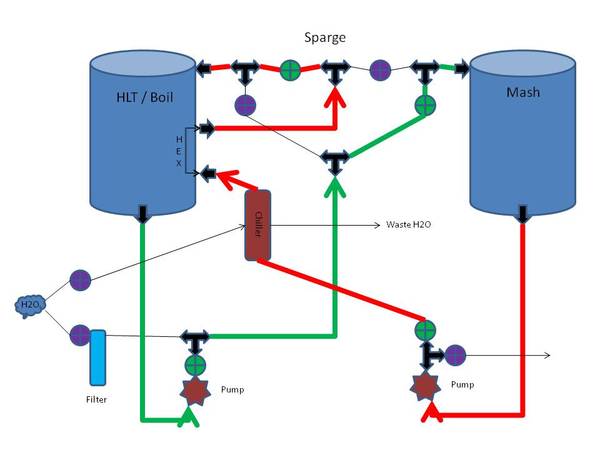

This will be the start of my build thread to my automated system. I have finally determined my valve setup, after several different attempts (see photo). I have purchased a BT3.3 from a fellow brewer. I will likely upgrade to the DX1 board, however I wanted to use a legacy system to ensure it had all features in place already.

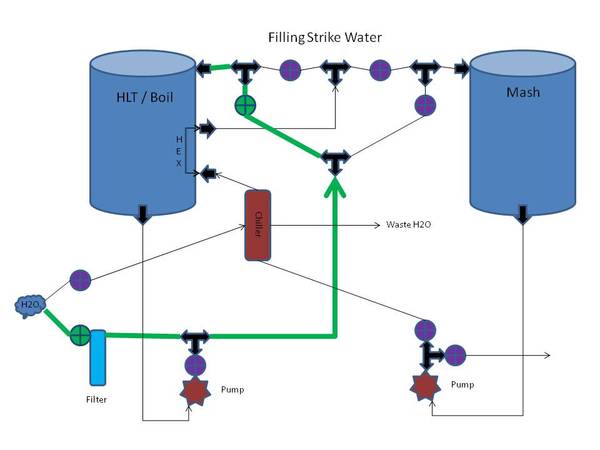

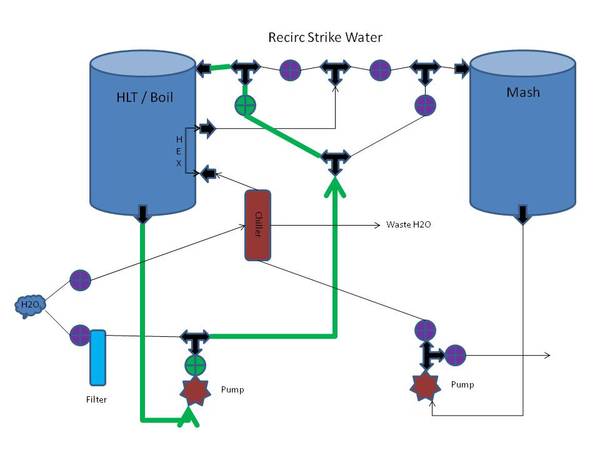

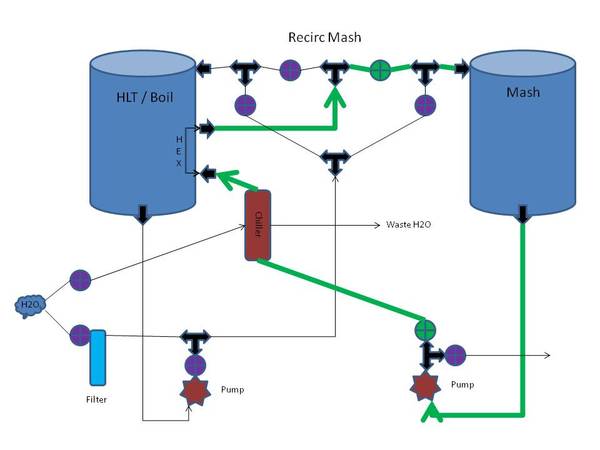

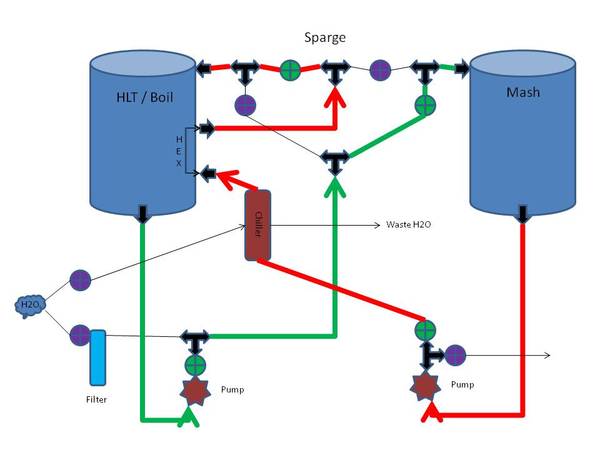

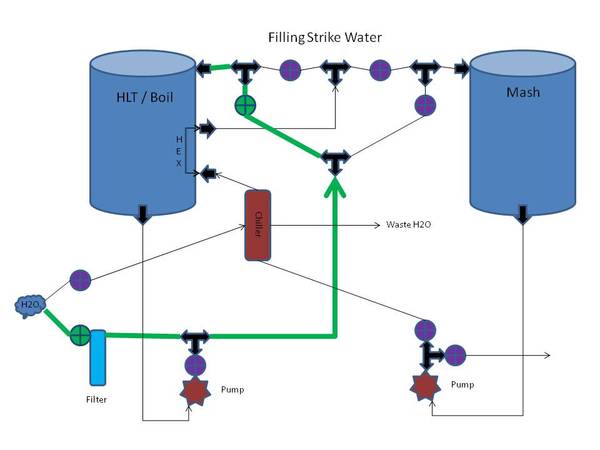

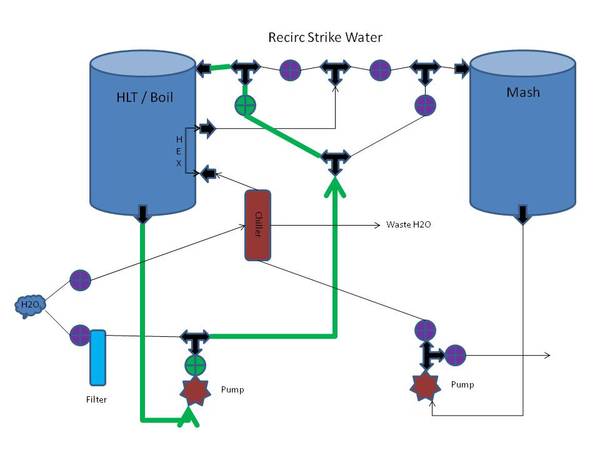

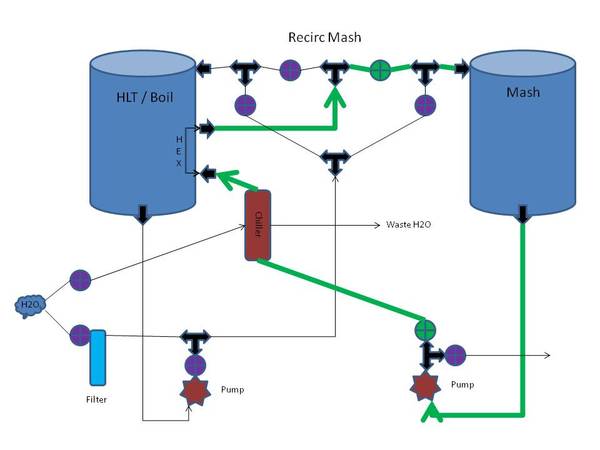

The system will run off 30A GFCI, and will be based off the brutus 20 two vessel setup. I chose this design over my current HERMS three vessel as I'm looking for something that would take up less space and provide the ability to do 10-12g batches of smaller beers and 7g batch of a big beer.

The system will run on a total of 9 valves (1 not shown is H2O input to chiller). It will also be using 2x chuggerpumps (Upgrading from March). There will be no more changing tubing throughout the brew, however for cost and ease I will be using silicone at first. (Hard plumbing in future once everything running smooth). The other advantage to using Brewtroller is volume sensors, which I will have one on the HLT/BK vessel.

Let me know what you guys think guys, I'll be updating as things continue.

UPDATE:

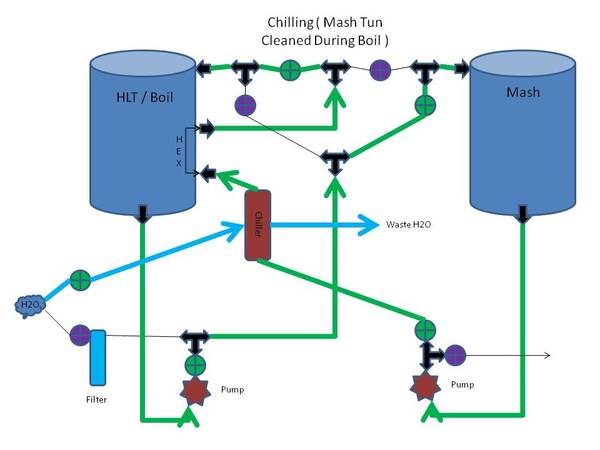

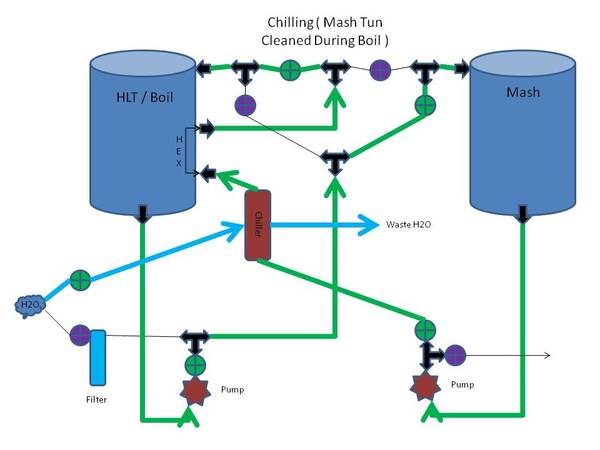

My only issue is with chilling, however now that I have designed the diagram have found my solution. I can move the chiller to be inline with the BK/HLT pump. This way I will not need the second vessel at all after boil.

The system will run off 30A GFCI, and will be based off the brutus 20 two vessel setup. I chose this design over my current HERMS three vessel as I'm looking for something that would take up less space and provide the ability to do 10-12g batches of smaller beers and 7g batch of a big beer.

The system will run on a total of 9 valves (1 not shown is H2O input to chiller). It will also be using 2x chuggerpumps (Upgrading from March). There will be no more changing tubing throughout the brew, however for cost and ease I will be using silicone at first. (Hard plumbing in future once everything running smooth). The other advantage to using Brewtroller is volume sensors, which I will have one on the HLT/BK vessel.

Let me know what you guys think guys, I'll be updating as things continue.

UPDATE:

My only issue is with chilling, however now that I have designed the diagram have found my solution. I can move the chiller to be inline with the BK/HLT pump. This way I will not need the second vessel at all after boil.