GrantH

Well-Known Member

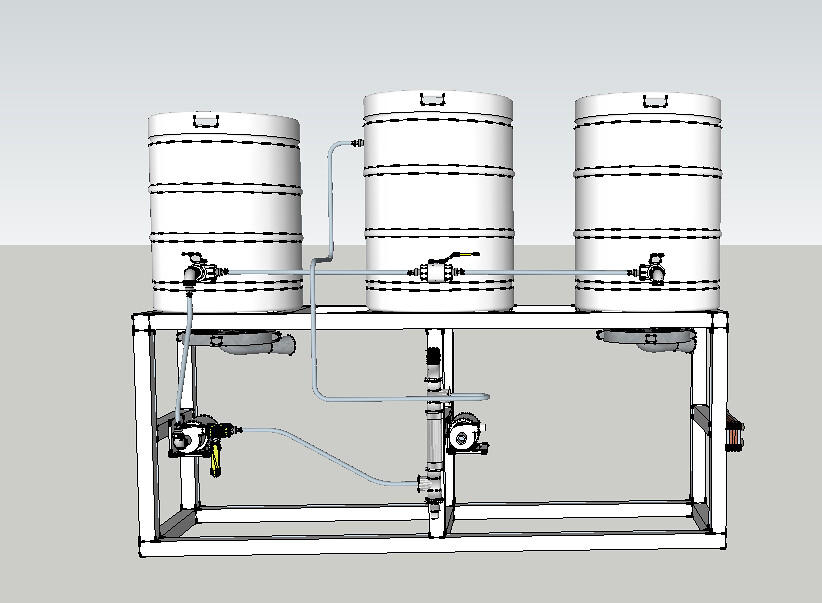

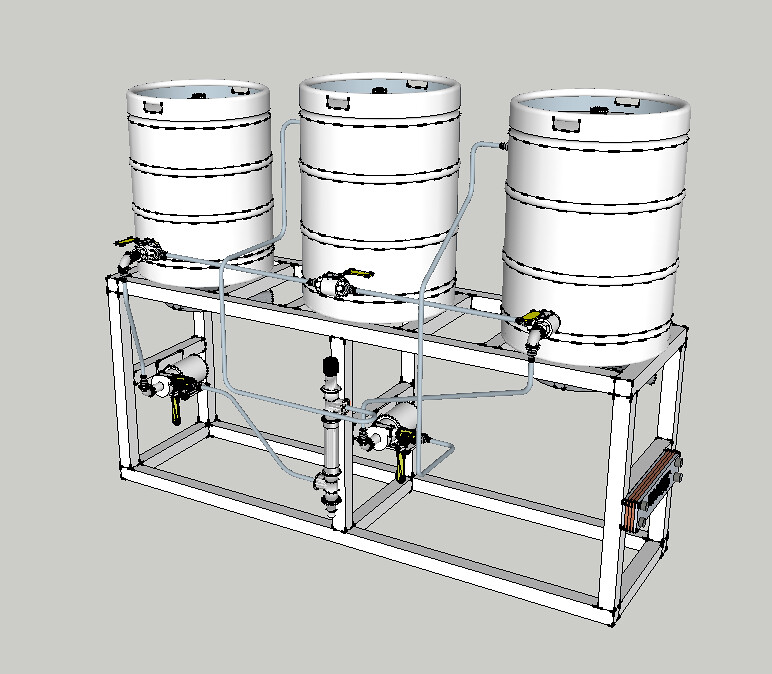

I am starting to design/purchase parts for a RIMS build using propane for the HLT and BK with a 5500 element in the HEX. I know how the systems work, but this is a lesson in planning so far. I thought I knew how to plumb the system but I have all but tied my brain in a knot trying to figure it out.

Anyways, I am planning it in sketchup. I linked my diagram so far down below in hopes that anyone could help me with the plumbing. I may have some help coming from the brewhardware guys but want any and all help I can get.

As of now I have kegs figured out and my pumps are in hand (Chuggers). Everything else is to come shortly. I hope.

RIMS 2 by HopticalIllusionist, on Flickr

Anyways, I am planning it in sketchup. I linked my diagram so far down below in hopes that anyone could help me with the plumbing. I may have some help coming from the brewhardware guys but want any and all help I can get.

As of now I have kegs figured out and my pumps are in hand (Chuggers). Everything else is to come shortly. I hope.

RIMS 2 by HopticalIllusionist, on Flickr