cruelkix

Well-Known Member

So I've decided to go Nano. I've started to build the new rig and figured I would document it here.

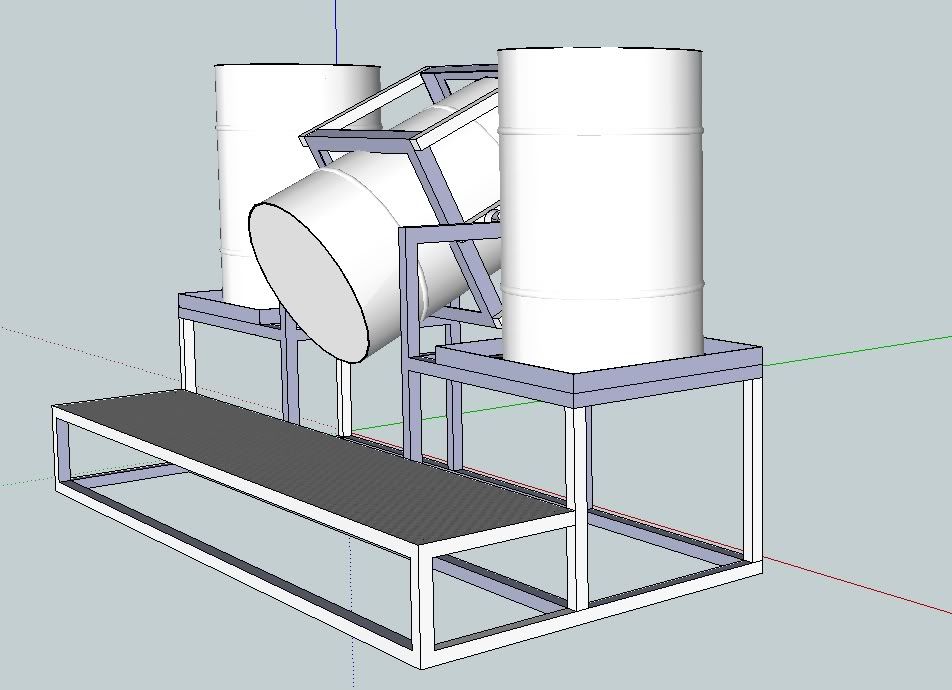

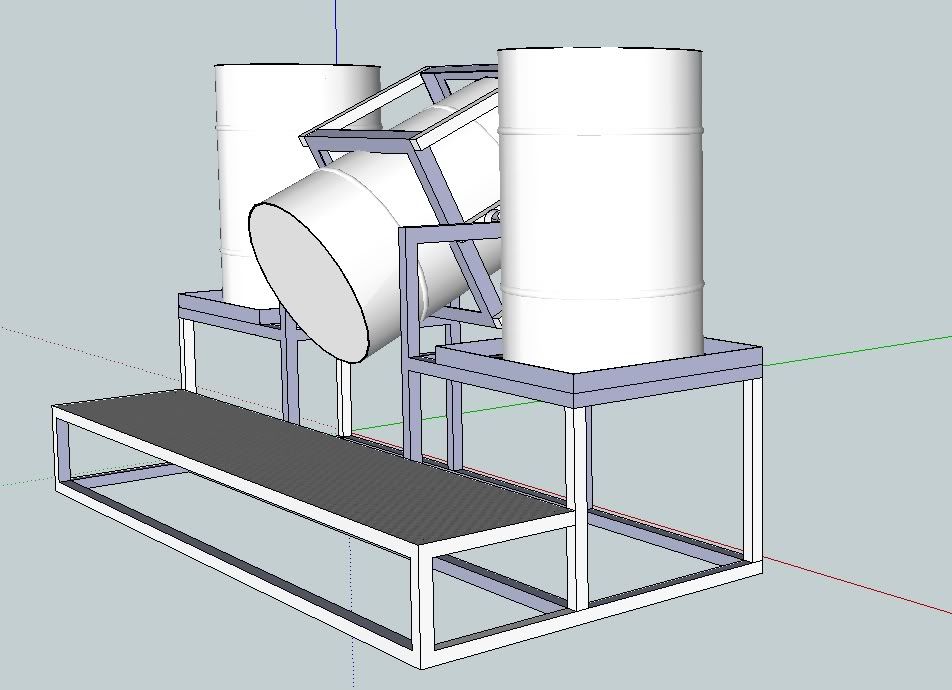

Here's the google sketchup I started with:

From there it was time to learn to weld. I bought a really crappy MIG welder to build the frame and got the 55 gallon stainless steel drums of Ebay. 3 for $750 shipped. I've heard of others getting better deals, but its the best I could find at the time.

Here's the rig where it sits right now. Lots left to do. This pic really makes the bottom beam look like its bending.... It doesnt look like that in real life.

And a quick video of the Tippy Dumpy in action. Still need to figure out how to make it NOT swing while I'm brewing.

Some close ups of the hubs I got off a front wheel drive car at a junk yard.

And a comparison pic of my keggle system vs the 55 gallon system. Pour little guy is all jealous of its big brother

And I'll be using 1" tri clover fittings through out.

Thoughts?

Here's the google sketchup I started with:

From there it was time to learn to weld. I bought a really crappy MIG welder to build the frame and got the 55 gallon stainless steel drums of Ebay. 3 for $750 shipped. I've heard of others getting better deals, but its the best I could find at the time.

Here's the rig where it sits right now. Lots left to do. This pic really makes the bottom beam look like its bending.... It doesnt look like that in real life.

And a quick video of the Tippy Dumpy in action. Still need to figure out how to make it NOT swing while I'm brewing.

Some close ups of the hubs I got off a front wheel drive car at a junk yard.

And a comparison pic of my keggle system vs the 55 gallon system. Pour little guy is all jealous of its big brother

And I'll be using 1" tri clover fittings through out.

Thoughts?