I built one of these to cool my conicals. The evap coil goes in a cooler full of glycol/water and two pumps. Each pump has a temp controller that is monitoring each of my fermenters. The pumps pump the glycol through a copper coil wrapped around the conical. I can control temps within 1* all the way down to 34* even in the summer.

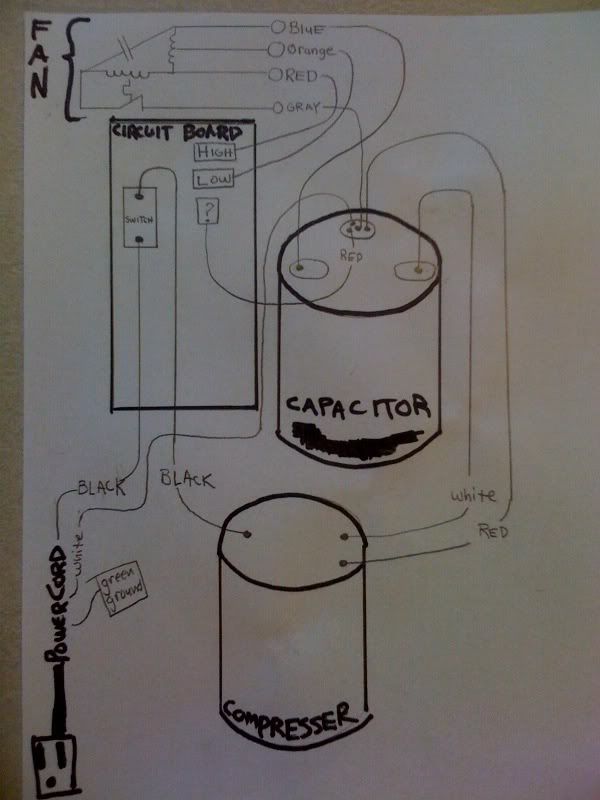

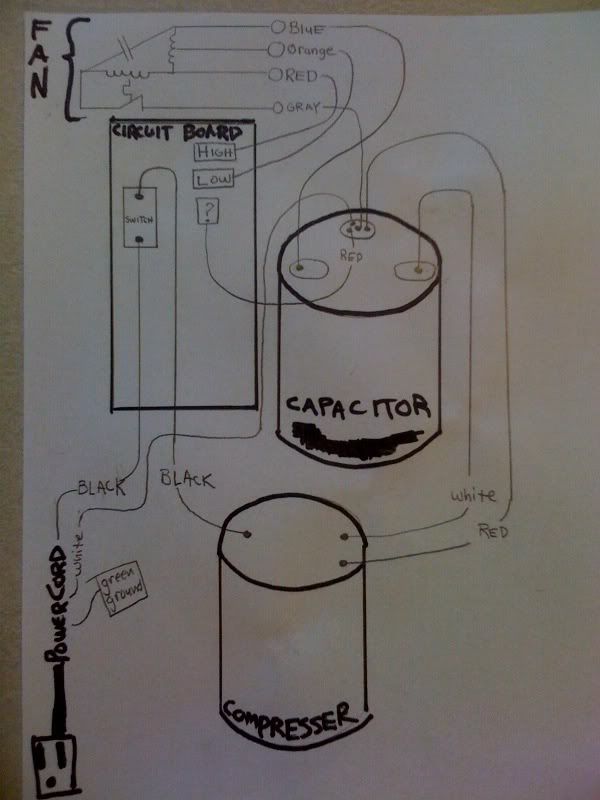

Anyway, for your project you'll need to do away with the electronics board. Are you using a temp controller to monitor the glycol bath? You'll need to. You'll also need a small pump in the glycol bath to keep it moving or it'll still freeze around the evap coil. I also highly recommend you paint the steel part of the evap before you ever get it wet, otherwise it rusts like a ***** and will eventually wreck your circulation pumps. Use the temp controller to connect the black in to the black to compressor and red on fan and one leg of the bath pump. Leave orange on fan disconnected. The temp controller will turn on the fan, pump and compressor at the same time. Connect the other side of the bath pump to the white cluster.

Oh and for chilling wort, I just have another coil inside the glycol bath with a bypass valve. I have hose water straight-thru something like this:

Water in -> shut-off valve->tee to coil -> bypass valve -> tee from coil-> to chiller.

So, for the first 100* or so I leave the bypass valve open. Once I hit ~110*, I shut the bypass valve forcing the water through the coil in the glycol and I can send 32* water to the IC. Make sure you blow all the water out of the coil afterwards or it'll freeze.

DISCLAIMER: I'm not an electrician or an HVAC/R tech. If you follow my advice you could be taking your life into your own hands. Electricity and water or any fluid for that matter are very bad together.