FlyGuy

Well-Known Member

After getting used to my keggle and propane burner this summer, it has been hard to go back to stovetop brewing this winter. Last week it almost hit -40, and brewing outdoors just isnt very attractive right now. So I have been back to the stovetop, mostly only 3 gal batches because I havent worked up the energy to do my old split-pot boil routine (i.e., half the wort in each of two 5 gallon pots on the stove).

The problem with my stove, which is a problem shared by many, is that a single burner doesnt throw enough heat to boil all my wort from a 5 gal batch in one pot. Previously, the best I could do was about 3.5 4 gallons in my flat-bottomed stainless pot (uncovered). However, I think I have this problem licked. Tonight I easily got 6.5 gals to a rolling boil in one pot on my stove.

First, I used my cheap 30 qt aluminum pot that came with my propane burner in a cheap turkey fryer kit. I am a big fan of aluminum because it transfers heat better than stainless (see here), and in a water trial, I was able to get 5 gals to a rolling boil in it (significantly better than the SS pot).

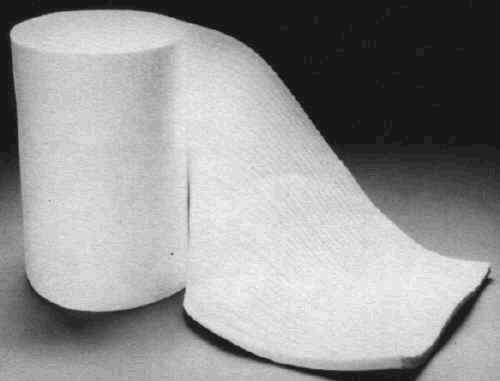

Second, I added a reflective foil blanket to the pot (similar to what many guys drape over their keggle MLTs to keep the heat in). The idea is the same here the reflective insulation helps prevent heat from escaping out the sides of the pot. It was enough to get 6.5 gals to boil instead of only 5 when I used the same pot on the same burner but without the foil blanket.

Here are my old and new pots respectively:

I made the reflective foil blanket out of reflective insulation found at Home Depot. I used two wraps around the pot, and secured everything with foil tape. I cut notches for the pot handles, and then tucked the top and bottom ends under and taped them in place, leaving a good inch gap at the bottom (I was worried that plastic part of the insulation would melt if too close to the burner). I also did a couple of wraps of foil tape around the bottom of the blanket to reflect away heat from the burner. The nice thing about the blanket is that I can easily slip it on or off, e.g. if I want to use this pot outside on the propane burner again. The materials for the blanket cost about $14.

The problem with my stove, which is a problem shared by many, is that a single burner doesnt throw enough heat to boil all my wort from a 5 gal batch in one pot. Previously, the best I could do was about 3.5 4 gallons in my flat-bottomed stainless pot (uncovered). However, I think I have this problem licked. Tonight I easily got 6.5 gals to a rolling boil in one pot on my stove.

First, I used my cheap 30 qt aluminum pot that came with my propane burner in a cheap turkey fryer kit. I am a big fan of aluminum because it transfers heat better than stainless (see here), and in a water trial, I was able to get 5 gals to a rolling boil in it (significantly better than the SS pot).

Second, I added a reflective foil blanket to the pot (similar to what many guys drape over their keggle MLTs to keep the heat in). The idea is the same here the reflective insulation helps prevent heat from escaping out the sides of the pot. It was enough to get 6.5 gals to boil instead of only 5 when I used the same pot on the same burner but without the foil blanket.

Here are my old and new pots respectively:

I made the reflective foil blanket out of reflective insulation found at Home Depot. I used two wraps around the pot, and secured everything with foil tape. I cut notches for the pot handles, and then tucked the top and bottom ends under and taped them in place, leaving a good inch gap at the bottom (I was worried that plastic part of the insulation would melt if too close to the burner). I also did a couple of wraps of foil tape around the bottom of the blanket to reflect away heat from the burner. The nice thing about the blanket is that I can easily slip it on or off, e.g. if I want to use this pot outside on the propane burner again. The materials for the blanket cost about $14.

There's a heads up for those of you shopping for the stuff. I didn't see any other kind when I was at Lowe's yesterday.

There's a heads up for those of you shopping for the stuff. I didn't see any other kind when I was at Lowe's yesterday.