Ciao

Hi Im an Italian Homebrewer and I got lot of my inspiration for my DIY project from the forum pages In Italy the hombrewer community is far away from certain incredible realization but nevertheless I would like to share my experience in building a thermostatic fermentation chamber using TEC (peltier) module

The reason for such an approach are well known..

-No mechanical part with maintenance like normal compressor

-No hysteresis in switching on and off the engine

-Both cooling and heating capability

-Low Noise, compact size implementation

There are also many disadvantages starting from efficency

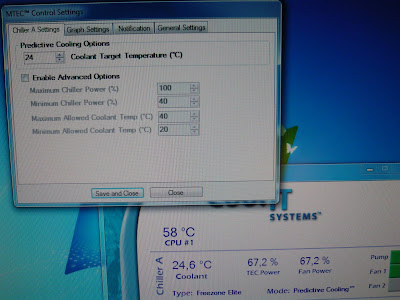

The most attractive feature for me is the capability to drive the TEC module with a programmable electronic circuit that is capable to revert the polarity (h bridge circuit) and to modulate via PWM the power with a fine PID control. With this solution Im able to cool or heat the chamber in a very effective way and try to have a constant range of temperature regardless external temperature (my cellar is very cool in winter and to hot in summer)

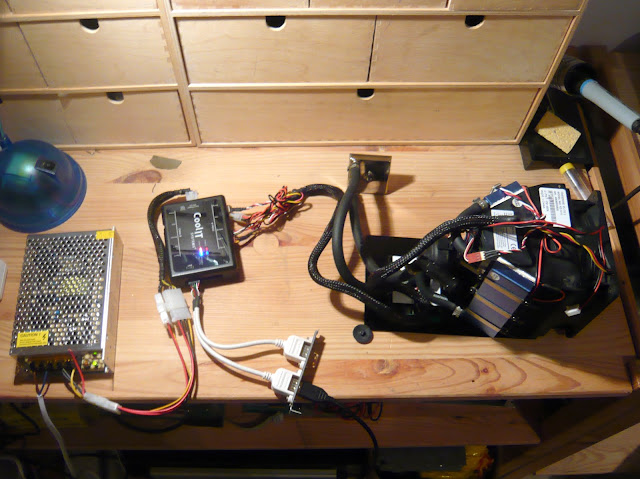

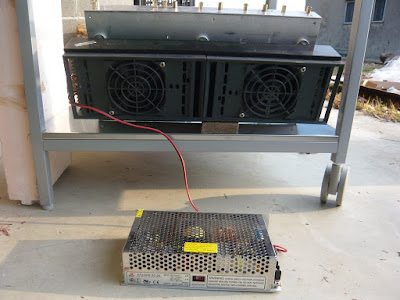

The TEC module was based on 4 x120W cells driven by 24V source PWM modulated. It has been assembled by myself adding 2 heat sink and 2 fan on both side.

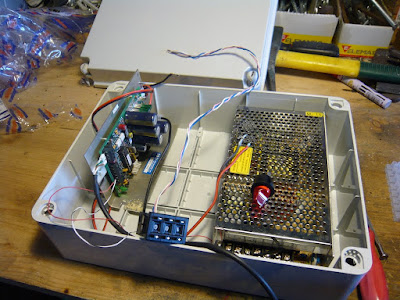

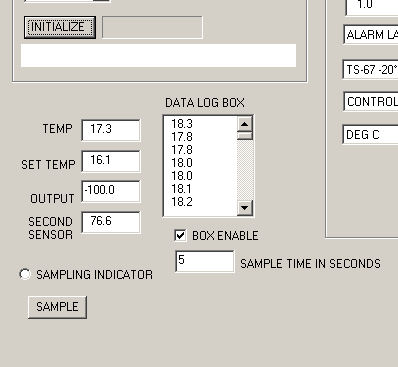

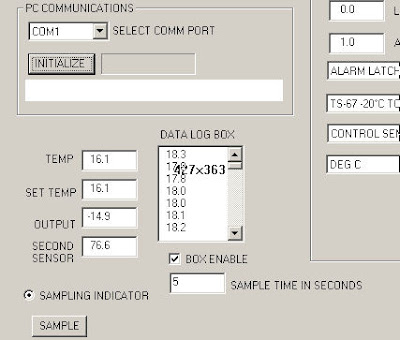

The electronic circuit to drive the TEC module is passed on TeTech TC-36-25-RS232 that uses solid-state MOSFET devices in an electrical "H" bridge configuration to automatically control the direction of current simply based on the temperature set point. The controller can be communicated with and programmed directly through a personal computers RS232 serial communication port

Here you can find all the picture of the fermentation cabinet and the assembling

https://picasaweb.google.com/mysobr...icaACelleDiPeltier?authuser=0&feat=directlink

The cabinet is based on IKEA trolley its stainless steal, robust, light and perfect for 50L fermentation bucket

For insulating I have used some polyurethane panel 2CM thick inserted in the cabinet frame connect with hot glue.

Than I have applied an external and internal thin plastic panel in order to further insulate and have an internal clean surface.

On the bottom I have inserted the TEC module opening a proper hole in the insulating panel

Finally I have sealed all the split with a specific foam

The top cover can be removed as well the front door kept on its own place with super magnet

Im in the final stage and I have to insert in a proper enclosure the power supply and the control circuit as well a thermometer

Its not and AAA+ refrigerator but it looks nice ..isnt it?

When everything is completed I will start to tune PID and software parameter and I will share the result in term of performance and stability

Any comment is off course appreciated.. sorry for my English !

Stay tuned

Davide

Hi Im an Italian Homebrewer and I got lot of my inspiration for my DIY project from the forum pages In Italy the hombrewer community is far away from certain incredible realization but nevertheless I would like to share my experience in building a thermostatic fermentation chamber using TEC (peltier) module

The reason for such an approach are well known..

-No mechanical part with maintenance like normal compressor

-No hysteresis in switching on and off the engine

-Both cooling and heating capability

-Low Noise, compact size implementation

There are also many disadvantages starting from efficency

The most attractive feature for me is the capability to drive the TEC module with a programmable electronic circuit that is capable to revert the polarity (h bridge circuit) and to modulate via PWM the power with a fine PID control. With this solution Im able to cool or heat the chamber in a very effective way and try to have a constant range of temperature regardless external temperature (my cellar is very cool in winter and to hot in summer)

The TEC module was based on 4 x120W cells driven by 24V source PWM modulated. It has been assembled by myself adding 2 heat sink and 2 fan on both side.

The electronic circuit to drive the TEC module is passed on TeTech TC-36-25-RS232 that uses solid-state MOSFET devices in an electrical "H" bridge configuration to automatically control the direction of current simply based on the temperature set point. The controller can be communicated with and programmed directly through a personal computers RS232 serial communication port

Here you can find all the picture of the fermentation cabinet and the assembling

https://picasaweb.google.com/mysobr...icaACelleDiPeltier?authuser=0&feat=directlink

The cabinet is based on IKEA trolley its stainless steal, robust, light and perfect for 50L fermentation bucket

For insulating I have used some polyurethane panel 2CM thick inserted in the cabinet frame connect with hot glue.

Than I have applied an external and internal thin plastic panel in order to further insulate and have an internal clean surface.

On the bottom I have inserted the TEC module opening a proper hole in the insulating panel

Finally I have sealed all the split with a specific foam

The top cover can be removed as well the front door kept on its own place with super magnet

Im in the final stage and I have to insert in a proper enclosure the power supply and the control circuit as well a thermometer

Its not and AAA+ refrigerator but it looks nice ..isnt it?

When everything is completed I will start to tune PID and software parameter and I will share the result in term of performance and stability

Any comment is off course appreciated.. sorry for my English !

Stay tuned

Davide