Seems like the builds I've seen so far have X feet of chord coming out of their kettle then plugging into their control box.

I would like the disconnect to be at the kettle so I can clean the kettle out in my sink, versus cleaning in place. Sure I could still clean a kettle with x feet of chord hanging from it but this way would be less clumsy.

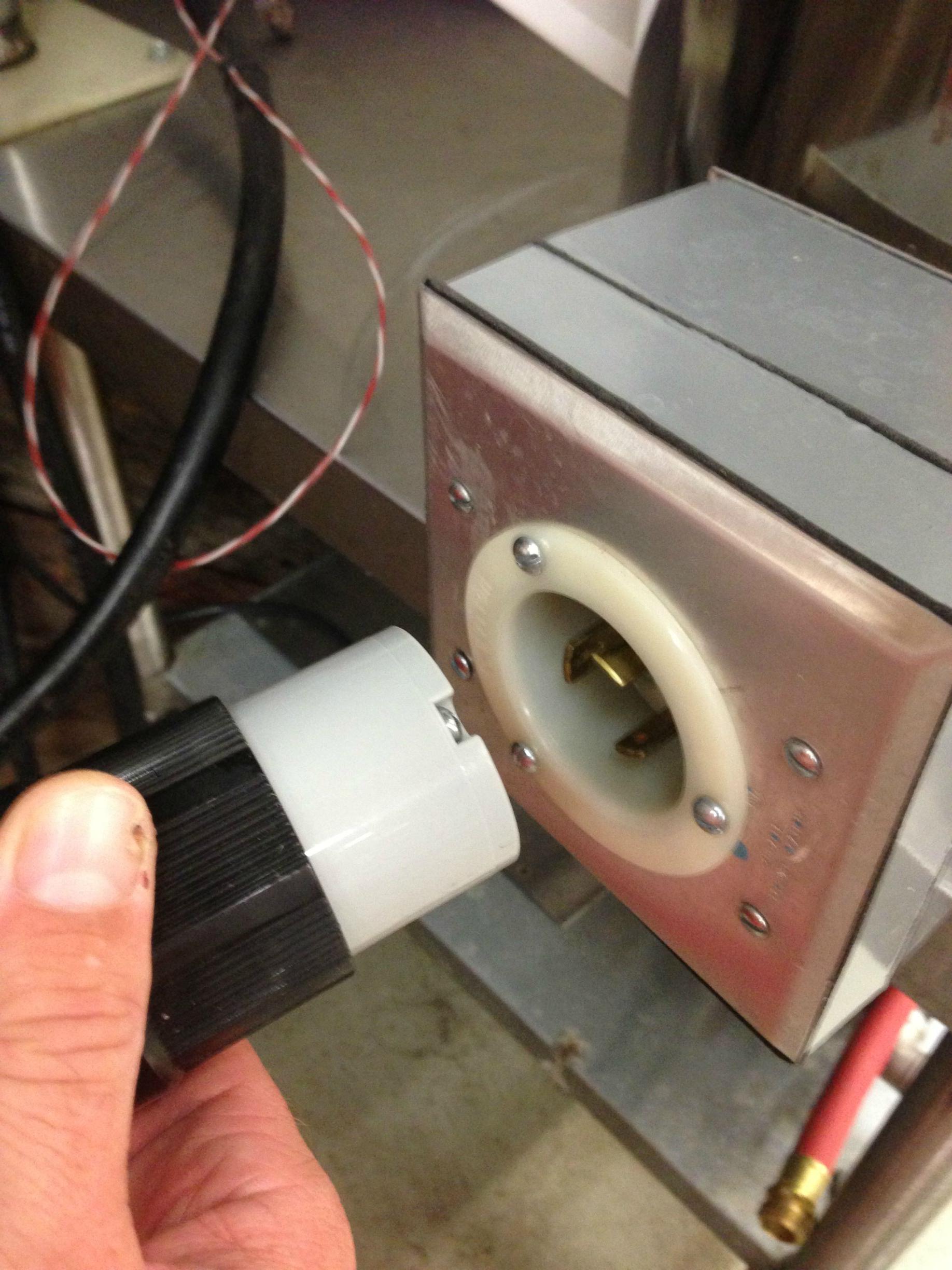

In this approach, I would have the power cord hard wired to the panel > then ~10' of chord > then a female plug (since hot can't be male's) > that connects to a 4" chord with male plug on the box attached to the kettle.

Am I missing some reason why more people don't do this. Maybe Kal will chime in

I would like the disconnect to be at the kettle so I can clean the kettle out in my sink, versus cleaning in place. Sure I could still clean a kettle with x feet of chord hanging from it but this way would be less clumsy.

In this approach, I would have the power cord hard wired to the panel > then ~10' of chord > then a female plug (since hot can't be male's) > that connects to a 4" chord with male plug on the box attached to the kettle.

Am I missing some reason why more people don't do this. Maybe Kal will chime in

![IMG_20130902_123323_632[1].jpg IMG_20130902_123323_632[1].jpg](https://cdn.homebrewtalk.com/data/attach/121/121961-IMG-20130902-123323-632-1-.jpg)