goatchze

Well-Known Member

BTW, thanks for the debate guys. You're givine me something to do while bored in this hotel in Holland!

No need to get touchy. If you present your work as evidence, expect comments.

On my calculator I would go from 58.6% up to 72.4% assuming the same boiloff rate and time. It is a big jump, but I also would go from a 1.113 OG down to 1.069.

For the calculator that I use, I assume a 100% conversion. This is perhaps not realistic, but is good enough for playing with theory and designing a rig.

What if you doubled your water volume at 30 pounds of malt Jkarp? In your graph, would that change the eff.? Just curious.

I mean at 30 pounds of malt in a 5.5 gallon batch, youd be absorbing A LOT of your total mash wort, right? What if you doubled that water volume? What number would you have then?

Also, these graphs are cool, what is the "assumed" conversion eff. in these graphs?

Ok, your graph matches my initial statement several pages back. Thanks.

30 pounds, in a 10 gallon batch, at 72% is fine for me as that is an OG of about 1.084. I am typically in the 1.040 - 1.070 range with my beers.

I can handle 72%

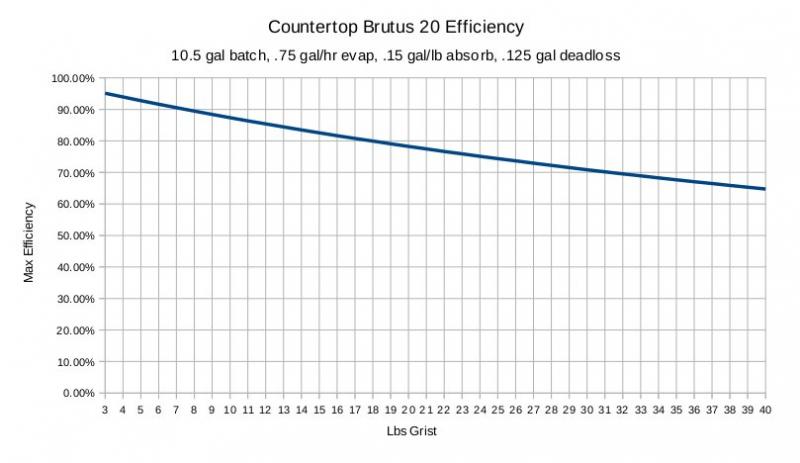

Of course, that's a theoretical max and actual results will be a few points below that. Getting the absorption rate and deadloss down makes a surprising difference in no-sparge efficiency. I recall you were doing some malt conditioning and that should really pay off for you there. With a 30 lb grist, just going from 0.15 gal/lb to 0.1 gal/lb gets you another 7-8%

I've got a little excel sheet I use for brewday volume calculations that makes grinding all these numbers easy if you're interested.

goatchze - the math was all laid out. What exactly aren't you understanding?

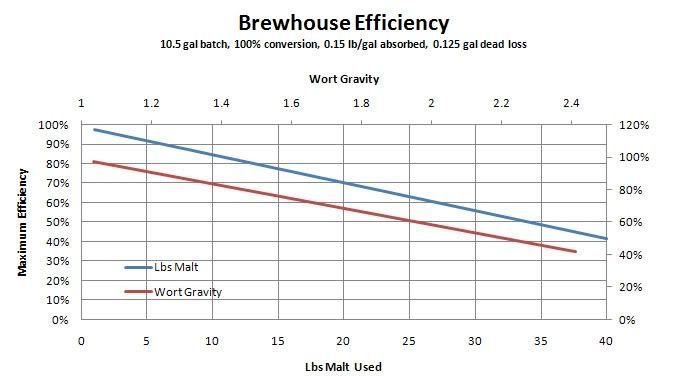

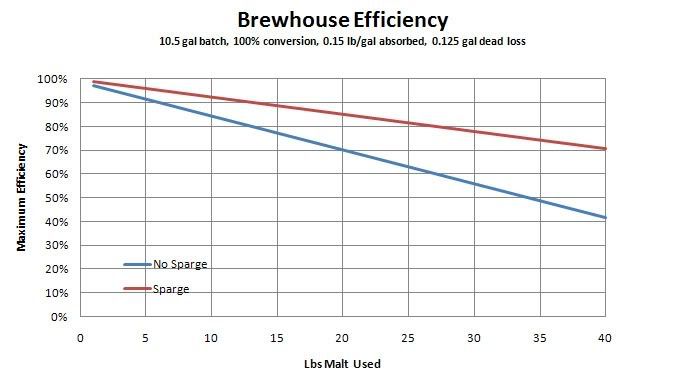

Boil-off must be compensated for on the front end in no-sparge. If you want 5 gallons of beer and you boil off 1 gallon, you'd better have 6 gallons pre-boil to avoid disappointment. When the mash is more dilute, the points per gallon is lower. Consequently, the actual points lost to absorption goes down. As absorption and deadloss are the ONLY sources of lost efficiency in no-sparge, the overall mash efficiency goes UP as pre-boil volume increases.

Right, but you started this thread with a Brutus 20 question. Brutus 20 is no-sparge. Batch sparging and fly sparging have different efficiency calculations entirely.

Brutus 20 is elegant in its simplicity. You've got X gallons in a closed loop, recirculating. Eventually, the wort gravity is uniform throughout the system. Assuming 100% conversion, at this point you have absolute perfect, 100% efficiency. No exceptions. No losses have occurred.

It's easy to calculate or even take an actual reading of the wort gravity at this point. Now run the wort off to the kettle. The difference in the volumes of what you started with and what's in the kettle now is your volume loss. You know the gravity, you know the volume. That's all you need to now determine the points lost and your mash efficiency.

GRAIN x PTS / [(GRAVITY-1)*VOLUME)] = EFF

where:

GRAIN = lbs of grain

PTS = gravity points per lb in one gallon

GRAVITy=specific gravity of wort, pre or post boil doesn't matter

VOLUME=volume of wort, pre or post boil doesn't matter as long as you're consistent

It would be easier to say that 1 lb of 2-row should yield 0.31 lbs of sugar.

Now, to help you understand why boil time / evaporation is important, let's do the same example, adjusted for a 90 minute boil.

(Recall our original conditions: Say we want 5 gallons of 1.073 finished wort and want to do a 90 min boil. We know our system will boil off 0.75 gal/hr. Let's also assume our grist absorbs 0.125 gal/lb and our MLT has 0.25 gal of deadloss.)

Full Brutus 20 system volume will be 5 gal + (1.5 hr x .75 gal) + (12 lbs x .125 gal/lb) + .25 gal = 7.875 gal

444 / 7.875 = 56.4 points pre-boil

Now, back to your formula:

GRAIN = 12

PTS = 37

GRAVITY = 1.0564 (pre-boil; you said it doesn't matter)

VOLUME = 6.125 gal (again, pre-boil, per your requirement to be consistent)

"GRAVITY-1" = 56.4

56.4 * 6.125 = 345.45

12 * 37 = 444

345.45 / 444 = 77.8% efficiency.

So, simply by going from a 60 minute to 90 minute boil, NO other changes, our theoretical max Brutus 20 efficiency went up by a little over 1%.

People can get confused when you say that a longer boil will increase efficiency because they think "I'm increasing the gravity of my wort in the boil, thus increasing efficiency". This, of course, is not the case.

As for you last post, I'm not saying sugar as in "sucrose" or "table sugar". If we assume that wort is a mixture of only two things, water and sugar (of whatever kind), then every point of gravity above 1.0 is due to a sugar (of whatever kind).

0.31 lbs i the amount of sugar (of whatever kind) which should be produced from 1 lb of malt.

So, now that we're off of this tangent, let's go back to my original question. Your above comment that the gravity of the wort "lost" affects the overall efficiency (which I agree with completely) is of course the justification for using a sparge. The Brutus doesn't use a sparge, so the above logic means the efficiency must be lower. This means you need more grain to get the same amount of beer.

The Brutus also requires two pumps, so a higher cost to build (for me the pump was one of the largest expenses on my build).

So what I'm still not understanding, or seen shown, is what the advantage of the Brutus set up is? I'm not trying to knock it; it obviously works and is quite popular. However, the only advantage I see is the elmination of a small water bottle if not using tap water. If using tap water, I see no advantage at all?

Meanwhile there are multiple negatives, mainly a loss in efficiency and need for an additional pump?

So, again, what am I missing? Do the pros really outweight the cons, or are so many people building this system because it's been done before and is easy to duplicate?

This is 100% patently false, as I just proved! In a Brutus 20 system, increased boil time or higher evaporation rates MUST be compensated for by adding more water up-front. This drives down the pre-boil gravity which means MORE points get in the pot. MORE points in the pot = higher efficiency.

Sorry, but you proved no such thing. What you proved was that increased water, compensated for by a longer boil, increases efficiency. A longer boil by itself does not help. Goatchze's point, as I understand it, was that when people simply hear that a longer boil increases efficiency they can be misled because they are missing half the picture.

Enter your email address to join: