You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

One barrel system

- Thread starter hermsfun

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

very cool. and i thought the same thing about the welding swivels. i think it might be more sturdy if you use a brace around the outside of the pot so the weight is distributed. but hell! you are the engineers im sure you thought of that

BBL_Brewer

Well-Known Member

You might want to check the volume on your BK before brew day. If jessup is right, it sounds like it's the same kettle I have and you won't be able to do a 1 bbl full volume boil. What I've been doing is splitting the wort between the BK and HLT so that I can do full boils and make two different beers.

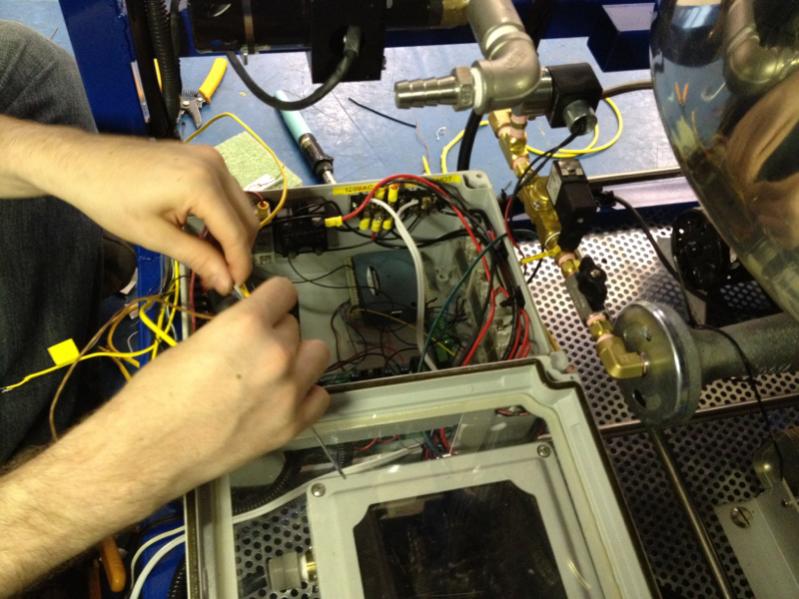

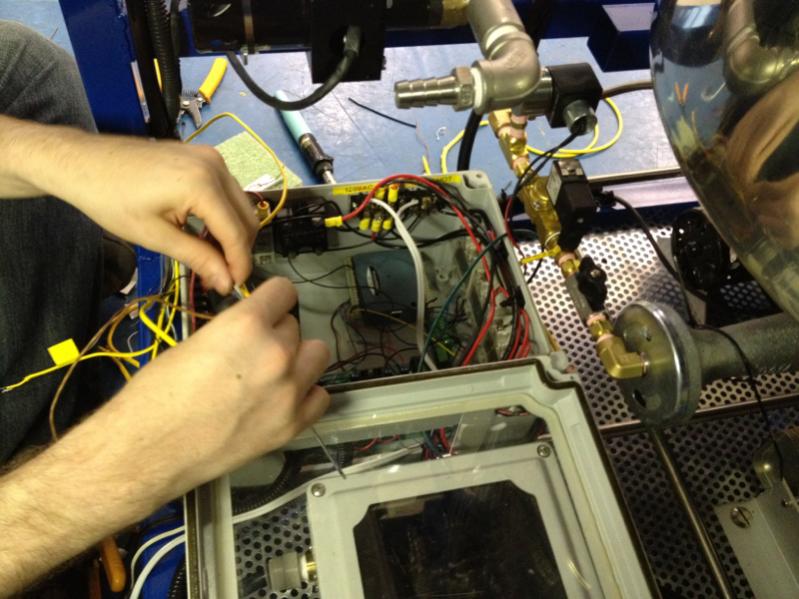

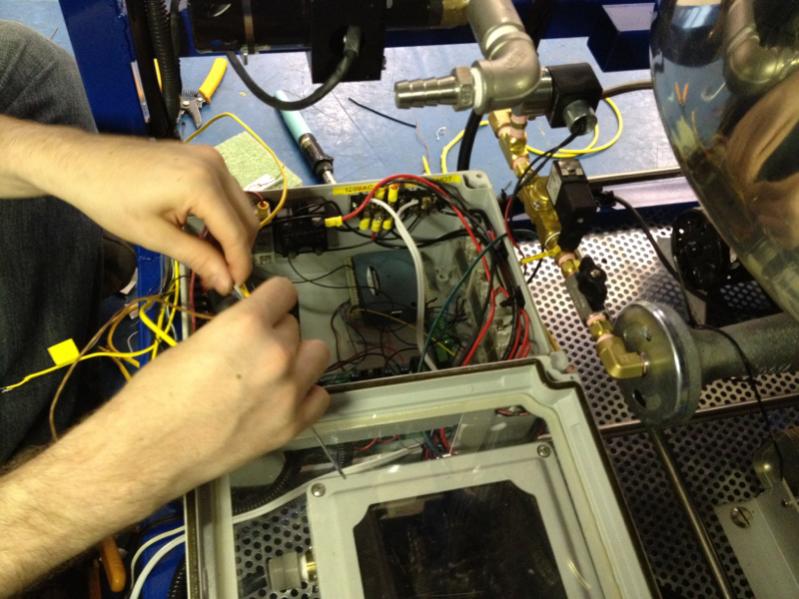

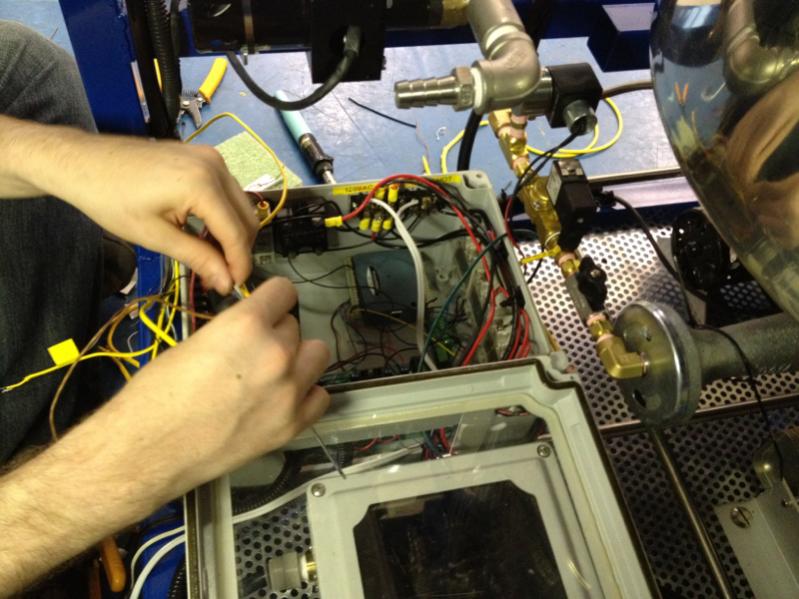

Yet another evening of testing. We made some improvements to the boil kettle heat shielding to protect the pump and heat exchanger directly below it. We also successfully controlled the pumps, cold water and wort valves all through the software. We added dough in water to the bk and started the burner. Everything worked great... Only one miss wired electric ball valve and an easy logic change on the software and we had everything running. We are planning on a northern English ale tomorrow evening!

bblack7489

Well-Known Member

That's a good looking system, guys.

I'm actually using LabVIEW to run my brewery as well. I have an embedded controller, a little LCD screen and a wi-fi router in the box so that it's stand-alone but I can also pull out a laptop and connect to it if I want. It's cool to see someone else out there using LV.

I have to say though that my mechanical engineering skills must have gone downhill since I've started working in the controls world. Your brew stand makes mine look like it was made by an elementary kid with a welder and a hot glue gun. Great stuff, and looking forward to seeing reports of it all in action.

I'm actually using LabVIEW to run my brewery as well. I have an embedded controller, a little LCD screen and a wi-fi router in the box so that it's stand-alone but I can also pull out a laptop and connect to it if I want. It's cool to see someone else out there using LV.

I have to say though that my mechanical engineering skills must have gone downhill since I've started working in the controls world. Your brew stand makes mine look like it was made by an elementary kid with a welder and a hot glue gun. Great stuff, and looking forward to seeing reports of it all in action.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Absolutely beautiful and compact 1 BBL build. Nice Job!

BBL_Brewer

Well-Known Member

So what did your BK volume end up being? If it was actually 45 gallons, I would like to buy one.

BBL_Brewer

Well-Known Member

We only did a 25 gallon batch this time but definitely only think it is 40 gallons like you said. The boil would be pretty exciting at 40 gallons too!

That figures. Thanks for the info. Nice build BTW, looks awesome.

julypena

Member

We only did a 25 gallon batch this time but definitely only think it is 40 gallons like you said. The boil would be pretty exciting at 40 gallons too!

I'm trying to DM you about this set up but it says your quota is full and you need to clear up space.

julypena said:I'm trying to DM you about this set up but it says your quota is full and you need to clear up space.

You could DM me, if you would like. I am part of this brew stand too with hermsfun and could let him know about the message.

OneHoppyGuy

Well-Known Member

this is a very nice build

Well Done!

Well Done!

julypena

Member

You could DM me, if you would like. I am part of this brew stand too with hermsfun and could let him know about the message.

Now I know. Anyways I was able to contact him now we're waiting for a reply

tszetela

Well-Known Member

The place is called nk designs. Just ask what colors they are running in the next couple weeks and they'll throw you in. Good luck!

This is great thing to know! Thanks!

Any chance you guys have a hydraulic schematic for your system? I'm planning my move from a gravity fed system to a pump system and am trying to layout all the switch logic. You have done an awesome job on this rig, thanks for posting!

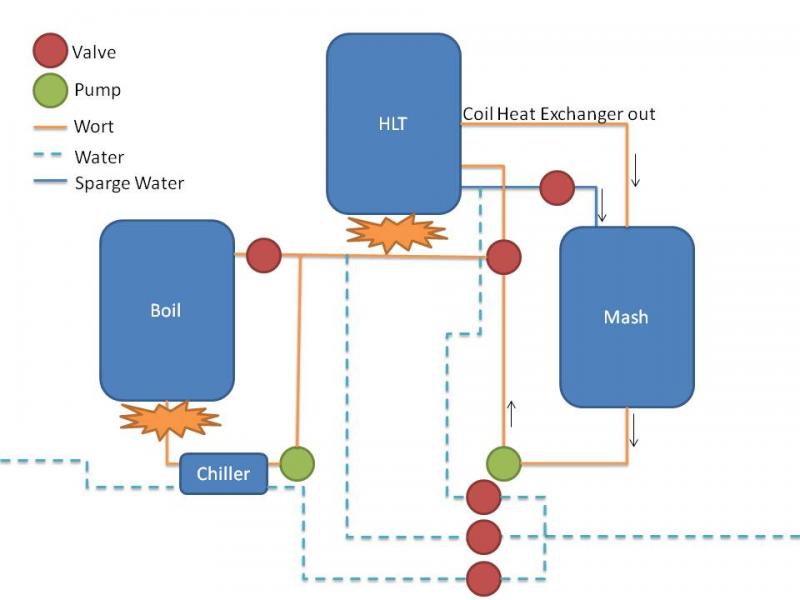

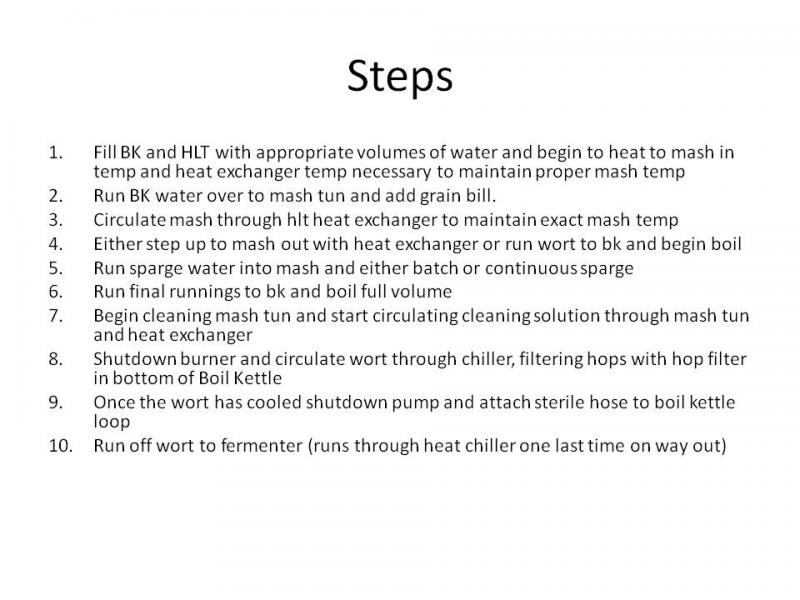

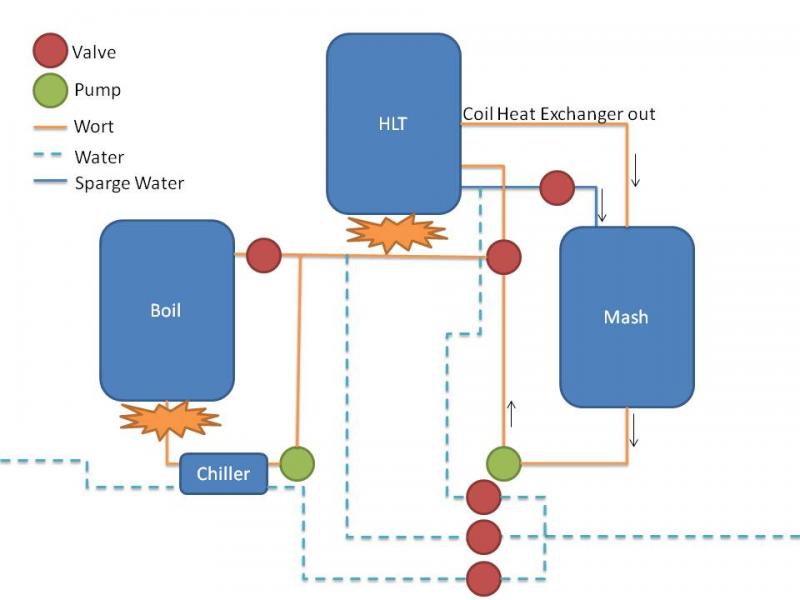

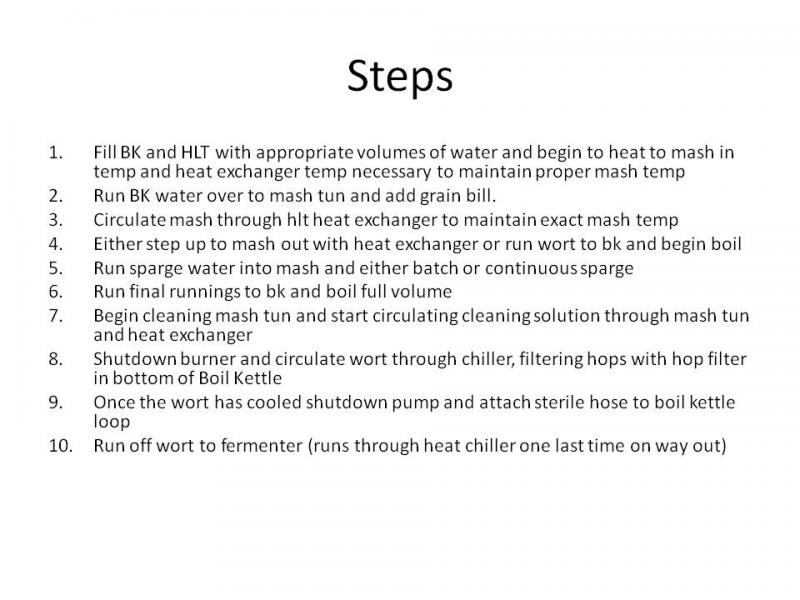

I made up a quick schematic for the plumbing. It doesn't include the fuel controls or the temperature sensing points. The HLT is still mounted above the mash tun to allow for gravity sparging and pumping to the boil kettle simultaneously.

Thanks! I appreciate the step by step instructions too, that makes it easy to follow. probably don't need the fuel controls as I will still be acting as the 'automation' on my system for now

One follow-up question on your schematic, I see you have a valve with 3 wort lines connected to it, did you find a multi-position valve that will open any two of those lines while closing off the third? So far all I've been using are simple ball valves while designing. A valve that can do that would really simplify my design.

Thanks again!

One follow-up question on your schematic, I see you have a valve with 3 wort lines connected to it, did you find a multi-position valve that will open any two of those lines while closing off the third? So far all I've been using are simple ball valves while designing. A valve that can do that would really simplify my design.

Thanks again!

There are three way valves out there... We are using an electronic ball valve but mcmaster and others do carry manual three ways. They basically switch between a common source. They cost a bit more but are cheaper than three two ways...

chairbornrangerx

Well-Known Member

ah I remember playing with labview back in college! Fun software

There are three way valves out there... We are using an electronic ball valve but mcmaster and others do carry manual three ways. They basically switch between a common source. They cost a bit more but are cheaper than three two ways...

You can also get automated 3-ways. I built a couple of them for my home heating system. They make 4-way valves too.

CoalCracker

Well-Known Member

Great looking system. Where did you get the electronic ball valves? Also, are they 12v or 110v?

Sounds like your making headway. I would recommend that you go directly to the fermenator and not back into the BK. In a few hours you can drain off the heavy solids that settle out very easy. Less cool wart exposed to the atmosphere the better. Adjust your flow and get your desired temp first time through.

Similar threads

- Replies

- 0

- Views

- 204

- Replies

- 1

- Views

- 623

- Replies

- 1

- Views

- 837

- Replies

- 0

- Views

- 223