Musketear

Well-Known Member

I am just about to start construction a 3-tier sanke keg brew tower, but I am having trouble finding something that will provide effect, but neat insulation for the MLT and HLT. What are people using successfully?

no idea on quality but harbo freight has a welders blanket for about 40

I just looked at one while I was at HF... they are not much thicker than a canvass tarp so it might take several wraps of one to provide any insulating value. Still interested to see how your carbon fiber jacket works out, Catt.

Just got mine setup tonight for a run tomorrow... doing ~20 gallons of Cream Ale so this should be a pretty good test of it.

I will report back tomorrow with numbers.

Catt22,

who has this carbon blanket material and where can I get some?

Thanks. Carl.......

Hey Carl,

Mytarp.com is where I bought it:

http://www.mytarp.com/4-x-6-velvet-shield-welding-blanket-hd.aspx

They will also custom cut the material to your specs, but I do not know what that might cost.

Function and durability outweighs cost plus future efficiency with brewing.

Any R factor specs on this product?

Thanks Catt; i've a couple of welding blanckets for repelling sparks and slag damage.

Overall anything is better than a bare keggle against ambiant air temps.

I've had great success with McMaster Carr item # 9385K23.

That polyurethane insulation will burst into flames if you try to use it on a direct fired MT.

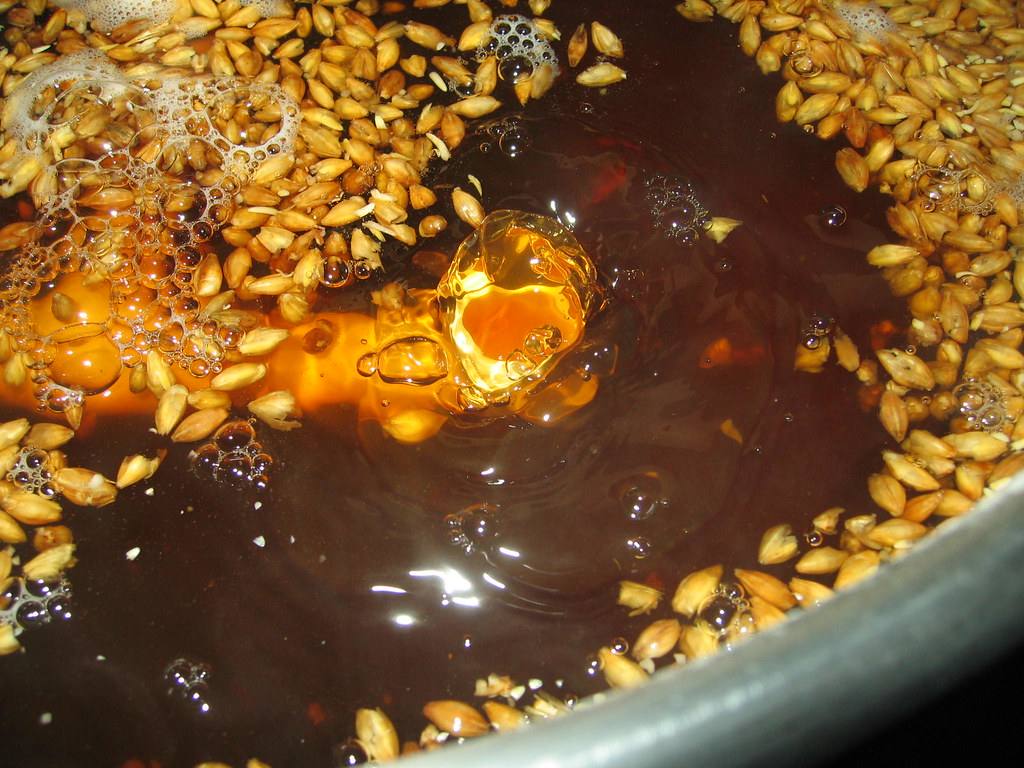

OT, but what's up with your grist? Are those a bunch of uncrushed grains in your mash?

If anyone is looking for these... there are some decent deals on ebay. Just search for "velvet shield" and you will find several of them. If you cut carefully, you can insulate 3 vessels easily with a 4'x6' section.

Enter your email address to join: