I am reposting this with an updated title and some revisions

So basically looking to do the same main panel build as BrewskiBroski with a keezer/ferm sub panel

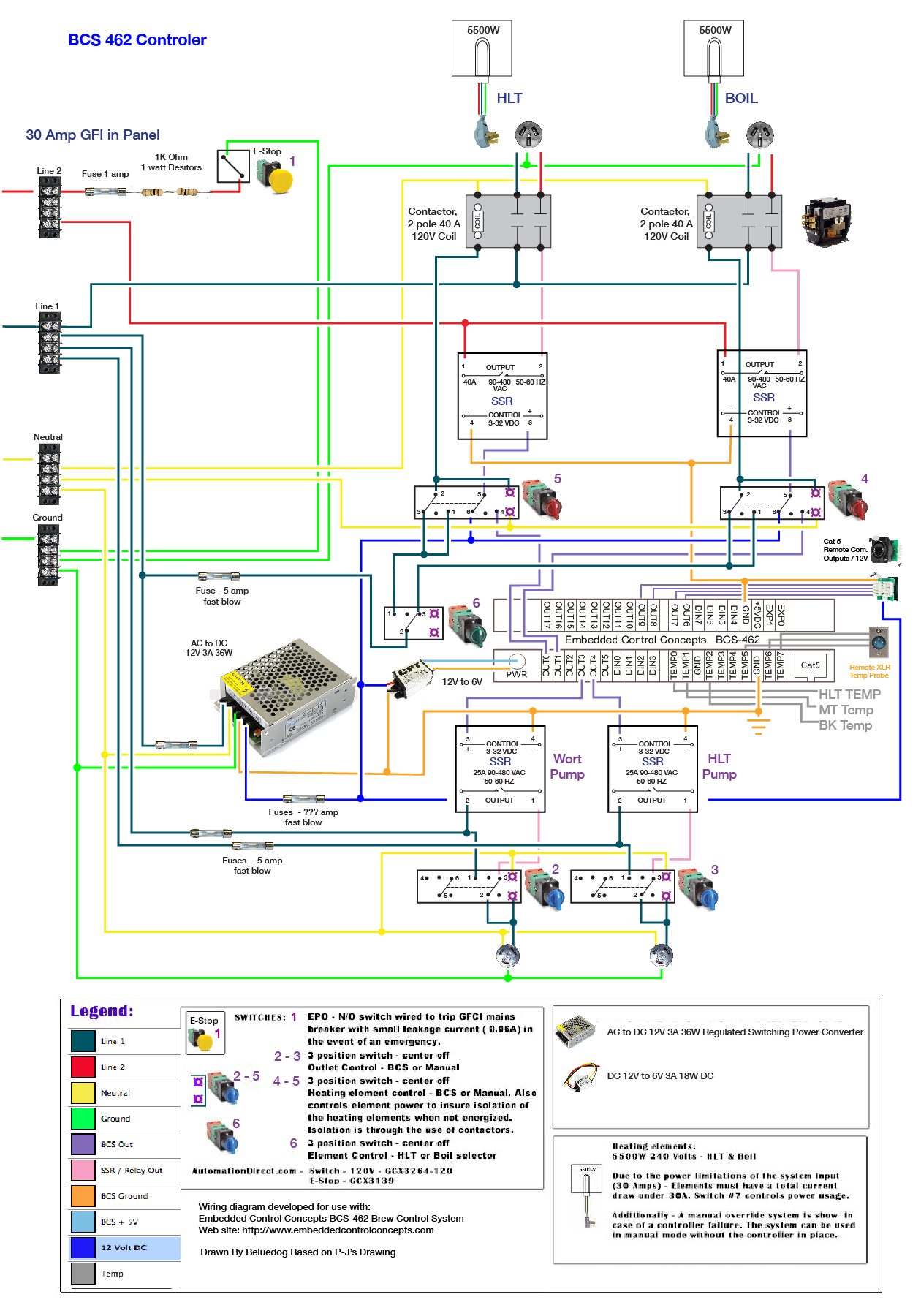

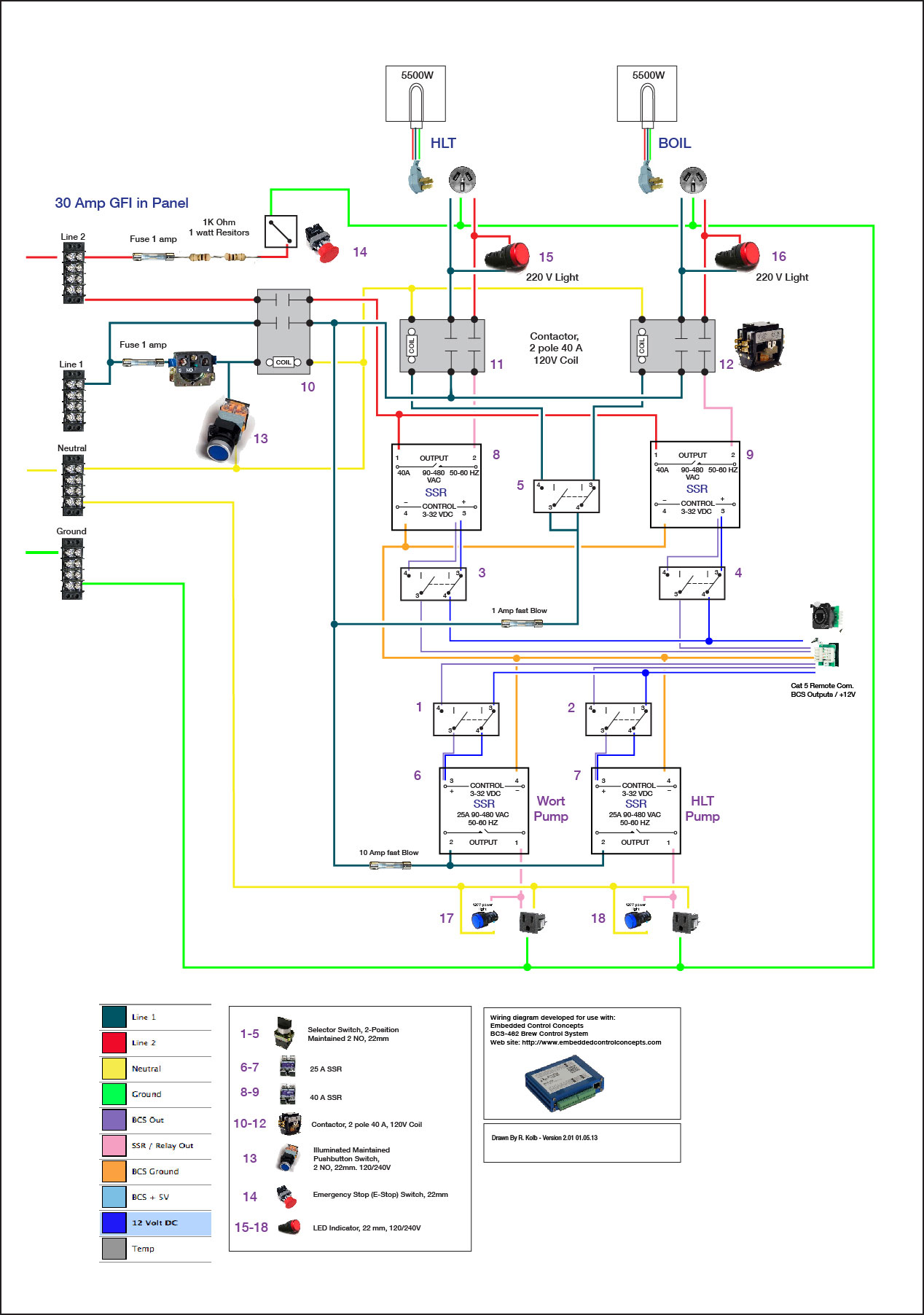

found here: https://www.homebrewtalk.com/f51/he...tric-bcs-460-2-element-brewing-system-300259/

And need some help/advice on build/schematic

50Amp Panel Mounted GFI

3 - 20 gal kettles

HLT and BK both have 5500W heating elements

HERMS system with the heat exchange coils in the HLT

2 march pumps

1Keezer - cool

1Ferm Chamber - Heat/Cool

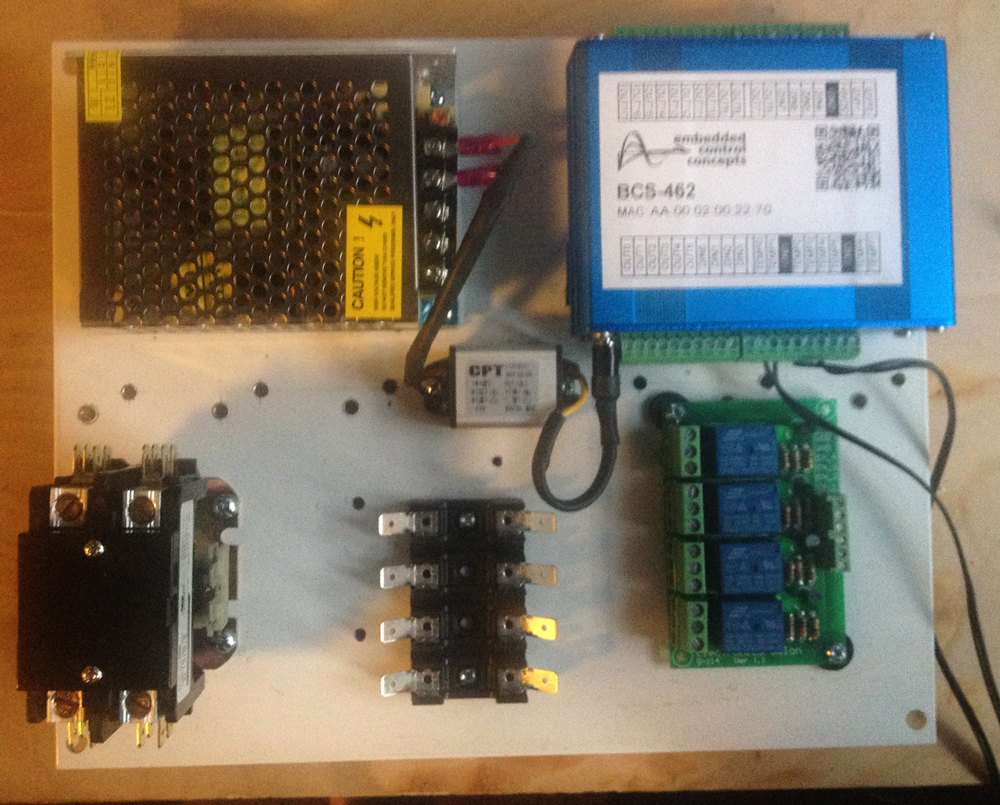

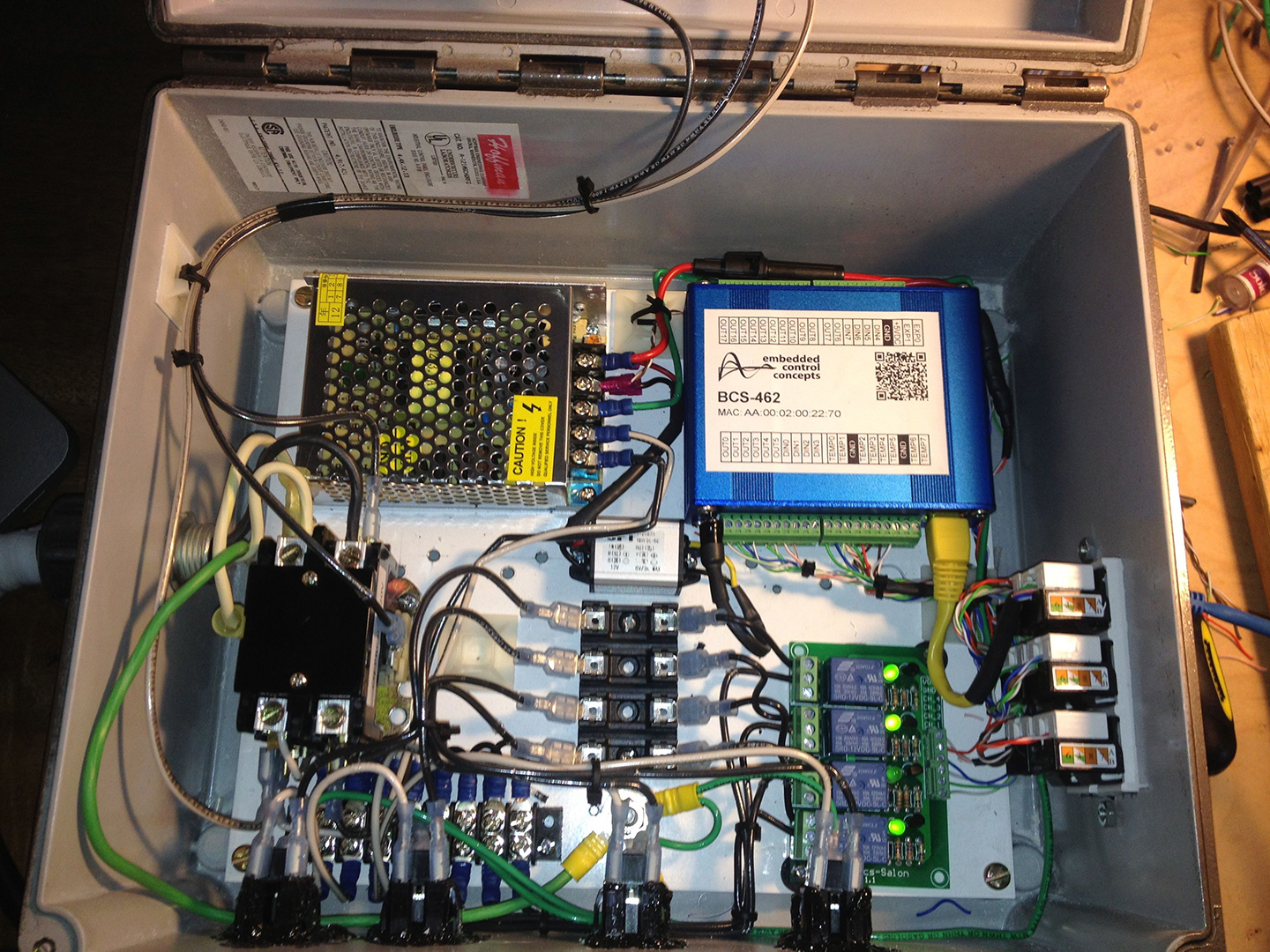

BCS 462 to maintain temps and on/off for pumps

At any given time, I need to run 1 element and 2 pumps (never running both elements at the same time) as well as ferm freezer and keezer

What i'd like:

A panel with switches for manual/auto(BCS 462)/off for each element and both pumps as well as an e-switch, master key switch and indicator lights for ferm/keezer

Wondering if its possible to use this for pumps, keezer and ferm:

http://www.amazon.com/dp/B007BKARFU/?tag=skimlinks_replacement-20

seems cleaner and expandable than going ssr route

And use this for 5V power: http://dx.com/p/5v-3-8a-regulated-s...ilver-145841?gclid=CL_e5piDqbQCFUKd4AoddH0AIg

Also considering moving the ferm/keezer to its own sub box. Possibly some sort of pluggable A/C, cat 5 for relay control and power and 3 wire shielded for temp probes. If I went this route i would use ssr's for pumps in main control panel.

Any input would be appreciated, thanks!

So basically looking to do the same main panel build as BrewskiBroski with a keezer/ferm sub panel

found here: https://www.homebrewtalk.com/f51/he...tric-bcs-460-2-element-brewing-system-300259/

And need some help/advice on build/schematic

50Amp Panel Mounted GFI

3 - 20 gal kettles

HLT and BK both have 5500W heating elements

HERMS system with the heat exchange coils in the HLT

2 march pumps

1Keezer - cool

1Ferm Chamber - Heat/Cool

BCS 462 to maintain temps and on/off for pumps

At any given time, I need to run 1 element and 2 pumps (never running both elements at the same time) as well as ferm freezer and keezer

What i'd like:

A panel with switches for manual/auto(BCS 462)/off for each element and both pumps as well as an e-switch, master key switch and indicator lights for ferm/keezer

Wondering if its possible to use this for pumps, keezer and ferm:

http://www.amazon.com/dp/B007BKARFU/?tag=skimlinks_replacement-20

seems cleaner and expandable than going ssr route

And use this for 5V power: http://dx.com/p/5v-3-8a-regulated-s...ilver-145841?gclid=CL_e5piDqbQCFUKd4AoddH0AIg

Also considering moving the ferm/keezer to its own sub box. Possibly some sort of pluggable A/C, cat 5 for relay control and power and 3 wire shielded for temp probes. If I went this route i would use ssr's for pumps in main control panel.

Any input would be appreciated, thanks!

Last edited by a moderator: