CollinsBrew

Well-Known Member

Alllllriiiiight! I finally got the gas manifold all put together and the chiller mounted. I forgot to take pics of the chiller so I'll have to add it later.

So, I ended up using yellow teflon tape on all of my gas connections and haven't had any leaks. I went ahead and ran all three burners as low pressure which meant I only had to buy one regulator for the whole deal. As far as propane is concerned, all I have left is to mount the pilot lights and the thermocouples.

Here's the manifold with the valves:

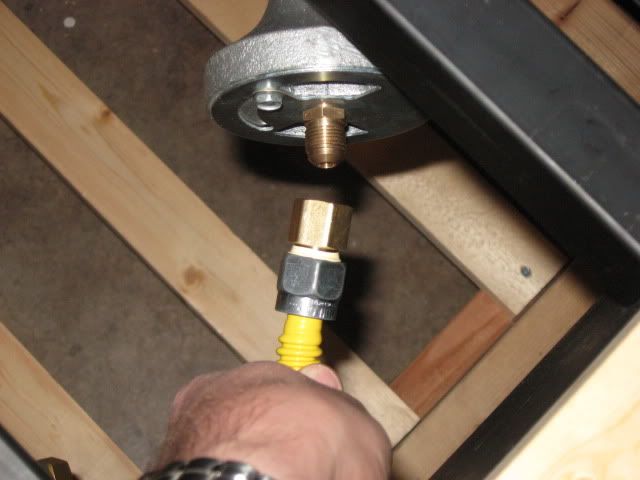

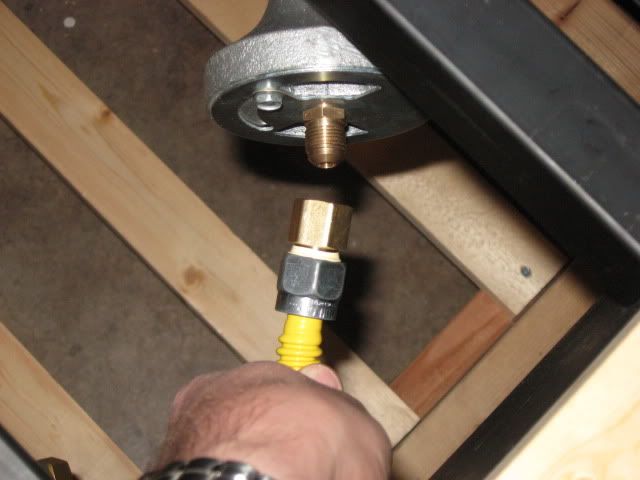

Where the manifold attaches to the hose that's attached to the tank. I had to use a 1/2" FIP to 3/8" FIP connected to a 3/8" MIP nipple to fit the hose.

One of the valves. You can see that the pipe goes into the gas rated ball valve and then into another 2" pipe and then threads directly into the valve. On the output of the valve you can see the connector that came with the hose. It's a 1/2" MIP to 3/8" Flare fitting with a built in safety valve.

This is the connector to the burner. I've seen quite a few people in other threads with questions on how to connect these to the burner. The fitting here is a 3/8" Flare to 1/4" FIP.

I drilled the orifices for all three burners. On one of the bigger banjos, a 3/32" bit did the trick. On the other, I ended up going to a size 40 wire gauge bit to get a flame that was more blue than yellow. That one was a real B*. It would give me an ok flame but would pulse for some reason where the other orifice worked fine after drilling it once to 3/32".

So, I ended up using yellow teflon tape on all of my gas connections and haven't had any leaks. I went ahead and ran all three burners as low pressure which meant I only had to buy one regulator for the whole deal. As far as propane is concerned, all I have left is to mount the pilot lights and the thermocouples.

Here's the manifold with the valves:

Where the manifold attaches to the hose that's attached to the tank. I had to use a 1/2" FIP to 3/8" FIP connected to a 3/8" MIP nipple to fit the hose.

One of the valves. You can see that the pipe goes into the gas rated ball valve and then into another 2" pipe and then threads directly into the valve. On the output of the valve you can see the connector that came with the hose. It's a 1/2" MIP to 3/8" Flare fitting with a built in safety valve.

This is the connector to the burner. I've seen quite a few people in other threads with questions on how to connect these to the burner. The fitting here is a 3/8" Flare to 1/4" FIP.

I drilled the orifices for all three burners. On one of the bigger banjos, a 3/32" bit did the trick. On the other, I ended up going to a size 40 wire gauge bit to get a flame that was more blue than yellow. That one was a real B*. It would give me an ok flame but would pulse for some reason where the other orifice worked fine after drilling it once to 3/32".