So I got my cheap Sestos PID coming and started looking at mounting the probe. To make it universal between my keggles I was going to mount it on the pump outlet and whirlpool back into the HLT, recirc to the MLT, and whirlpool the BK at the end of the boil (using the PID to just monitor the temp).

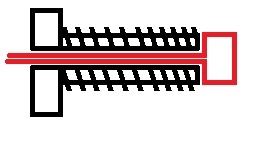

Then I saw the cheap 1/4-20 thread thermocouples that come free with the PID have the anoying "back nut" arangment, i.e. the TC probe is sitting loose in the nut and will no be liquid tight at all

I have seen some use JB weld to seal the TC probe, has anyone done something else?

I was thinking maybe tap the side of a socket to accept a bolt and then tap the bolt for the TC probe, or just tap the socket to just before it breaks through. Just don't know how much this would cause the temp to lag due to the socket needing to heat up first.

Anyone got any other suggestions?

Then I saw the cheap 1/4-20 thread thermocouples that come free with the PID have the anoying "back nut" arangment, i.e. the TC probe is sitting loose in the nut and will no be liquid tight at all

I have seen some use JB weld to seal the TC probe, has anyone done something else?

I was thinking maybe tap the side of a socket to accept a bolt and then tap the bolt for the TC probe, or just tap the socket to just before it breaks through. Just don't know how much this would cause the temp to lag due to the socket needing to heat up first.

Anyone got any other suggestions?