So I have just set up my first kegerator! I was surprised at how easy it was, and I have checked my system many times. It is working adequately. I say adequately because I believe there is room for improvement.

My current settings are 5 psi and I believe what my two problems in my system is one my temperature in my fridge could be a little coolder, however it is at minimum 40 and sometimes colder, I have not gotten a true temperature due to faulty temperature gauges and thermometers, however I left 2 glasses of water overnight and a thin layer of ice was on the top of the cups, leading me to believe it is probably adequately cold although can improve a little. My second problem I believe is with resistance, my faucet/shank and keg coupler that attaches to the keg are at about the same level maybe an inch difference. I have a standard 5 ft of line.

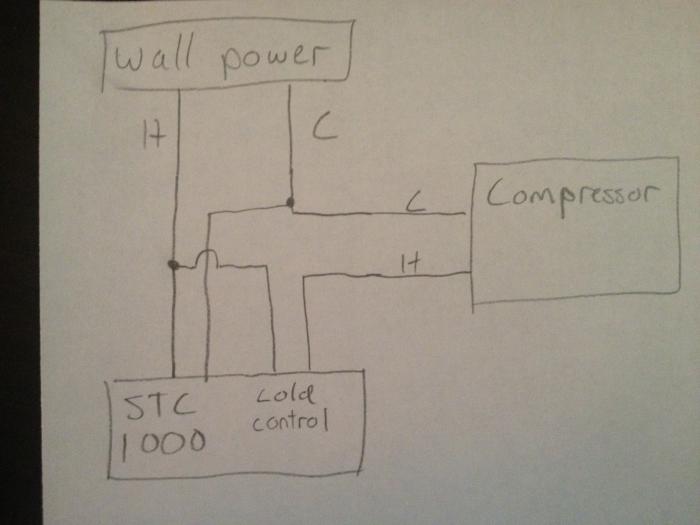

I am a noob, but I kind of think I need a little more line to increase my resistance, I would like to have my psi a little higher to get a better flow, I would also like my beer to be a little colder and have heard nothing good about drilling a small hole or decent size hole form freezer to fridge.

Any more information needed to help let me know, can also upload pictures of my set up if it would help.

Thanks in advance and sorry so long,

boykin

My current settings are 5 psi and I believe what my two problems in my system is one my temperature in my fridge could be a little coolder, however it is at minimum 40 and sometimes colder, I have not gotten a true temperature due to faulty temperature gauges and thermometers, however I left 2 glasses of water overnight and a thin layer of ice was on the top of the cups, leading me to believe it is probably adequately cold although can improve a little. My second problem I believe is with resistance, my faucet/shank and keg coupler that attaches to the keg are at about the same level maybe an inch difference. I have a standard 5 ft of line.

I am a noob, but I kind of think I need a little more line to increase my resistance, I would like to have my psi a little higher to get a better flow, I would also like my beer to be a little colder and have heard nothing good about drilling a small hole or decent size hole form freezer to fridge.

Any more information needed to help let me know, can also upload pictures of my set up if it would help.

Thanks in advance and sorry so long,

boykin