stamandster

Well-Known Member

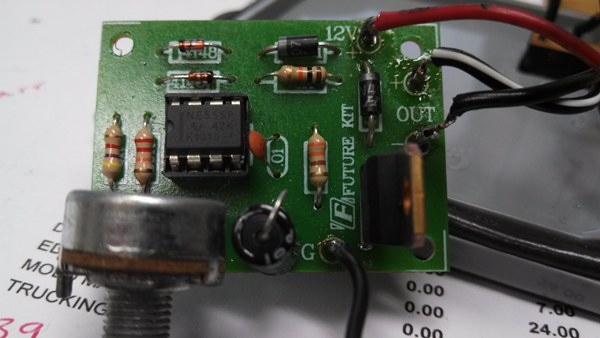

Just in case someone didn't want to build one I think that this would be useful

http://dx.com/p/1-ch-96w-manual-led-strip-dimmer-white-dc-12v-163667?item=25

You have to add a SSR anyways sooo... seems like it'd work. 12v input though.

http://dx.com/p/1-ch-96w-manual-led-strip-dimmer-white-dc-12v-163667?item=25

You have to add a SSR anyways sooo... seems like it'd work. 12v input though.