I built this in 2008, but I had pictures, so I figured I'd post them thinking I might give somebody ideas, hope, or motivation. A friend of mine (a brewer at one of the local brewpubs) thought he could use one after I was telling him about my plans, so we built two.

I live way up in the Northern Upper Peninsula of Michigan, and my ground water is usually pretty cold (around 43F in winter, 55F or so in summer), so this chiller is significantly shorter than most at 15 feet.

Measure and cut the 3/8" flex copper and rubber hose. Don't use the cheap plastic crap from Walmart. I got good quality rubber hose from SEARS.

Then we poured some soapy water into the hose so that the copper tubing would slide in easier. Save the jokes.

Here you go. Copper tube inside rubber hose.

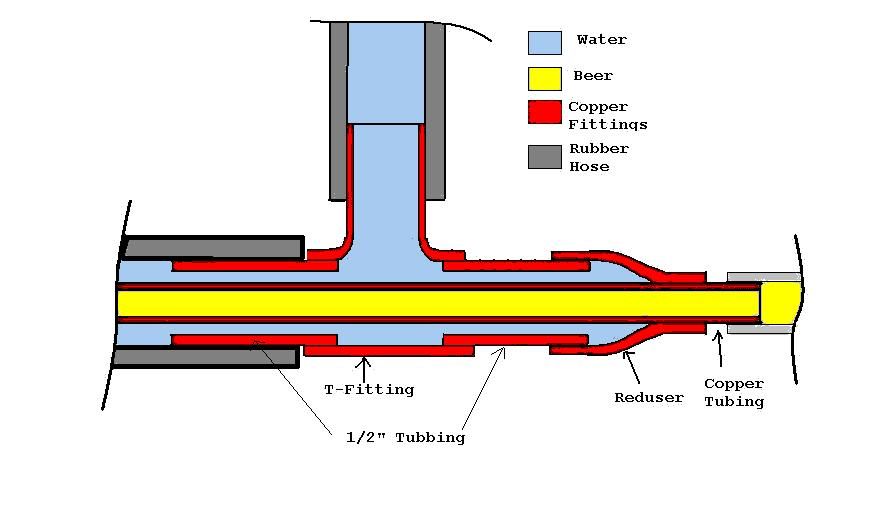

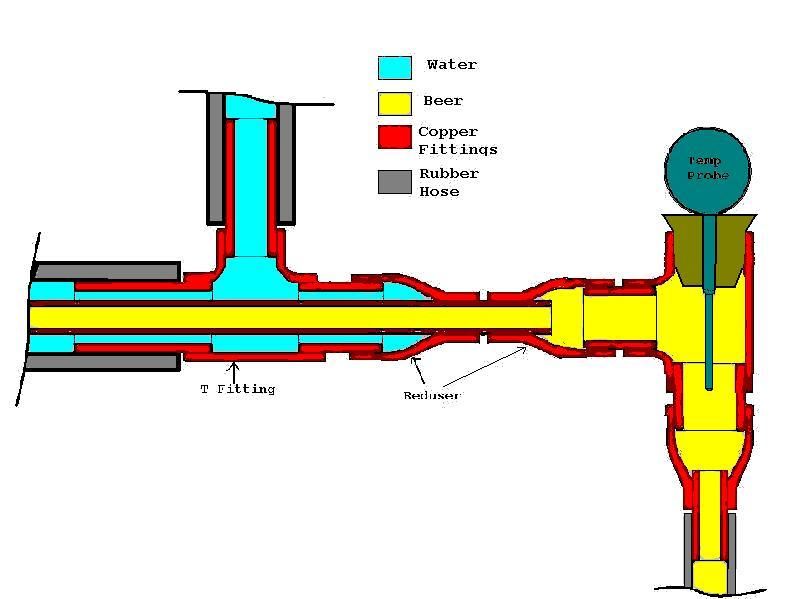

Now time to cut, clean and dry fit the copper fittings. Two 1/2" Tees, two 1/2 to 3/8 reducers, and some 1/2" pipe.

Solder the fittings together. I used lead free solder even though the beer won't be touching these joints just to be safe.

Test fit the pieces onto the hose and tubing. Good fit. Set aside for later.

Now time to coil the hose and tubing. First we poured some water into the copper tubing and folded the ends of both sides to seal it in. This will help keep the tubing from kinking while we wrap it into a coil.

[Continued on next post...]

I live way up in the Northern Upper Peninsula of Michigan, and my ground water is usually pretty cold (around 43F in winter, 55F or so in summer), so this chiller is significantly shorter than most at 15 feet.

Measure and cut the 3/8" flex copper and rubber hose. Don't use the cheap plastic crap from Walmart. I got good quality rubber hose from SEARS.

Then we poured some soapy water into the hose so that the copper tubing would slide in easier. Save the jokes.

Here you go. Copper tube inside rubber hose.

Now time to cut, clean and dry fit the copper fittings. Two 1/2" Tees, two 1/2 to 3/8 reducers, and some 1/2" pipe.

Solder the fittings together. I used lead free solder even though the beer won't be touching these joints just to be safe.

Test fit the pieces onto the hose and tubing. Good fit. Set aside for later.

Now time to coil the hose and tubing. First we poured some water into the copper tubing and folded the ends of both sides to seal it in. This will help keep the tubing from kinking while we wrap it into a coil.

[Continued on next post...]