I read the thread, looked at all of the different designs, learned the ins and outs of sketchup, and began my quest.

Thanks to everyone on HomeBrewtalk.com for the "keezer" ideas...

I started with the sketchup file jeezer was kind enough to send me, but quickly realized I need to make numerous modifications so I started a brand new sketchup file and put the major components in place (virtually).

Here is a picture of my original file:

As I build I am making modifications and will periodically update the model.

You can download the entire model from the sketchup model warehouse here:

http://tinyurl.com/7ynx6ys

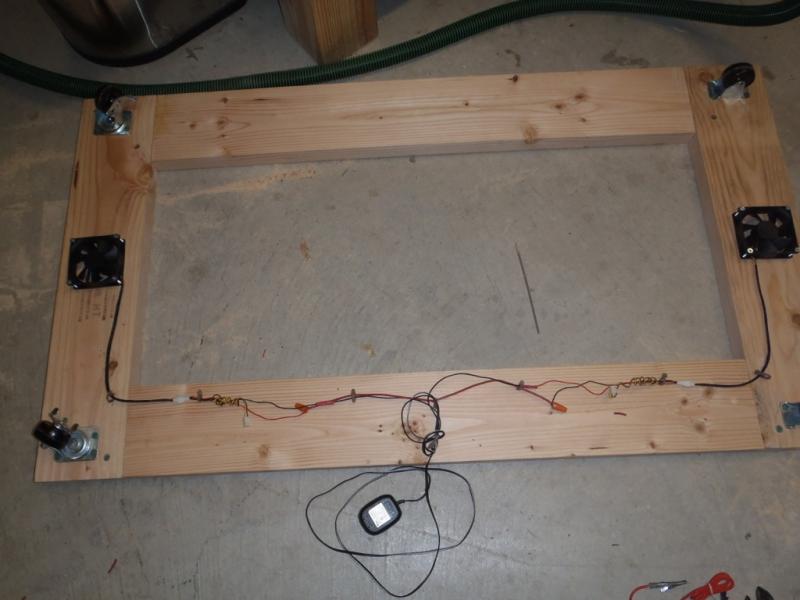

Build pictures coming soon!

Thanks to everyone on HomeBrewtalk.com for the "keezer" ideas...

I started with the sketchup file jeezer was kind enough to send me, but quickly realized I need to make numerous modifications so I started a brand new sketchup file and put the major components in place (virtually).

Here is a picture of my original file:

As I build I am making modifications and will periodically update the model.

You can download the entire model from the sketchup model warehouse here:

http://tinyurl.com/7ynx6ys

Build pictures coming soon!