DilvishTheDamned

Well-Known Member

- Joined

- Apr 4, 2009

- Messages

- 70

- Reaction score

- 2

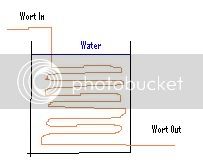

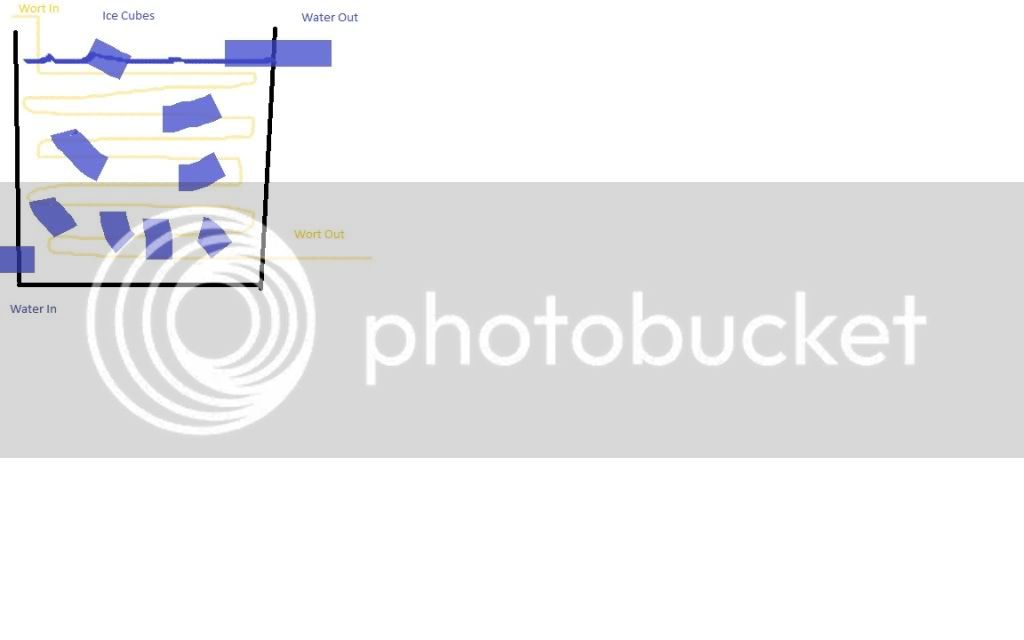

Got an idea for a hybrid chiller, and I'm wondering if anybody can spot the flaws.

Basically my idea is to put the copper coils in a 4-5 gallon bucket. The bucket is then filled with ice and water, and the hot wort run through the inside of the copper coils like a counter flow wort chiller. There's a hole at the bottom of the bucket to allow copper coil to drain out using gravity.

Pros:

* Allows use of ice

* Saves on water bills

* Allows me to convert my immersion wort chiller simpler, basically just one bend, instead of going through all the trouble of straightening it out, inserting it into the hose.

* Requires much fewer fittings, maybe one for running the coil out the bottom of the bucket.

Cons:

* Water will be heated by the water (This could be fixed by dumping the water)

???

I'm not even sure that keeping the water is a bad thing, since it's going to be around 40-50 degrees, which is always going to be colder than the hot wort.

Basically my idea is to put the copper coils in a 4-5 gallon bucket. The bucket is then filled with ice and water, and the hot wort run through the inside of the copper coils like a counter flow wort chiller. There's a hole at the bottom of the bucket to allow copper coil to drain out using gravity.

Pros:

* Allows use of ice

* Saves on water bills

* Allows me to convert my immersion wort chiller simpler, basically just one bend, instead of going through all the trouble of straightening it out, inserting it into the hose.

* Requires much fewer fittings, maybe one for running the coil out the bottom of the bucket.

Cons:

* Water will be heated by the water (This could be fixed by dumping the water)

???

I'm not even sure that keeping the water is a bad thing, since it's going to be around 40-50 degrees, which is always going to be colder than the hot wort.