It's time to start malting!

I had a look at the food dehydrator that I borrowed, and I could only fit about 2 pounds of barley on each of the 4 trays it comes with. That means that 8 pounds per malting batch would be pushing what I could dry in one go, so I decided to start with a 6 pound batch to malt.

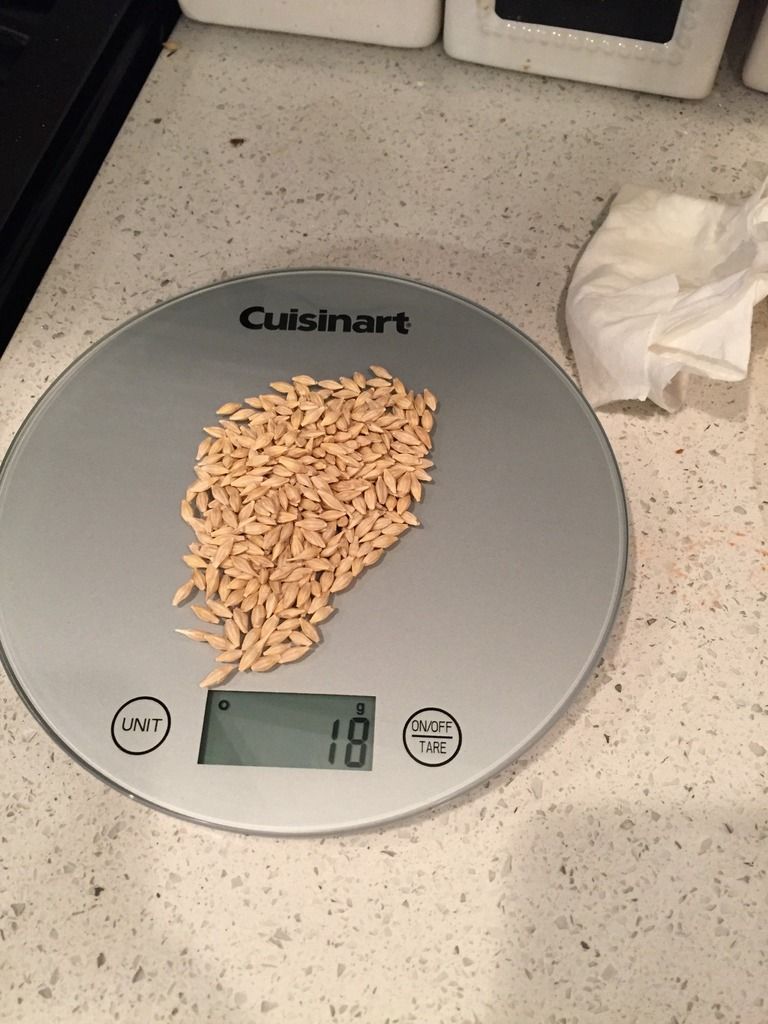

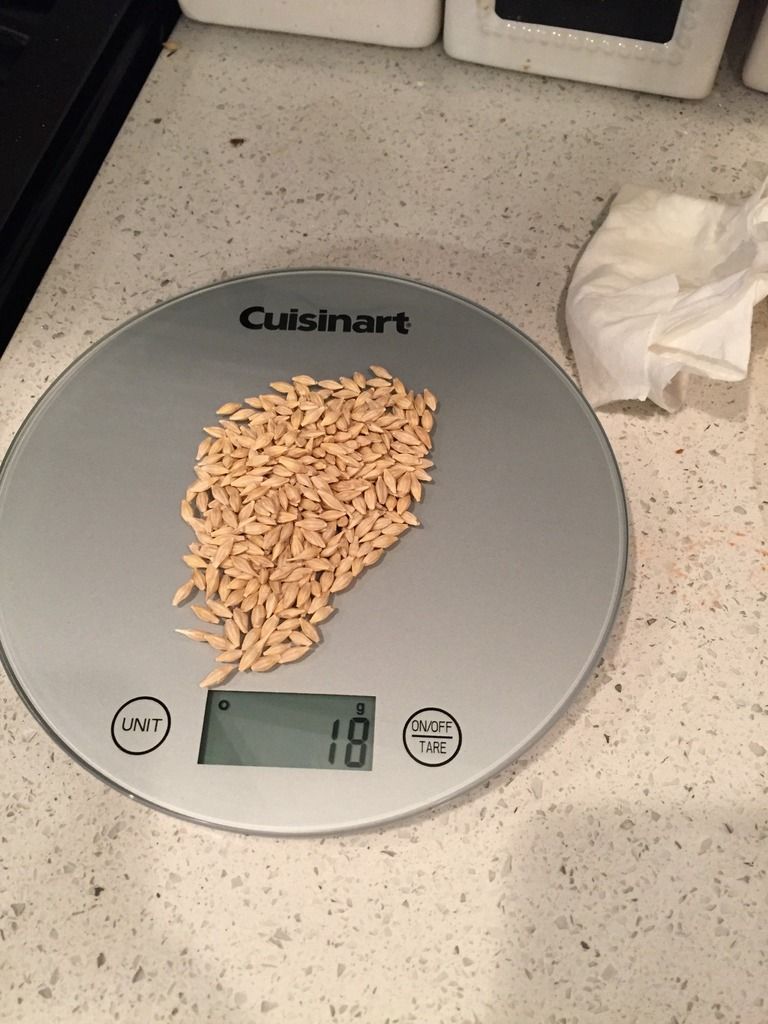

I wanted to know how much the seeds weighed, since the change in water content (and thus weight) of the kernels is an important indicator at several steps of the malting process. I counted out 400 barleycorns and found they weighed 18 grams. Now if I want to know my water weight I can just count out a number of kernels and weigh them, if the whole batch is too unwieldy.

Next I got my two Home Depot buckets, one of which I bough specially for this purpose last night, and cleaned them out good. I used a bleach solution on the old bucket that's been caked in mud after scrubbing it out well. I don't know if that's important, but after rinsing it half a dozen times I figured it couldn't hurt.

I used a drill to put about 20 holes in the bottom of the new one, and set it in the intact one. I can now easily drain the barley between soaks.

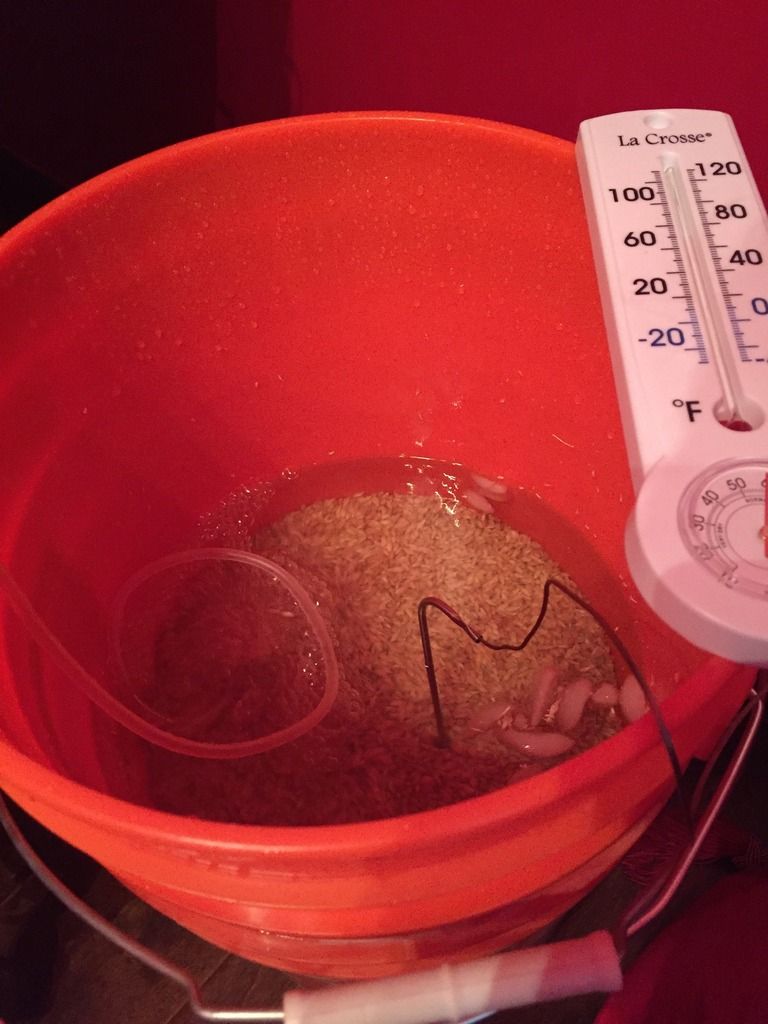

Finally, I weighed out 6 pounds of my Endeavour barley, added it to the buckets, covered it in water, threw in some ice cubes, and added a air stone:

The air stone was $20 and it to help the barley seeds not run out of oxygen and drown. I'll be leaving the seeds in the water for around 8 hours today, so I can't have them run out of oxygen.

The temperature of the water was 70 F when I got it from the sink, and the ice cubes took it down to around 62 F. The room (my bar) is 63 F this morning, and stays in the 60's. I've read where 55 F is the temperature you're aiming for, but I've heard of folks getting by at closer to room temp.

I'll let this soak and breath for 8 hour steps until the barely has gained 35% mass, bringing it up to 39-45% moisture, changing the water each time. Then it will be time to set the barley in mats to germinate.