GregKelley

Well-Known Member

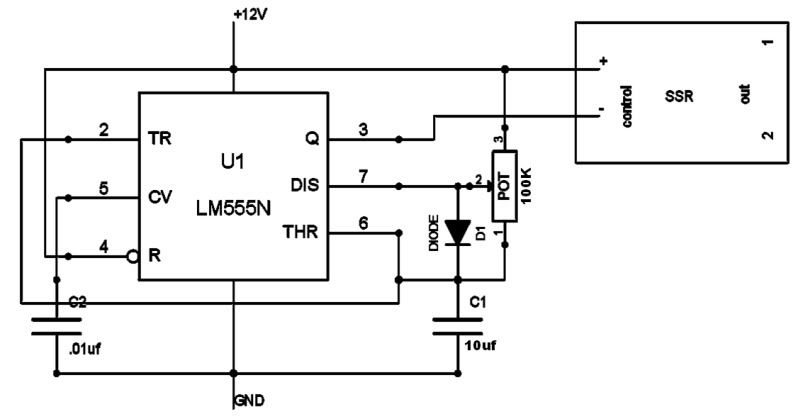

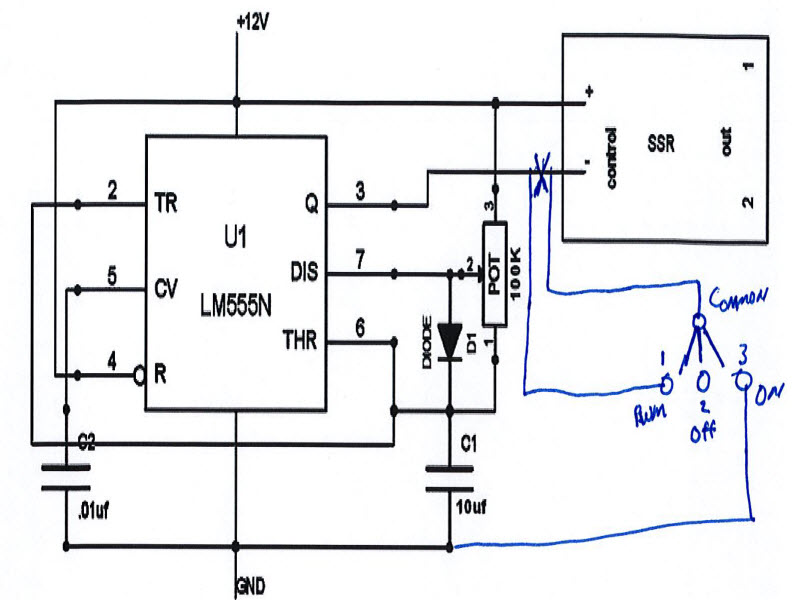

I built my PWM using the information in this post. Instead of the 33μF cap, I'm using a 22 (because that was what I found).

When I connect everything up and I put my voltmeter on the output, I get 0v when the pot is turned all the way counterclockwise. Great, power is out. However, when I turn it all the way clockwise, I see my voltmeter cycle between 5v and 0v. I thought I should get 5v the entire time. Am I wrong?

When I connect everything up and I put my voltmeter on the output, I get 0v when the pot is turned all the way counterclockwise. Great, power is out. However, when I turn it all the way clockwise, I see my voltmeter cycle between 5v and 0v. I thought I should get 5v the entire time. Am I wrong?