MaxOut

Well-Known Member

I frequently search the web for items that can be used to improve my current brew rig and recently have been looking for a larger kettle to boil in. I have plenty of mash lauter tun capacity but need more boil capacity. I frequently brew the same recipe over and over to keep my pipeline flowing with a house flavor 444 Triple Lager. I have this recipe down and would like to brew it less often and in larger quantities so I have time to try other small recipes. Well in my searching I found an add on Craigslist for a 40 gallon jacketed steam kettle on wheels that ran on propane advertised as the ultimate crab or lobster cooker for the man cave. I tried to contact the seller for over a week and the add was nearly a 5 weeks old I figured it was sold and the seller was not interested in returning calls. Well out of the blue my phone rang and it was the seller. I went the next morning to meet him and purchased the kettle. When I arrived to pick up the kettle it was much larger than I had imagined and was quite a bear for three of us to lift up into my box truck. Long story short I got it home, cleaned it up and connected it to my propane at my brewery and fired it up. At this point I went on line to look for a manual or schematics so I could figure out how to interface with the existing controls. When I pulled up the model number things started to make more sense

.GL60N

60 Gallon Not the 40 Gallon Advertised. Much bigger than I originally intended to purchase but now its got me thinking

Hmmm. Should I sell this and continue to look for another boil kettle or entertain the idea of a single vessel 1BBL all grain all in one system from grain to glass?

Ive searched the forums and see some threads on using jacketed steam kettles to brew in but have not found a complete thread with details on how this is done or can be done. I have a few ideas but wanted to run it through HBT to get some opinions

Please go easy on me this is just a theory at this point and looking for consrtuctive criticism. Thanks In advance

This is what Im thinking-

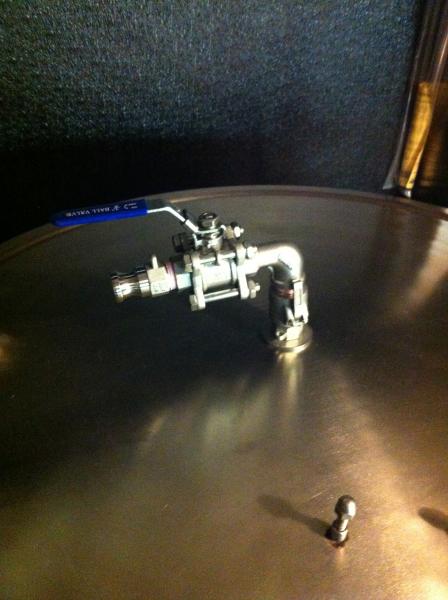

Make a large perforated stainless steel basket that fits inside kettle to hold grain (kinda like BIAB). Use my instant hot water heater to supply strike water and sparge water (goes to 180 degrees). Integrate kettle gas valve to existing BCS, add thermister to long custom rod that can be positioned in the mash where desired through hole in lid and regulate mash temp with kettle. Mount a wort pump and a plate chiller to the kettle. Install inlet through lid for recirculation return and weld tri clamp adapter to existing dump valve. Rig chain fall above kettle to lift basket after mash and elevate above wort during sparge. After sparge remove grain basket and bring to boil adding hops in a large hop spider. Remove hop spider after boil and recirculate through plate chiller to cool. Pitch yeast close lid and add airlock. Add valves to front and rear in existing ports to allow water through jacket to help cool/heat wort as needed to maintain fermentation temps. Water in jacket will be in a closed loop to avoid contamination and deterioration of jacket. I will add a high tem gasket to the lid of the kettle and a latch to lock it down during fermentation. Dump yeast and trub with dump valve and siphon beer into kegs.

Included a couple pictures of the steam kettle for visualization. Im going to run some water tests with the kettle to determine some base line capabilities. At this point Im not even sure this thing will boil water? OK fire away

Ive searched the forums and see some threads on using jacketed steam kettles to brew in but have not found a complete thread with details on how this is done or can be done. I have a few ideas but wanted to run it through HBT to get some opinions

Please go easy on me this is just a theory at this point and looking for consrtuctive criticism. Thanks In advance

This is what Im thinking-

Make a large perforated stainless steel basket that fits inside kettle to hold grain (kinda like BIAB). Use my instant hot water heater to supply strike water and sparge water (goes to 180 degrees). Integrate kettle gas valve to existing BCS, add thermister to long custom rod that can be positioned in the mash where desired through hole in lid and regulate mash temp with kettle. Mount a wort pump and a plate chiller to the kettle. Install inlet through lid for recirculation return and weld tri clamp adapter to existing dump valve. Rig chain fall above kettle to lift basket after mash and elevate above wort during sparge. After sparge remove grain basket and bring to boil adding hops in a large hop spider. Remove hop spider after boil and recirculate through plate chiller to cool. Pitch yeast close lid and add airlock. Add valves to front and rear in existing ports to allow water through jacket to help cool/heat wort as needed to maintain fermentation temps. Water in jacket will be in a closed loop to avoid contamination and deterioration of jacket. I will add a high tem gasket to the lid of the kettle and a latch to lock it down during fermentation. Dump yeast and trub with dump valve and siphon beer into kegs.

Included a couple pictures of the steam kettle for visualization. Im going to run some water tests with the kettle to determine some base line capabilities. At this point Im not even sure this thing will boil water? OK fire away