magnj

Well-Known Member

Hello all, long story short a friend and I would like to go 50/50 on a 10 gallon brew rig. I'm currently doing 3 gallon BIAB batches and it's a lot of work for a little beer.

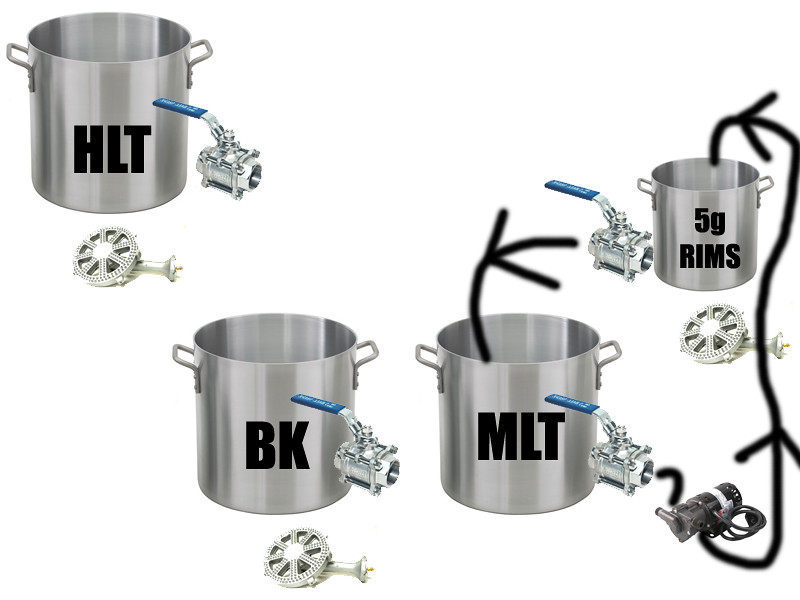

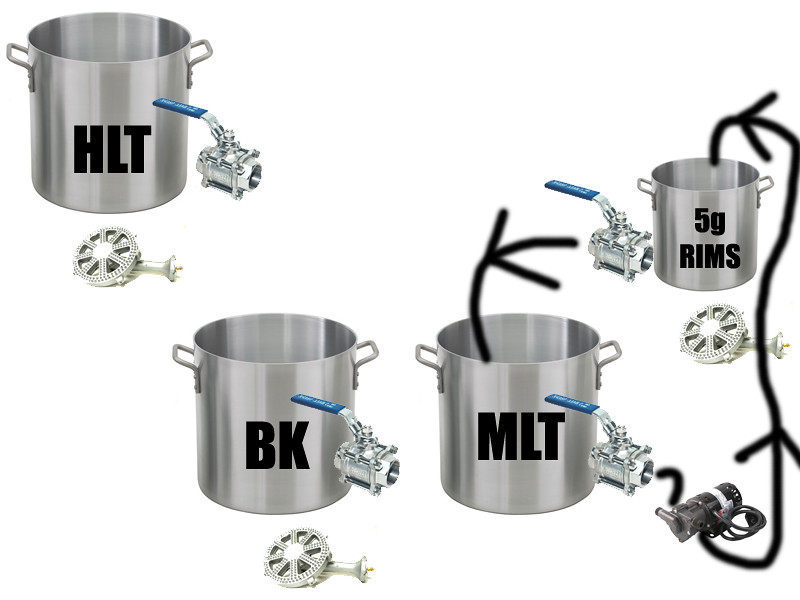

Here's what I'm thinking: 2 tiers, 4 vessels, direct fire ( fire fire ) RIMS. BK and MLT on the bottom, HLT and RIM vessel up top. Since I have a 5 gallon kettle now I figured I'd avoid any possibility of scorching grain by using a second vessel to adjust with heat...

My main concerns, questions revolve around the burner(s) (maybe the HLT too but because of the cost I'm not sure it's really worth it) with the pilot. I'm thinking digital thermostat ala Johnson A419 to toggle the gas valve. What are the chances there is a kit out there including the LP reg, solenoid valve, pilot and burner? Because I read a lot of these threads and although helpful I'm left a bit confused on parts and I don't want to blow up.

And electric is out of the question unless it's cheaper and I don;t need anything than 1 or 2 standard outlets.

Other than that I have to figure out a pump, false bottom, valves, etc., but that I'm less lost on.

Thoughts? Thanks!

Here's what I'm thinking: 2 tiers, 4 vessels, direct fire ( fire fire ) RIMS. BK and MLT on the bottom, HLT and RIM vessel up top. Since I have a 5 gallon kettle now I figured I'd avoid any possibility of scorching grain by using a second vessel to adjust with heat...

My main concerns, questions revolve around the burner(s) (maybe the HLT too but because of the cost I'm not sure it's really worth it) with the pilot. I'm thinking digital thermostat ala Johnson A419 to toggle the gas valve. What are the chances there is a kit out there including the LP reg, solenoid valve, pilot and burner? Because I read a lot of these threads and although helpful I'm left a bit confused on parts and I don't want to blow up.

And electric is out of the question unless it's cheaper and I don;t need anything than 1 or 2 standard outlets.

Other than that I have to figure out a pump, false bottom, valves, etc., but that I'm less lost on.

Thoughts? Thanks!