slakwhere

Well-Known Member

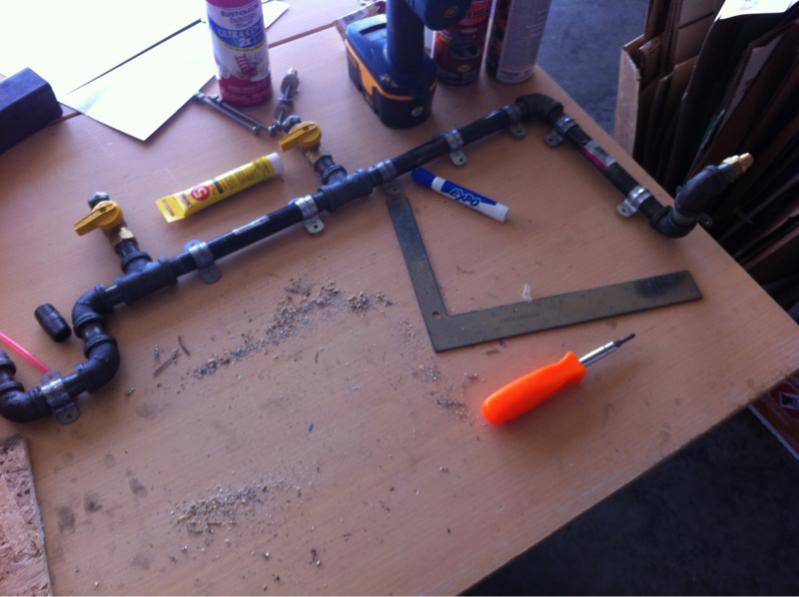

for the rest of the build, hit the areas to be welded with the grinder BEFORE you weld them. your pre-weld pictures need to look like your post-grind pictures. i promise it's way easier to weld clean materials without rust/oil/etc.