Oh no! Isn't there any way for the system to just go back to doing what it was doing prior to the failure? If not, are you considering hooking it up to a UPS?

So, there are a couple things going on here:

1) The BCS-460 as designed (for whatever reason) will not resume where it left off when it comes back on from power loss. I think this stems from the fact that it's really made for automated brewing and not fermenting. If that were to happen in an automated brewing system, there could be bad consequences.

2) The load of an A/C is way too high for a UPS. I could rewire it to run the A/C off it's own outlet and everything else off a UPS. The end result is it would buy you more time as you have a reservoir of chilled liquid. However, I think that's kind of overkill.

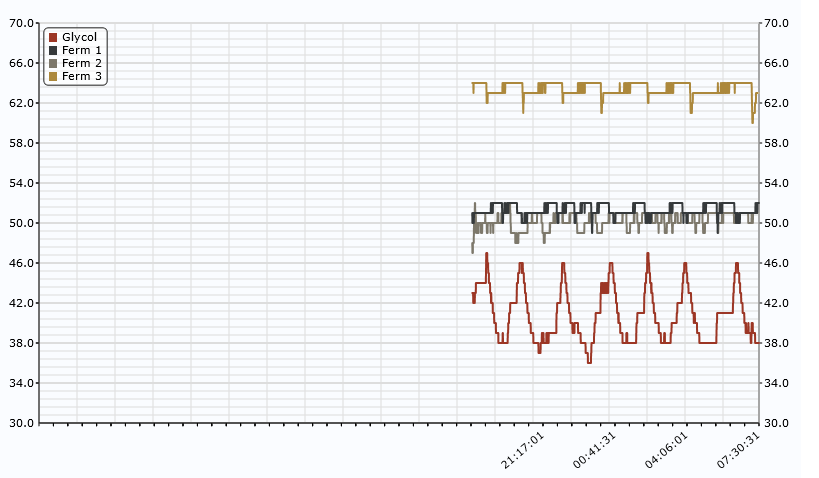

Really, this was kind of a perfect storm around here. We've lost power maybe twice in the 3 years I've lived here (including last night) and never for more than 5-10 seconds. On top of that, ambient temps in the garage were 85-90 since we're going through a heat wave. If I had insulated the conicals ahead of time, it probably would have knocked 10 degrees off the top in the morning. Temporarily reaching 68 I could get away with. 78, I don't think so.

Some time in the future, I'd like to redesign the controller around a

BeagleBone, which would give me a lot more power to work with and would remove the limitations of the BCS. However, starting in August, my free time is going to be extremely limited and I don't have nearly the time in the interim to teach myself everything I'd need for a BeagleBone.

So, in the mean time, I'll dump the german pils and brew a czech pils later this week. The design of this system has really cut in to my brew time lately and I really want to start experimenting with decoction mashes. So, that's where I'm going to spend a lot of my time.

I still have a few bits to insulate here and there, but for the most part, I'd call this project complete. I'm going to watch the temps tomorrow and see how much of a difference the insulation makes. Other than that, I need to replace the wifi repeater I used as it's overheating in the box.