Help!

Ok so I just tore apart the kids swingset because it was made out of wood that has started to rot away, however there is still quite enough there that got me thinking about building a modified, Son-Of-A-Fermentation chamber.

I use 2x Mr. Beer kegs, I was planning on building it with one on top of the other with separate shelves, and a small fan that stays on moving air between the two to keep it the same. The cooling chamber will remain the same on the back, pulling the air flow out of the top of the main chamber, making the air flow to the bottom where the ice it, before re-entering the main chamber through the top by a temperature controlled fan.

I have everything to make this happen except for the temperature switch. Is the STC-1000 the cheapest thing out there? I just need something that I don't care if it's digital or not to close a relay to turn the fan off if it ever gets higher than 62-65.

Also, will 1 fan circulating the air between the two halves be enough to keep it the same temperature and not make one hotter than the other?

Thanks

Ok so I just tore apart the kids swingset because it was made out of wood that has started to rot away, however there is still quite enough there that got me thinking about building a modified, Son-Of-A-Fermentation chamber.

I use 2x Mr. Beer kegs, I was planning on building it with one on top of the other with separate shelves, and a small fan that stays on moving air between the two to keep it the same. The cooling chamber will remain the same on the back, pulling the air flow out of the top of the main chamber, making the air flow to the bottom where the ice it, before re-entering the main chamber through the top by a temperature controlled fan.

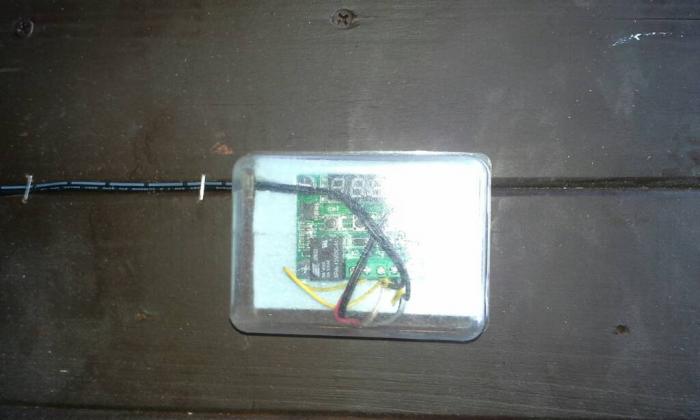

I have everything to make this happen except for the temperature switch. Is the STC-1000 the cheapest thing out there? I just need something that I don't care if it's digital or not to close a relay to turn the fan off if it ever gets higher than 62-65.

Also, will 1 fan circulating the air between the two halves be enough to keep it the same temperature and not make one hotter than the other?

Thanks