Hoosier

Well-Known Member

Hello Everyone,

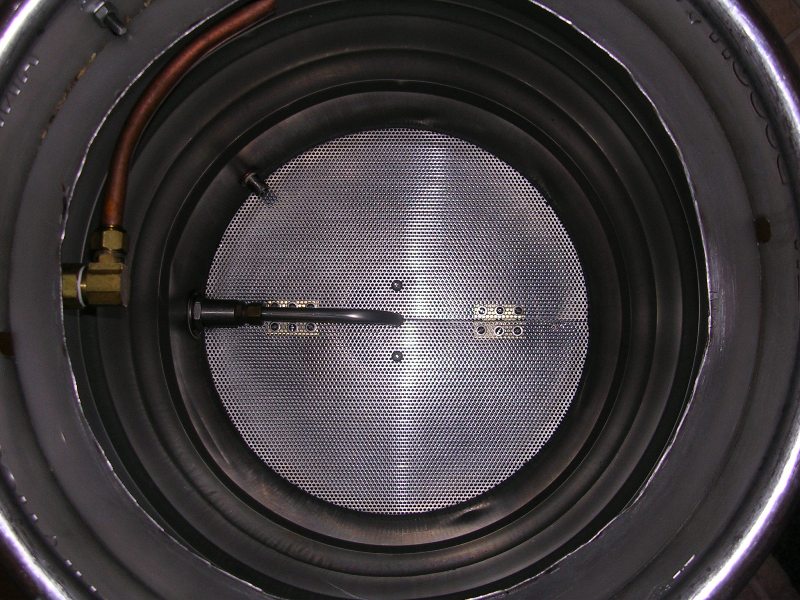

I am planning on converting a sanke keg to a direct fire mash/lauter tun. I dug around the project locater but I was unable to find anything on this. I plan on picking up a ss flase bottom for it and the construction of the lauter system is easy. My question is what are you all using for insulation and lid during the mash. Please post any advice and pic's if available. Thanks in advance.

R,

Hoosier

I am planning on converting a sanke keg to a direct fire mash/lauter tun. I dug around the project locater but I was unable to find anything on this. I plan on picking up a ss flase bottom for it and the construction of the lauter system is easy. My question is what are you all using for insulation and lid during the mash. Please post any advice and pic's if available. Thanks in advance.

R,

Hoosier