Craig5_12

Well-Known Member

I'm submitting my dillema to the powers of HBT: What do you guys think?

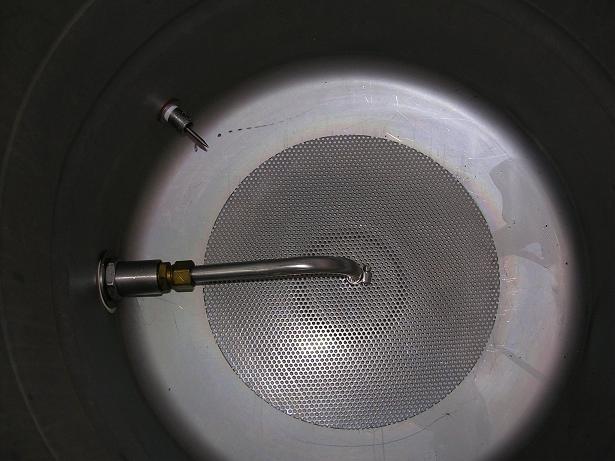

I need to upgrade my false bottoms, the SS / AL screen isn't cutting it anymore. I'm wondering if I should buy these pre-made false bottoms (below) or just build my own? (I need one for Sanke MLT and one for Sanke Kettle)

My dillema:

The pre-made are nicely shapped and cut already but they're only 11.5" inches wide (Sanke's are 15.5")

The price for the material is about the same either way, but with homemade I can go the full 15.5" of the keg.

Because the price is the same, I'm thinking about taking the easy way out and buying the pre-made. My time, effort and gas money for building my own will outweigh the price of the pre-made BUT I will get the full width of my keg...so is that worth it?

EDIT: I can't tell if the pic is working or not, so here is the address: http://www.northernbrewer.com/pics/fullsize/abt-false-bottom.jpg

I need to upgrade my false bottoms, the SS / AL screen isn't cutting it anymore. I'm wondering if I should buy these pre-made false bottoms (below) or just build my own? (I need one for Sanke MLT and one for Sanke Kettle)

My dillema:

The pre-made are nicely shapped and cut already but they're only 11.5" inches wide (Sanke's are 15.5")

The price for the material is about the same either way, but with homemade I can go the full 15.5" of the keg.

Because the price is the same, I'm thinking about taking the easy way out and buying the pre-made. My time, effort and gas money for building my own will outweigh the price of the pre-made BUT I will get the full width of my keg...so is that worth it?

EDIT: I can't tell if the pic is working or not, so here is the address: http://www.northernbrewer.com/pics/fullsize/abt-false-bottom.jpg