kal

Well-Known Member

Hi everyone,

In the process of putting together a kegging system with the following parameters:

Distance from kegs to taps: 15'

Height differential: + 3' (taps are 3' higher than kegs)

Beer Temp: around 36-40 F

Using these balancing instructions I get the following:

With 1/4" ID hose (0.7 resistance):

Regulature Pressure = (15 * 0.7) + (3 * 0.5) = 12 psi

Sounds about right where I want to have the beer carbonated from what I've read (10-15 psi seems 'normal' for most styles), but with 1/4" hose I'm losing about 5 oz of beer in the line as it'll likely be warm (not good). So how about 3/16" hose?

With 3/16" ID hose (2.7 resistance):

Regulature Pressure = (15 * 2.7) + (3 * 0.5) = 42 psi !!

42 psi from what I've read sounds WAAY too high!

But I'd only use about 2.5 oz of beer this way...

I can't:

- move the taps any closer to the keg freezer

- raise the freezer significantly

- chill the lines

Am I missing something here? Am I basically forced to use 1/4" hose?

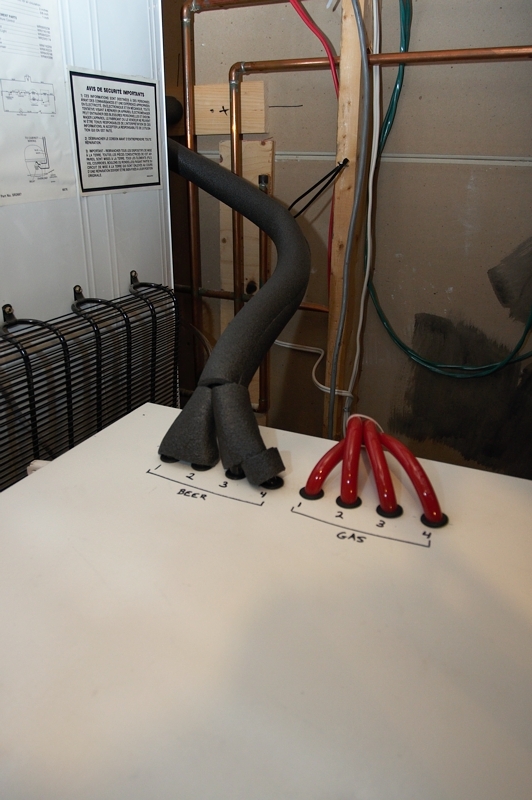

Here's my layout:

The freezer goes in the back room behind the in-wall fridge and the tap tower is going on the left side of the bar (near the beer mug wall). The lines will run inside the curved bar.

Thanks!

Kal

In the process of putting together a kegging system with the following parameters:

Distance from kegs to taps: 15'

Height differential: + 3' (taps are 3' higher than kegs)

Beer Temp: around 36-40 F

Using these balancing instructions I get the following:

With 1/4" ID hose (0.7 resistance):

Regulature Pressure = (15 * 0.7) + (3 * 0.5) = 12 psi

Sounds about right where I want to have the beer carbonated from what I've read (10-15 psi seems 'normal' for most styles), but with 1/4" hose I'm losing about 5 oz of beer in the line as it'll likely be warm (not good). So how about 3/16" hose?

With 3/16" ID hose (2.7 resistance):

Regulature Pressure = (15 * 2.7) + (3 * 0.5) = 42 psi !!

42 psi from what I've read sounds WAAY too high!

But I'd only use about 2.5 oz of beer this way...

I can't:

- move the taps any closer to the keg freezer

- raise the freezer significantly

- chill the lines

Am I missing something here? Am I basically forced to use 1/4" hose?

Here's my layout:

The freezer goes in the back room behind the in-wall fridge and the tap tower is going on the left side of the bar (near the beer mug wall). The lines will run inside the curved bar.

Thanks!

Kal