for this, however living in an apartment has it's limitations...routing being one of them.

^Baseboard/mill underside.

^Today we use salvaged aluminum panel from a server chassis. The base board was used as a template for screw hole placement and sheet sizing. Somewhat of a mistake as the baseboard screw holes themselves were not well placed in the board. Enlarging the holes took care of alignment issues.

^Material removed using a large jeweler's saw.

^Edges filed and clean....

^Halved.

^It's hard to see, but I cut inward 1/2" on either side of each panel on what was measured to be the inside of the mill frame. I am using the vise as a straight edge to bend against.

^Bend angle was estimated and only needed a slight adjustment later on.