jiggs_casey

Well-Known Member

I rent. Anyway, a while back, I noticed an usused 220v connector in the garage. I thought at first that maybe a previous tennant may have used it for a second dryer.

I got curious about it and found out it is not the type used by a dryer. Instead of two straight and one 'L' shaped slots, it has three straight slots. A friend said that this is the type for a range. However, it's a 30 amp cable. The marking on the cable is 'AWG 10-3 / TYPE NM-B' As I understand, an electric range has to use a 50 amp cable / breaker or you run the risk of fire.

I was able to trace the cable all the way back, through the house, to the circuit breaker panel. So, I know it's live and waiting for me to put it to good use...

So, here are my questions...

How do I know what size breaker this wire is connected to? 30A vs 50A.

Given the markings on the cable, are my findings correct in that is a 30A rated cable?

Is the socket description, 'three straight slots' the type that is used for an electric range?

Is it possible for me to use this in an 'all-electric' configuration?

Could a previous tennant have been a homebrewer!?

I got curious about it and found out it is not the type used by a dryer. Instead of two straight and one 'L' shaped slots, it has three straight slots. A friend said that this is the type for a range. However, it's a 30 amp cable. The marking on the cable is 'AWG 10-3 / TYPE NM-B' As I understand, an electric range has to use a 50 amp cable / breaker or you run the risk of fire.

I was able to trace the cable all the way back, through the house, to the circuit breaker panel. So, I know it's live and waiting for me to put it to good use...

So, here are my questions...

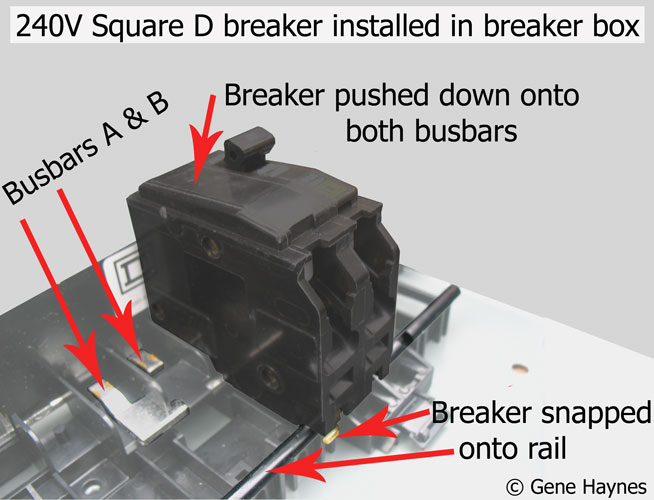

How do I know what size breaker this wire is connected to? 30A vs 50A.

Given the markings on the cable, are my findings correct in that is a 30A rated cable?

Is the socket description, 'three straight slots' the type that is used for an electric range?

Is it possible for me to use this in an 'all-electric' configuration?

Could a previous tennant have been a homebrewer!?