drkwoods, thanks for sharing all of these details - it's very helpful for us. I'm struggling with a very similar situation. I've got a side by side, removed the damper (it was a stepper motor and couldn't be easily controlled by my temp controllers), and installed basically the same fan as you (different branding, but it's 110v 68cfm). Cooling the fridge side down works great with this setup when the ambient air temperature in the garage is greater than the set point. I'm finding though if I need to heat the fridge side, I get a lot of hot air bleeding back to the freezer side when the heater kicks in. I've tried all sorts of things to fashion a flap/baffle over the fan ensure only one way air flow. The problem is that since there are two openings (top and bottom) between the chambers, even if I had perfect 1 way air control on both openings, there is still enough air movement from the evaporator fan (which sits on top of the coils in my freezer) when the cooling cycle is running to make sure air is circulating, even when my "baffle" fan is off.

This creates a situation where the compressor and the heater are working against each other to try and hold temperatures on each side. The heater kicks on to attempt to keep the fridge at 65ºF, which causes some hot air to bleed back into the freezer, which causes the compressor to kick on to try and keep the freezer at 38ºF, which then causes more cold air to cycle back into the fridge side, and the cycle repeats. I have found that I can sometimes hold both sides within a few degrees of the desired set points, but the freezer compressor runs pretty much constantly to achieve this.

I'm considering just separating the two chambers for the winter, since the air temperature in the garage is usually below my desired fermentation point (for ales), but when I'm out in the garage and brewing the air temps rise pretty quickly (I have a natural gas heater in there, that I only use when I'm in the building). I'd also like to have the option to lower the fridge side to lagger temps without stuffing and un-stuffing insulation each time.

Any thoughts?

Thanks again!

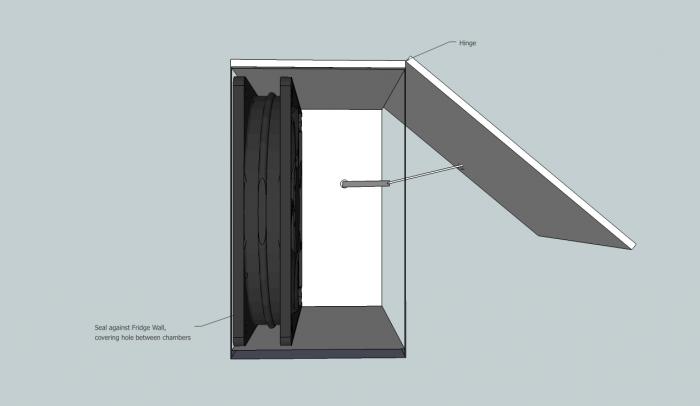

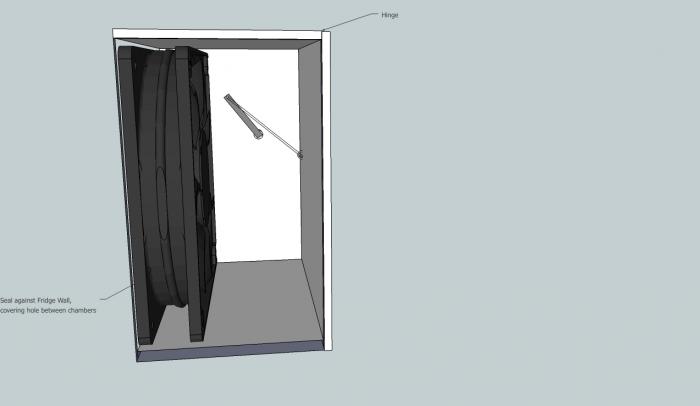

I went ahead and blocked both openings with some rubber insulation (I cutup an old mousepad, works great), and as expected I am able to maintain my temps fairly precisely (a solid 38ºF on the freezer side and 65ºF on the fridge side.) I think it would be fine to just leave it like this and plan on removing the insulation when I want to go to summer mode a couple of times a year. I'm not one to leave well enough alone though so I've sketched up a solution using an Arduino and a stepper motor to automatically control a flap over the fan on the upper hole when the fridge cooling cycle kicks in. The idea is that when cooling is required the 4" 68cfm fan will kick in and the stepper motor will open a 4" flap. When not running, the flap will shut tight against a rubber seal. Basically this is what the fridge was doing originally before I started modifying it (minus the fan). I ordered the parts for the project today and will gelt started on the build in a few weeks. I'll document the process in my big

I went ahead and blocked both openings with some rubber insulation (I cutup an old mousepad, works great), and as expected I am able to maintain my temps fairly precisely (a solid 38ºF on the freezer side and 65ºF on the fridge side.) I think it would be fine to just leave it like this and plan on removing the insulation when I want to go to summer mode a couple of times a year. I'm not one to leave well enough alone though so I've sketched up a solution using an Arduino and a stepper motor to automatically control a flap over the fan on the upper hole when the fridge cooling cycle kicks in. The idea is that when cooling is required the 4" 68cfm fan will kick in and the stepper motor will open a 4" flap. When not running, the flap will shut tight against a rubber seal. Basically this is what the fridge was doing originally before I started modifying it (minus the fan). I ordered the parts for the project today and will gelt started on the build in a few weeks. I'll document the process in my big