marcb

Well-Known Member

Pitching the starter!

marcb said:Pitching the starter!

Chamuco said:Yeah buddy! Now that's a starter.....ended up being 8 gallons?

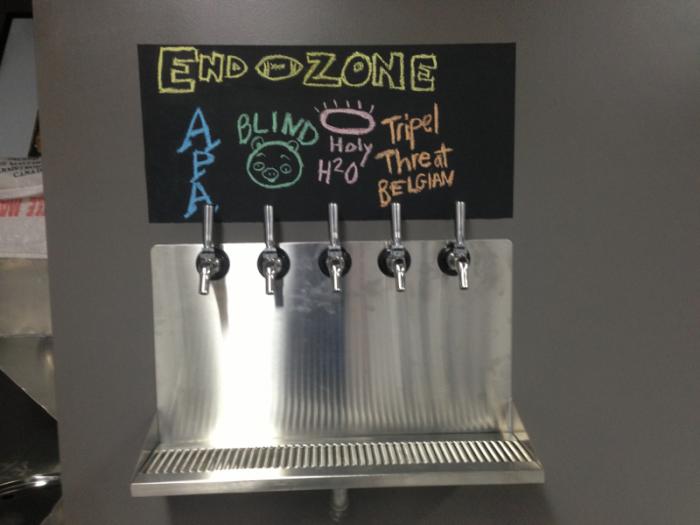

marcb said:Taps are installed on the cold room wall! Getting ready to roll!

Carlscan26 said:Shiny! Did you get that tray with a drain?

Yes sir. Beverage factory is the only one I could find that had the holes 4" on center with 5 taps. Fastev fabbed me an equally shiny piece to match it on the inside of the cold room. One thing I hadn't accounted for though is with the wall mount I cannot run my big tap handles! There isn't enough clearance and if I space them off the wall any further the stainless shanks aren't long enough to couple through the back. It's crazy but it all worked. Going to order some Williams stainless tap handles to round it all out and apply chalkboard paint above for the brews on tap.

kerklein2 said:Pick yourself up some of these for those big tap handles:

http://www.kegworks.com/angle-bonnet-for-draft-beer-faucet-855-p174031

unclephilly said:THIS.

This is the most awesome build I have ever seen someone do to their garage!

unclephilly said:...and lots of money and many, many beers!

jjadamsfb said:Don't forget SWMBO. She is obviously awesome and loves beer.

Lol, true although I've got to say that after lusting after used 2-3BBL systems for almost a year I ended up spending about as third as much to build as I would have spent buying a used system. The talented friends had much to do with that all working out! Cheers!

nvrstck said:Since you can get a similar 3bbl setup from psychobrew for about $15K, is it safe to say you have less than $5K in the brew setup (mash & boil equip only)? That's awesome! Inspirational!:rockin:

Washing kegs today!

Big_Cat said:What type of keg washer is that?

marcb said:A built by me keg washer ; )

BadDeacon said:And that makes it all worth it!! Congrats!

Francus said:So, when is the party?

marcb said:Sunday, nothing like a party at the house as a forcing function for getting stuff done!

Tankless is live and generates 185 degree water full throttle! Amazing!

Boar Beer said:marcb

Nice looking coils they do look hard to clean and might allow unwanted bugs into your brew.

Are you going to use them to make lagers or just to control your fermentation temperature?

Great thread BTW

Enter your email address to join: