BadgerBrewer

Well-Known Member

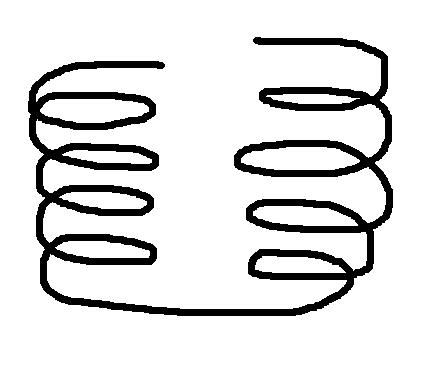

I am looking to build a chiller, either a CFC or an IC to handle cooling wort in my newly built 15.5 gallon keggle. I am leaning toward something like Jamil's with the whirlpool return, which gets the wort circulating against the IC, but I wanted to see what everyone else built and make a final decision. I have read a ton of posts and there are so many different ways to build one, I wanted to get a thread going with them all in one place for other folks like myself looking to DIY. I know that there are a million different ways to build one so show 'em off!