Scut_Monkey

Well-Known Member

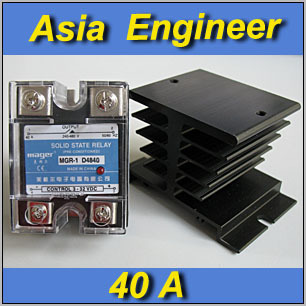

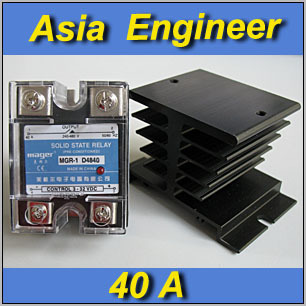

So I'm running into a problem with building my electrical enclosure. I'm following Kal's build but I decided to use the smaller heatsinks that came with my SSRs. I bought the SSRs from ebay and they just like the small heatsink/ssr combo below (middle picture).

The problem is that where the heatsink and SSR attach to each other is almost exactly the same size. This leaves me no room to mount the heatsink to the enclosure like Kal did (first picture). Looking at the heatsink that Auberins provides it shows to have a much larger mounting surface which eliminates this problem (third picture below).

Has anyone run into this for their build? I'm not sure how to overcome it without buying a new large heatsink.

The problem is that where the heatsink and SSR attach to each other is almost exactly the same size. This leaves me no room to mount the heatsink to the enclosure like Kal did (first picture). Looking at the heatsink that Auberins provides it shows to have a much larger mounting surface which eliminates this problem (third picture below).

Has anyone run into this for their build? I'm not sure how to overcome it without buying a new large heatsink.