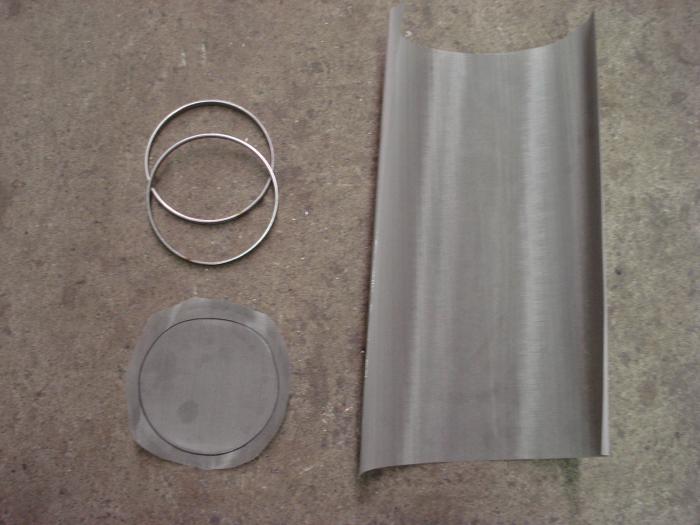

I just ordered a 4x11 filter with 300 microns. Chad was great with communication, and replied back quickly. He's going to try and get my order in this weekend, but it sounds like he has a lot of orders to do. I paid an extra 10 bucks for it over the advertised ebay listing as it was a custom order.

I can't wait to try it out! only thing I am concerned about is fitting my wort chiller in my 11 gal pot with it. I figure I'll put it inside of it when I start sanitizing. I'm sure it'll be fine.

Also, thanks mods for keeping this civil!

I can't wait to try it out! only thing I am concerned about is fitting my wort chiller in my 11 gal pot with it. I figure I'll put it inside of it when I start sanitizing. I'm sure it'll be fine.

Also, thanks mods for keeping this civil!