TheFlyingBeer

Well-Known Member

Well here goes the story of my new keezer:

Upon graduation I landed a job just outside of Baltimore and made the move from Minneapolis just a few weeks ago. The majority of my brewing equipment made the move with me but my old kegerator was staying put at college. Getting away from the college life style I no longer required a kegerator to hold 1/2 bbls of Keystone Light and the like so I decided to build a keezer dedicated to homebrew.

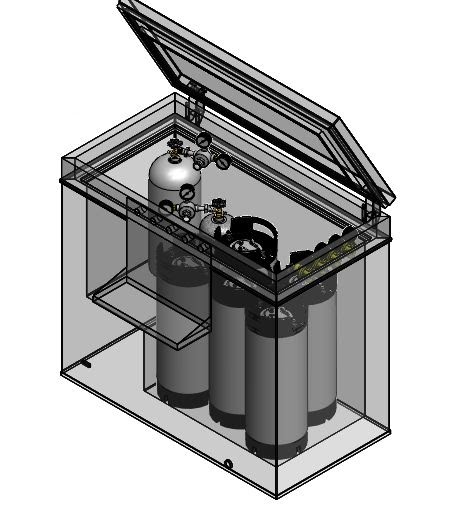

I checked out the keezer sizing thread and was originally going to go with the 7.2 cu.ft. Magic Chef from Home Depot but I really wanted the ability to hold 5 kegs and SWMBO wanted to keep the size down as much as possible. We settled on a 9.0 cu.ft. Frigidaire from Lowes for around $260. I made some very rough estimates at the store and determined I 'should' be able to squeeze 5 kegs in the lower portion and keep my CO2 and Nitro tank on the hump.

Turns out that my measurements were so close that 1/8ths of an inch mattered. I had to shave off the rubbers ridges from the tops and bottoms of my kegs.

I currently only have three kegs but I have moved them around and 5 should fit extremely tightly.

I made a collar for the freezer using 5/4" x 4" sanded and primed pine from Home Depot, using a good old mitre box and hand saw.

I have a 10lb CO2 tank (red gas lines) and a ~5lb Nitrogen tank (blue gas line) inside on the hump. The CO2 primary line feeds my 4 secondaries. I am waiting on the gauge and shutoff valve for one of them. I used power wire and some washers to mount the secondaries so that they could move around when kegs needed to be swapped out. Everything that touches the beer is stainless, and hopefully with the Perlicks there will be no more sticky faucets.

I placed a piece of plexiglass in between two runners on the top of the freezer lid so I could insert the names of each item on tap.

In addition to the secondary gauge and shutoff valve I am waiting on a fourth Perlick faucet, some fittings, 5 black pub handles, and two more kegs... then the Keezer will be finished.

I am still debating how to mount the temperature probe and what to do with the drain on the wall mount drip tray. I think for the drain I will just plug it for now and figure that out later.

Well there it is my new keezer which at the moment sits empty but will be full as soon as I can keg the beers that traveled with me and brew a couple new ones.

If anyone wants a parts list let me know... I try not to look at the total cost and there is no way in hell SWMBO will ever know the real cost of this thing.

Upon graduation I landed a job just outside of Baltimore and made the move from Minneapolis just a few weeks ago. The majority of my brewing equipment made the move with me but my old kegerator was staying put at college. Getting away from the college life style I no longer required a kegerator to hold 1/2 bbls of Keystone Light and the like so I decided to build a keezer dedicated to homebrew.

I checked out the keezer sizing thread and was originally going to go with the 7.2 cu.ft. Magic Chef from Home Depot but I really wanted the ability to hold 5 kegs and SWMBO wanted to keep the size down as much as possible. We settled on a 9.0 cu.ft. Frigidaire from Lowes for around $260. I made some very rough estimates at the store and determined I 'should' be able to squeeze 5 kegs in the lower portion and keep my CO2 and Nitro tank on the hump.

Turns out that my measurements were so close that 1/8ths of an inch mattered. I had to shave off the rubbers ridges from the tops and bottoms of my kegs.

I currently only have three kegs but I have moved them around and 5 should fit extremely tightly.

I made a collar for the freezer using 5/4" x 4" sanded and primed pine from Home Depot, using a good old mitre box and hand saw.

I have a 10lb CO2 tank (red gas lines) and a ~5lb Nitrogen tank (blue gas line) inside on the hump. The CO2 primary line feeds my 4 secondaries. I am waiting on the gauge and shutoff valve for one of them. I used power wire and some washers to mount the secondaries so that they could move around when kegs needed to be swapped out. Everything that touches the beer is stainless, and hopefully with the Perlicks there will be no more sticky faucets.

I placed a piece of plexiglass in between two runners on the top of the freezer lid so I could insert the names of each item on tap.

In addition to the secondary gauge and shutoff valve I am waiting on a fourth Perlick faucet, some fittings, 5 black pub handles, and two more kegs... then the Keezer will be finished.

I am still debating how to mount the temperature probe and what to do with the drain on the wall mount drip tray. I think for the drain I will just plug it for now and figure that out later.

Well there it is my new keezer which at the moment sits empty but will be full as soon as I can keg the beers that traveled with me and brew a couple new ones.

If anyone wants a parts list let me know... I try not to look at the total cost and there is no way in hell SWMBO will ever know the real cost of this thing.

. No I didn't shop for beer equipment on company time if anyone is wondering...

. No I didn't shop for beer equipment on company time if anyone is wondering...